New Perfect Binder From Muller Martini

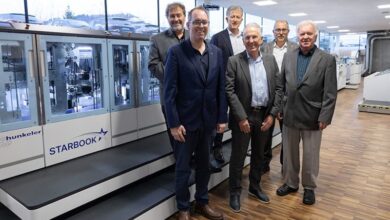

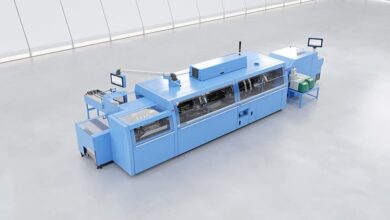

Muller Martini unveiled its new Vareo perfect binder, which is designed for processing digital and offset products, at Hunkeler Innovationdays held in Lucerne from February 23 to 26. According to Muller Martini the new kit represents a technological breakthrough as the first perfect binder where each of the three clamps is equipped with its own servo motor and is driven individually. Every processing step can be individually adapted to the product to ensure optimal quality and high productivity.

Until now, there have been two types of drive for perfect binders, both based on a number of clamps on a chain being driven by a motor. With continuous drive, the motor is always running when the perfect binder is in operation, and all the clamps are in motion. The benefit is a level of high output, depending on the number of cycles. A perfect binder with discontinuous drive runs and stops intermittently. In other words, the clamps do not run all the time. Advantage: the nipping time is set individually, enabling the binding quality to be influenced directly.

With unit drive technology for every clamp, Muller Martini’s new three-clamp Vareo perfect binder is the first to combine the benefits of both technologies. The asynchronous motions of the Vareo mean that every processing step can take place exactly when necessary to achieve the best possible quality of the end product.