Grand Format UV Cured Printers

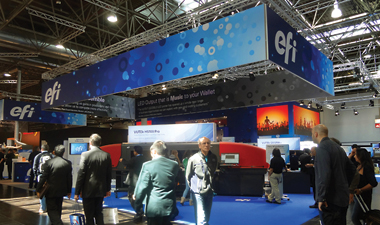

Dr. Nicholas Hellmuth in this article introduces print shop owners to a variety of super wide format printers that are available in the market today. He narrates his visit to the EFI VUTEk headquarters in US and also gives a glimpse on their latest technology and solutions that were presented during drupa 2012

When it comes to the question of choosing a super wide/grand format printer, print shop owners have to deal with a variety of options today. So, I thought that an article that introduces grand format printers available in the signage market would really benefit the print community.

At FLAAR, we often get the opportunity to visit factories of print machinery manufacturers, and witness the machines perform in a real time environment. Recently, I and my colleague Jose Melgar visited the EFI VUTEk headquarters, which is located in Foster City, USA. Today, inkjet printers have a wide market and can be used for various applications. The same applies to EFI. They have an extensive range of product line that includes the Jetrion brand, under the label press category, and the Cretaprint, which is an in-line printer range for the ceramics market. Their VUTEk textile printer has good potential and has the capability to stay in the market for several more years.

The newbie’s at drupa 2012

Though the VUTEk website offers a detailed view of their product range, I will concentrate on some of their latest product lines that were exhibited at drupa 2012, especially the EFI VUTEk HS 100 pro. First, let us take a look at the models that were exhibited during drupa.

Drupa 2012 – ‘The Year of LED Curing’

This time, there were a record number of manufacturers, who presented LED curing lamps, electronics and total solutions at drupa 2012. The demand for a perfect UV curing system is still high in the market. I still remember a UV curing system that was presented by a Swiss printer; the half-a-million dollar Lüscher UV flat bed printer was produced by a non-inkjet print manufacturer. The model had many flaws and it clearly explained how painful the experience can be if you have never produced an inkjet printer before.

The most troubling aspect faced by printers during the initial stages of their product deployment will be regarding their LED curing systems. There is always a difference between a perfect success story and an actual evaluation, because in the real world, no machine operates flawlessly in every aspect.

The most troubling aspect faced by printers during the initial stages of their product deployment will be regarding their LED curing systems. There is always a difference between a perfect success story and an actual evaluation, because in the real world, no machine operates flawlessly in every aspect.

Today, LED curing has advanced considerably. I bet that over 75% of the manufacturers, who produce UV cured printers and who have not yet come up with LED curing solutions are working hard to develop a perfect LED curing system. Sun Innovations is one such company, which has based all its products on LED curing, for several years now.

The lack of LED curing on some of the brands have indeed been a plus for VUTEk, as the print manufacturer already have some experience, both in LED curing and mercury arc curing. VUTEk has been using LED curing in many of its models for the past several years.

The EFI VUTEk GS 3250LX is one of such few printers in the grand format category that uses LED lamp technology. The first models that used LED lamps were in the up to 1.6 meter wide printer category, such as the Roland VersaUV LEC, VersaUV LEJ series, the Mimaki UJV-160, and the Mimaki JFX-1631 printer. The number of UV print manufacturers, who are willing to try LED technology is growing. At drupa 2012, I saw at least 13 UV printer models using LED lamps.

In spite of being a drupa year, EFI launched a new 3.2 meter wide hybrid printer- the EFI R3225- at ISA Sign Expo 2012. They had exhibited its ancestor- the EFI Rastek R3204- a year before at the ISA 2011. Although the R3204 is exclusively designed to handle roll-to-roll media, we can classify this printer under the hybrid category, as it moves media using a pinch roller system. This time, the improved version is neither a Rastek nor a VUTEk series, but is an innovative model concept intended to fill the gap between both these series of printers.

The new R3225 is a much improved version, because instead of having four printheads, it comes with two Tosibha Tec print heads per colour. So, it’s a production-oriented machine than a traditional Rastek, but at the same time has a considerably lower cost than a VUTEk printer. This printer completes the finished printer concept, than the version exhibited a year earlier. Shipping of the machine had started as of from June-July 2012.

