Hot Trends And Technologies At SGI 2015

Sign and Graphic imaging Middle East will be held from 11 to 13 January 2015. It is the biggest signage and digital printing show in the region. This year once again the major suppliers and manufacturers of large format printing and digital signage are exhibiting their latest offerings. In this article Dr. Nicholas Hellmuth from FLAAR Reports offers some insight about trends and technologies that dominate LFP industry. Many of these technologies will be displayed at the show.

Memjet, MEMS Printhead Technology

Memjet uses MEMS printhead technology. Five companies offer 42” wide-format printers using Memjet printheads. One of the brands which I have tested is OWN-X, now RTI Vortex, available through Saga Digital. The other brands I would need to have available to test before I can evaluate them.

Memjet technology is still new; available only in dye ink. The next generation printhead, if it offers back-up nozzles and pigmented ink, should be more practical out in the real world. But for CAD, GIS, or quick proofs of giant panorama photos, even this initial general of Memjet printers is worth looking at. Making your prints more dimensional than merely flat. As more and more signage switches to dynamic digital technology on LED at giant size or LCD in shopping centers, hotels and airports, the best way to increase your profits is to gradually evolve to producing signage which is more eye-catching than a mere billboard.

If you can add multi-dimensional effects, real or pseudo, you provide more potential for your clients. There are at least three kinds of deep-relief wide-format printable images.

If you can add multi-dimensional effects, real or pseudo, you provide more potential for your clients. There are at least three kinds of deep-relief wide-format printable images.

Thermo-formed is visible with Efi VUTEk printers. Here you use a special ink but on most normal UV-curable printers. You then need a vacuum heat press to thermo-form the images around a mold (you also need to make a mold for any shape you prefer, of wood or heat-resistant material). Also Fujifilm is planning to showcase thermoforming application during SGI. The company will also display for the first time in the region the Acuity flatbed 4006 printer.The double size print bed on X2 models has dual registration points which enable you to print at one end whilst setting up at the other, for uninterrupted production. It also enables you to print large images up to 2.5 x 3.05m.Fujifilm will also put on display Fujifilm LED 1600, F 1600 vibrant which is an OEM machine, made by Mimaki. It uses SUV inks. Solvent UV ink prints as normal solvent ink but then 1 meter later cures with UV-curing. It is called SUV ink. All the ink is known to obviously be from a single company. But we have now found one additional SUV ink manufacturer and it will be interesting to see if this newest SUV ink is available in Dubai at SGI 2015.

Curiously, there was zero SUV and zero latex ink printers in the Mimaki booth at APPPEXPO in Shanghai this July. But there was a Chinese latex and another brand of SUV (not Mimaki, not HP).

A dozen Chinese companies have produced low-bid material which tries hard to look multi-dimensional. I call these materials “Bubble-wrap.” The most effective is from Korea, by Mireco. As with thermal formed images your graphic designers will need to understand how to use software to create the images which look most effective with these pseudo-3D substrates. Any ink can do these, even on roll-to-roll materials. So a dedicated flatbed is not absolutely essential.

A third manner of producing innovative relief is to vary the depth of ink to provide a true dimensional effect. Six years ago Sun Innovations showed this kind of ink layering effects around the world. But this company has not exhibited even in Russia the past two years. I have seen deep relief in the booth of Dilli. Occasionally displays of print samples in the booth of Fujifilm (Oce Arizona) and Mimaki exhibit such effects, but so far no one focuses on these effects as much as the former Sun Innovations.

A third manner of producing innovative relief is to vary the depth of ink to provide a true dimensional effect. Six years ago Sun Innovations showed this kind of ink layering effects around the world. But this company has not exhibited even in Russia the past two years. I have seen deep relief in the booth of Dilli. Occasionally displays of print samples in the booth of Fujifilm (Oce Arizona) and Mimaki exhibit such effects, but so far no one focuses on these effects as much as the former Sun Innovations.

You need a dedicated flatbed plus a precise printhead carriage system to be sure that each layer is precisely over the previous layer. And your image software must tell the printer firmware or RIP where to put each layer. You don’t want all the layers of the entire image to be the same depth.

Innovative Media & Substrates

Pablo Martinez of FLAAR handles media and substrates but at APPPEXPO in Shanghai I made time to inspect the current situation in wide-format media. I was frankly impressed at the diversity of media, especially for wallpaper and diverse kinds of fabric (thick as well as thin; the thick weaves were very “visual” and handsome).

When I visit printshops around the world I notice that most tend to limit themselves to the basic standard media to which they are already accustomed (since it is time consuming for them to test new materials).

Another issue is how to know whether the factory in Asia can really consistently deliver material of reliable printing quality. Too many times we have heard that the surface quality varies between one container load and another and that by the third shipment that the media is defective. Print shop owners and distributors say this clearly every year.

The only way we can recommend any media is to visit the factory and then to visit end-users. So we have been to the factory of Yeung Jeou three times and have visited end-users in South Africa who were printing billboards with the PE branded as ARIA.

Textile Printers

Dye sub (for transfer paper) and disperse dye ink (direct to fabric) are not changing much year to year. What is tough to find are reliable models at 3.2meter grand format size. Where changes are hoped for are in having better color pop with pigmented ink for cotton. Hongsam Ink Company is working on this for several years now.

