That Mouthwatering Cheesecake on My Plate is 3D Printed!

3D printing has revolutionized the manufacturing industry, from construction to healthcare, automotive to designing. But in recent times, the cutting-edge technology has been applied in additive manufacturing in the lucrative food industry, easily one of the largest growing and popular sectors, be it in terms of taste, quality, or most importantly health and nutrition.

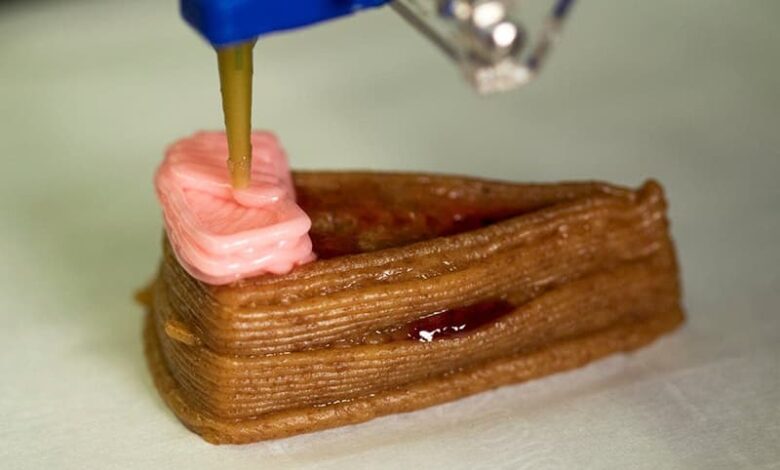

3D printed food business has been gaining traction in recent times and is for real, almost on the verge of transforming conventional restaurant kitchens across the world. The growing popularity of molecular gastronomy, a culinary trend that focuses on the science and principles behind cooking and food preparation, is driving demand for 3D printed products. Also called food layered manufacture (FLM), this novel way of making food digitally applies the additive manufacturing method to food fabrication.

A report by Washington DC-based market research firm Vantage Market Research sees the global market for 3D printed food grow to a total value of $872.4 million, at an impressive CAGR of 49.9% through to 2028.

Extensive Research

Besides its decent adoption in the global food industry, there’s extensive research on 3D food printing going on. While engineers in Columbia University have been conducting experiments related to 3D printed food and food printers since 2005, including whipping up a seven-ingredient vegan cheesecake, Singapore’s Khoo Teck Puat Hospital (KTPH) has been working closely with the Nanyang Technological University (NTU) and the Singapore University of Technology and Design (SUTD) on multiple 3D food printing research projects. In 2013, American aeronautics and space research giant NASA had announced its possibility of experimenting with 3D printing technology for food to overcome the challenges faced by astronauts on long missions.

Popular Choices

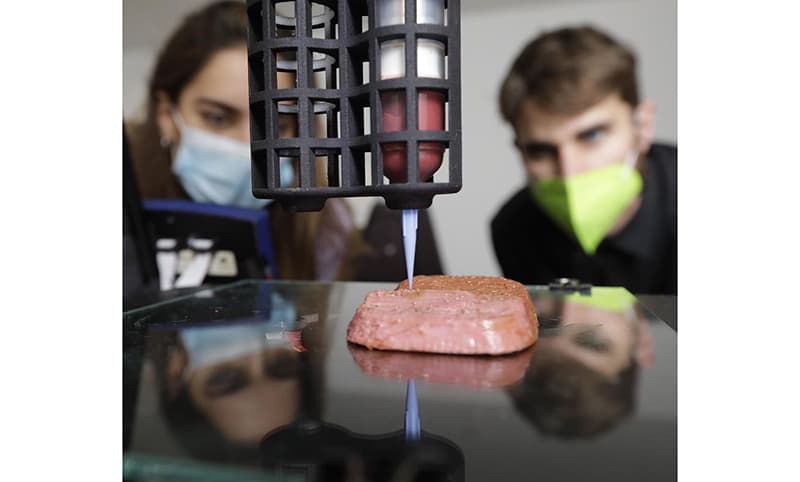

Some of the most popular 3D printed foods in the world include cultured meat, where a stem-cell based bioreactor is used to culture animal cells without harming the animals. It is then printed with inkjet food printers. So gourmets can enjoy their perfect animal-free fish fillet or beef steak with a clear conscience! Chocolates are another popular item and are one of the easiest materials to print using 3D technology, since it can be melted and solidified again rather quickly. Pasta is another global favourite, 3D printed with the most complex designs to create a unique culinary experience.