Latex vs. Resin vs. UV cured printers

The topic on Latex ink pops in, while discussing anything about drupa 2012 or about UV cured printers. Latex ink printers were well received in the market for several years, but the early adapters were stuck with poor colour gamut and low outdoor longevity. Though, there is an improved second generation ink from Seiko, still the colour pop is less than the solvent ink, which was developed by Seiko ColorPainter. Apart from that, the enormous heat required for curing means that using latex can be expensive. Plus, some people point out that it takes a long time to warm a latex printer, in order to produce a usable output. It’s also a fact that most kind of media used can’t bear the extreme curing temperatures.

It was also great to see some new generation latex inks from Mimaki. These inks are not yet being shipped, and there is no independent documentation of how they function in the real world. Roland and two other Japanese companies have been in the process of developing latex ink printers for several years now, but the Japanese companies were clever enough not to show them to the public, as they are very slow (the curing takes a long time). By far, the Japanese latex inks are too expensive and it is estimated that latex ink printers will still be a ‘concept under development’ till 2013. The fascinating latex prototype printers continue to attract people to the exhibitor’s booth, but those deployed in the signage printing shops have many limitations.

It was also great to see some new generation latex inks from Mimaki. These inks are not yet being shipped, and there is no independent documentation of how they function in the real world. Roland and two other Japanese companies have been in the process of developing latex ink printers for several years now, but the Japanese companies were clever enough not to show them to the public, as they are very slow (the curing takes a long time). By far, the Japanese latex inks are too expensive and it is estimated that latex ink printers will still be a ‘concept under development’ till 2013. The fascinating latex prototype printers continue to attract people to the exhibitor’s booth, but those deployed in the signage printing shops have many limitations.

AquaRes resin ink was one of my favorite, when it first came out in 2008. But during the last four years, it has been documented as not functioning adequately on PVC and being very slow on some other materials. The first generation of white resin ink was not usable in the real printing scenario. There were several other significant issues related to resin inks, which apparently led signage printers to declare that resin inks are not suitable for signage printing, especially for the grand format size. We hope that further R&D will help to bring a change to this situation. But currently, resin inks like Sepiax will be primarily useful for highly specialized materials and in situations where speed is not the primary need. Latex inks are still not available for thick or rigid materials, and is not available for 5 meter grand format printers either. So, I would say that UV cured chemistry would continue to dominate the market for the next two years, at least, because it works and most of the manufacturers have plenty of experience working with it.

Clever Curing System

If you are a print shop owner or a manger, then you should experience printing on a demo version of the EFI VUTEk HS100 pro, rather than scanning for its technical details. You can view live performance by visiting any of the EFI demo centres. I was given a peek into the remarkable features of this printer. If you go to a demo centre, they will show you the printer and will explain all the technology benefits of the printer.

It’s preferable that you make an appointment for viewing the demo session, as you can view the printing experience at a leisurely pace, rather than viewing it during the hectic schedule of a trade show. At the demo centre, the operator and the demo centre team would be at their convenience and will be more poised to explain the details, compared to an expo.

Solutions For Everyone

Car manufacturers had long ago learned the trick that if they offer end-users a wide range of price and performance options, it will ultimately help them to boost their overall sales. EFI also goes by this trick. They offer Rastek that appeals the entry level users, while the VUTEk QS and GS solutions appeal the sophisticated print shops, which handle more volume. A new addition to this diversity is the R3225 machine, which was presented at ISA 2011 and during drupa 2012.

What to look before selecting a printer!

Many questions pop out in the mind of print shop owners, before deciding to invest on a printer. For example, one of the question would be – Is the company that sells the printer – the real manufacturer or is the company rebranding a printer made by some other manufacturer? They would also like to know details such as, what experience do the companies have in making grand format printers or are they producing the same core product that someone else has developed earlier?

At least two of the major brands of UV cured printers today are in reality only distributors. Though the companies might have a good name in the market, customers mainly look for the machines that they market, and not what they had invented themselves.

VUTEk has been making printers since the days of air brush machines. The company also makes their own RIP software. EFI knows more about the technological side and firmware of the products. Plus, in the past years, VUTEk had produced inks from their own ink factory. So when they talk about ink, they know about the ink chemistry themselves.