After-Market Inks

There are advantages to ink direct from Canon and Oce, HP, Fujifilm and Mimaki. But after-market inks are increasingly popular. A dozen brands are available in Dubai. Of brands which have been exhibited over the years, I can evaluate the brands when I have been to their ink factory, to their demo room in their company headquarters, and to an end-user: I have been to Sam Ink three times and too many people around the world who use their water-based inks, especially for HP Designjet printers. I have been to the Hongsam factory and we have also visited their demo room in Shanghai three or four times (plus have visited end-users with their textile inks). So these are companies we know.

STS Ink has grown steadily every year for the last four or five years: now they exhibit literally around the world. The owner, partners, and managers are all hard-working and know the world of inkjet inks.

The key to advances in wide-format inkjet printing are in printheads and inks. A good example of advances in high-speed industrial printheads is coming from Samba technology from Dimatix (Spectra). We have been offered training in this Samba printhead technology at the Dimatix demo rooms, so will have more information in the future.

The key to advances in wide-format inkjet printing are in printheads and inks. A good example of advances in high-speed industrial printheads is coming from Samba technology from Dimatix (Spectra). We have been offered training in this Samba printhead technology at the Dimatix demo rooms, so will have more information in the future.

For advances in inks, most really exciting new inks do not do well outside the R&D labs and the demo room. Sepiax is a good example of an impressive ink which still after five years is not in any mainstream printer (but it still exists, hidden in the Marabu booth at really large printer expos).

HP latex ink is now in its third generation and thus improved over earlier prototypes. A Chinese latex ink tried to offer printing on flatbeds but was not able to compete with UV-cured, so Meijet dropped their flat.

In SGI HP will be showcasing HP Latex 310, HP Latex 330 and HP Latex360 Printers and applications. For grand format market HP will put on display HP Latex 3000 Printer and HP Scitex FB700 Industrial Printer and applications. For graphics HP will exhibit HP Designjet Z6600 Production Printer. These machines are already in the market however the number of applications that these printers can handle increase continuously. So we expect to see some nice applications on display at HP booth.

Although it is popularly considered that Chinese ink companies produce only knock-off copies of after-market ink, we have visited the ink factory of Hongsam and they have an innovative resin-like wallpaper ink (meaning NOT solvent). Plus they are advancing with pigmented ink for cotton.

The Attractive Inkjet

Major trade shows, such as SGI are a great place to see the latest innovation in inkjet technology. Without the mind boggling innovations introduced within the inkjet technology advertising industry could not have expanded with such a rapid rate.

It is no coincidence that over the last 18 months many new vendors have appeared on the scene with new inkjet-based products and technologies, just as a growing number of dealers and end-users have decided to find out as much as they can about the product category. Inkjet is a non-impact technology that offers a wide window of opportunity unlimited by size or dimension. Using precision print heads, inkjet systems can place fine dots of ink on virtually any medium that can fit under the heads. If it can be considered a bandwagon technology, graphic communications professionals are jumping on it— and at an impressive rate.

The answer to why inkjet is such an appealing option lies in the fact that the benefits and opportunities of the technology are becoming clearer to the creative, production and print-buying communities. Inkjet is a direct route to creative, cost-effective and profitable printing. It can be customized, proofed on press, and effectively carried out at a very wide array of sites and locations. It can be used with both rigid and flexible media, and delivered with the highest degree of quality.

The answer to why inkjet is such an appealing option lies in the fact that the benefits and opportunities of the technology are becoming clearer to the creative, production and print-buying communities. Inkjet is a direct route to creative, cost-effective and profitable printing. It can be customized, proofed on press, and effectively carried out at a very wide array of sites and locations. It can be used with both rigid and flexible media, and delivered with the highest degree of quality.

Inkjet can turn over many jobs in a short period of time, complementing all other print technologies that printers may currently be using, thereby increasing their overall output. Plus, it is not difficult for most shops and corporate print departments to bring inkjet in-house, even if it hasn’t been part of the overall planning for too long. Inkjet technology is, in essence, thousands of ink droplets landing in exact designated locations on the substrate.

In many ways, the technology is growing even faster than we had anticipated. Today we see inkjet images as advertisements on the sides of buses, as creative labels on oversized boxes and packages, as large backlit displays, as brilliant fine-art reproductions and more. And we are currently laying the foundation for uses as broad as the imagination will allow.

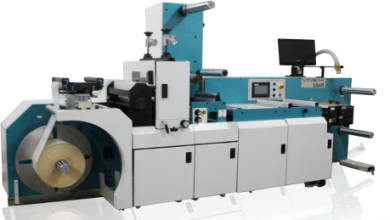

The myriad of application that printers now a days can offer is truly amazing. However when it comes to material today most volume of inkjet printing is on PVC vinyl for building wrap and billboards and all the materials for indoor advertising in malls and airports. But a lot of these traditional signage applications are being replaced by LED electronic signage. So using eco-friendly materials such as PE seems a smart strategy. With the advent flatbed printers, special and industrial inkjet printing is gaining traction. A rising printing trend is currently ceramic tiles and printing on glass. To print applications other than traditional signage, you will tend to need a dedicated flatbed printer. There are now specialized printers for ceramics and glass now.

Trade exhibitions including SGI would be ideal places to see these innovations and large format printing in action.