Market Challenges

The 3D printed food market has its own share of challenges, such as high cost of equipment, the need for specialized knowledge and training, and regulatory hurdles related to food safety and labeling requirements. In this backdrop, it has been reported that scientists in China and Singapore have developed a new upcycled plant-based 3D printing ink, which will help to further reduce costs.

World’s Top 3D Food Printing Businesses

However, with costs dipping with evolving technology, and regulatory agencies developing standards to help ensure the safety of 3D printed foods, many global companies have taken a plunge into the 3D printed food business in a big way. Truly appetizing meat alternatives, gorgeous sugar creations, and sculptural chocolates are attracting consumers and investors to the top companies in 3D printed food today.

Barilla (Italy), the world’s largest pasta company; Natural Machines (Spain), developer of a 3D food printer called Foodini; Novameat (Spain), which created a 3D printed plant-based beefsteak; Revo Foods (Austria) that raised $1.5 million for market entry with their plant-based pea protein and citrus fiber seafood alternative; startup company Steakholder Foods (Israel) that created the world’s first-ever ready to cook 3D printed fish fillet in collaboration with Singapore’s sustainable food production company Umami Meats; Redefine Meat (Israel), that combines 3D printing technology with meat digital modeling and food formulations; byFlow (The Netherlands), one of the most popular global companies working on food printing, focusing on a collection of ready-to-print recipes such as chocolate ganache, meringue, and savoury dips; and Upprinting Food (The Netherlands) fighting food waste by turning rejected or unused ingredients into 3D printable purees, are some of the world’s leading companies in 3D food printing.

Taste, Health, and Other Benefits

Numerous companies are now using the technology to produce both plant-based and cultivated meat. With health and fitness being the top priorities for people in the post-COVID era, increasing consumer interest in meat alternatives have become significant drivers of innovation in the 3D printed food sector.

But will throwing away the traditional forms of cooking jeopardize the taste for gastronomers? Arik Kaufman, CEO of Steakholder Foods, says, “Steaks printed now do not have the exact same taste and texture as the real thing, but I am confident in getting there in the next decade.” Depending on the ingredients, 3D printed food can be sweet, sour, or spicy and can be delicious if made correctly. Printed chocolates and desserts tastes great, while 3D printed meat products won’t give that same delicious taste.

3D printed food has several benefits that are driving growth in the industry. 3D printing allows chefs and cooks to customize their creations, experimenting with textures and designs. For the health conscious, food inks can be formulated to provide the exact amount of vitamins, nutrients, and calories per meal for individual meals. For people with dysphagia, researchers from Australia’s University of Technology Sydney have developed 3D printed pureed food in solid form that is easier to swallow. While plant-based meat for vegetarians presents the same texture, taste, and even smell of real meat, scientists in Japan have 3D printed a cut of Wagyu beef that looks exactly like the real cut using biomaterials that created the exact shape and composition of the original beef steak. 3D printing of food also uses the exact amount of ingredients required, so no material is wasted. Also, wasted food can be recycled by being a material source for 3D printed food. As an experiment, unusual-looking but nutritious plants or protein-rich insects such as crickets can be 3D printed into more attractive food products with appealing textures and flavours.

And with health experts vouching for personalized nutrition, with better control and tailoring of nutrition, printed food is on its way, a natural consequence of software meeting the archaic, analogue world of cookers, frying pans, and steamers. Undoubtedly, 3D food printing is working towards a possible cooking renaissance, one where fresh produce and unconventional combinations are created through an automated process.

Jonathan Blutinger, a food robotics engineer at Columbia University’s Creative Machines Lab in New York, sums it all up, “I think its inevitability. Once software touches an industry, we don’t look back. It propels it forward in ways we never thought possible. The vision is to have a food printer mixed with a laser cooker that can be a one-stop-shop sort of kitchen appliance. It’s your own personal chef. ”