Textile Solutions

While observing the various grand format textile printers in the market, one can notice that making water based textile printer without an Epson printhead is a real challenge. Water-based inks are prone to lot of issues, like generating a chemical mass or smog from the material during the printing process.

Other issues with grand format textile printers include the inexperience of the manufacturers with the workflow of textile print production, especially the inks. VUTEk was well aware of the stumbles and bumbles faced by other textile printers during the last six years. So, they opted for a solvent-based textile printer that creates less ‘smog’. (Though it’s quite ironic that solvent-based textile printers produce less smog than water-based textile printers)

Other issues with grand format textile printers include the inexperience of the manufacturers with the workflow of textile print production, especially the inks. VUTEk was well aware of the stumbles and bumbles faced by other textile printers during the last six years. So, they opted for a solvent-based textile printer that creates less ‘smog’. (Though it’s quite ironic that solvent-based textile printers produce less smog than water-based textile printers)

VUTEk has also worked with their ink supplier to solve the ‘smog’ issue. They have teamed with Hilord, an experienced ink company, who already has experience producing textile inks, and specifically solvent-based textile inks.

There are many other inks available in the market that is suited for textile printing – UV-cured and latex inks for example. But many clients prefer printing with an ink that is compatible with a wide range of polyester fabrics.

EFI at FESPA Barcelona 2012

FESPA 2012 was noticed by the absence of major printer manufacturers (Durst, Jetrix, Dilli, Gandy Digital, MTL Print, Matan, Anderson DPC, and Polytype were missing this time). It is worth mentioning that EFI was one of the few major printer manufacturers, who came with full force at FESPA. This time, they featured the VUTEk 3250r, the VUTEk 3250 LX combo printer, the EFI Rastek H652 printer and the EFI VUTEk TX 3250 r that was displayed in the booth of Hillord.

EFI had also exhibited samples that were printed on the newly acquired Cretaprint, though the machine was not exhibited. However, I was able to examine a new ST model of Cretaprint in May 2012 at the ITMA Asia Expo that was held in Guangzhou, China.

Complete Workflow Solution & Its Advantages

A printer is termed efficient mainly by two factors – its firmware and its RIP. Firmware is the software that handles the instructions from the on-board electronics and ink. Firmware makes a printer perform its basic functions. EFI uses the Orion OS software platform that helps them in improving the performance of its super wide format and inkjet printing systems, and it also offers viable alternatives to screen printing.

RIP is the software that provides more sophisticated instructions to the print heads and helps in colour separation, and fine tuning the quality of the print. EFI is one of the few printer manufacturers, which makes its own RIP software. If you know your firmware inside out, it is easier to make a RIP that can communicate with the firmware (and with the ink system).

RIP is the software that provides more sophisticated instructions to the print heads and helps in colour separation, and fine tuning the quality of the print. EFI is one of the few printer manufacturers, which makes its own RIP software. If you know your firmware inside out, it is easier to make a RIP that can communicate with the firmware (and with the ink system).

The best way for me to summarize is that if you are a large sophisticated print shop (or wish to reach that status) you can do one-stop shopping at the demo centres of EFI in Meredith , New Hampshire in America, or in Europe (or the other VUTEk demo rooms elsewhere in the world).

The next step in software is MIS

A noticeable trend seen during the past years is the availability of additional software that helps print shops in keeping track of incoming orders, as well as tracking the specific cost incurred in producing each print job. Management Information software (MIS) solutions has become a growing industry during the last number of years. As EFI makes it a point to provide the entire workflow for a print shop, MIS software is now obtainable from EFI as well.

Print shop owners in the Middle East can hopefully look forward to see a diverse range of EFI VUTEk solutions at SGI 2013, which will be held from 20th to 22nd January, 2013 at Dubai World Trade Centre.

Your Pick

Every brand and every model has a dominating feature, and there may be one or two faulty features in every product. So to choose your ideal printer, you have to decide the features that you really require, and the features that you can omit.

Make sure that you know your local distributor well. Cross check with other print shops to learn how the manufacturer’s product holds up in the market, and know how the local distributor handles service and support. And once you have installed the new printer, we at FLAAR Reports will always welcome your invitation to visit your print shops- in the Middle East region- and we could check how the equipment is functioning.