FESPA; 50 Years And Not A Bit Tired

One year after the Fespa organisation was born, the first show for large format printing was held in Paris in 1963. At that time only analogue technology such as cylinder printing, semi-automatic presses and screen printing machines were on display. How different this year’s show would have appeared to the original visitors. How far technology has evolved since the first Fespa and how much has changed – or has it changed? Still visitors are flocking to the show and still conferences and additional events are held. Once again, the latest technology was on display and co-located with the European Sign Expo it not only encompassed digital and analogue printing but also digital signage.

One year after the Fespa organisation was born, the first show for large format printing was held in Paris in 1963. At that time only analogue technology such as cylinder printing, semi-automatic presses and screen printing machines were on display. How different this year’s show would have appeared to the original visitors. How far technology has evolved since the first Fespa and how much has changed – or has it changed? Still visitors are flocking to the show and still conferences and additional events are held. Once again, the latest technology was on display and co-located with the European Sign Expo it not only encompassed digital and analogue printing but also digital signage.

While walking the aisles one thing became apparent to everyone: new environmental regulations that have or will come into effect in the upcoming years have changed the industry. Last edition of Fespa still had a multitude of solvent based large format printers on display. London was different: Sure, there are still many suppliers that offer solvent based printers but nearly all of them have not only water-based offerings but also UV and UV-LED or Latex technology in their portfolio. Especially the UV and UV-LED offerings seem to be growing thus enabling many more different applications. Inkjet printing by now not only means to be used in large format graphics but also industrial applications that up to now were dominated by other technologies.

In addition, Fespa saw quite a few players from the digital textile printing sector. This manufacturing area is still largely dominated by screen printing – however, that is bound to change in the next years due to more individualized and personalized services and products that customers expect. By now, print quality and productivity have reached a cross-over mark that enables printers to not only think about but also employ digital textile presses for their projects. The first textile presses that encompass some of the tiring tasks involving finishing are out making the whole cumbersome process easier for printers. Here’s a fresh round up:

New technologies from established brands

Featuring EFI’s Pin & Cure technology that enables precise ink lay-down, even at highest speeds and encompassing gloss control for production on different surface finishes the new VUTEk HS100 Pro greets us at the company’s booth. This high-end 3.2 m wide machine prints at a maximum speed of up to 100 boards/hour.

Abdallah Ghalayini from Saga Digital, Middle East and African distributor for EFI products explains further: “The print quality of the VUTEk HS100 Pro approaches offset quality and significantly reduces turnaround times for display signage and other applications. Printers do not have to settle for just going faster – the machine delivers high end image quality whenever it is running. The machine, as all EFI products, integrates seamlessly into EFI’s print and workflow systems.”

The new EFI Fiery version enables streamlined file preparation as well as reliable colour management and preflighting. Two years ago, EFI introduced the VUTEk GS family with LED curing. The newest model, the VUTEk GS3250LX was shown in London. This machine is especially suited when it comes to printing on vinyl and fabrics due to UV-LEDs decisive low curing temperatures. Fespa also saw the introduction of EFI’s new thermoforming UV inks that enable printing directly onto thermoplastic sheet materials that can then be formed into deep draw, high elongation parts for use on the VUTEk GS-family. “Even after forming, there is an excellent retention of hue and opacity”, says Ghalayini. “The wide selection of media, among them PETG, acrylics, polycarbonates, polystyrenes and PVC enables many new applications within the custom-formed signs, packaging, POP displays, consumer and promotional products markets, to name just a few. The ink layers withstand heat forming, cutting and routing without cracking, chipping or losing adhesion and feature moisture resistance while at the same time lasting a long time.”

Another world first was the introduction of SmartSign Analytics, a tool that via an implemented camera in the display automatically detects key information such as age, gender and how long a person spends to look at a certain graphic. It does not record video, screen captures or personal information of any sort. By using raw data and proprietary algorithms analysis is done for objective purposes. For example which advertising platforms better reach a targeted demographic in a specific location. “SSA has the potential to provide unprecedented insights on the best strategies and execution to drive retail sales”, says Mark McGowan, director of EFI’s OPS products.

HP Scitex FB10000 is the name of the company’s newest industrial press for POP graphics and corrugated displays that up to now are mainly produced using analogue technology. “The HP Scitex FB10000 Industrial press addresses these challenges, enabling print service providers to capture part of the 6-8 billion square meter page opportunity in the retail graphics and corrugated display markets”, says Francois Martin, HP GSB worldwide marketing. Available as 6-colour press it features UV-curing, 16 gray levels and can produce 1,000 B1-sheets in less than two hours (625 sqm/h). “The new press also delivers unmatched media versatility, including acrylics and polypropylene as well as flexible and rigid media. New HP HDR240 Scitex Inks achieve excellent adhesion on a wide media range at high productivity and comply with ISO proofing standards, helping customers match colours between digital and analogue processes. Furthermore, upgradeability is built into HP Scitex HDR Printing Technology, helping customers protect their investment”, says Stephen Nigro, senior vice president GSB at HP.

Latex is popular

Following the hugely successful launch of Latex printers for the indoor applications HP  introduced a new super wide format version of Latex printers for outdoor applications. The new printer is called HP Latex 3000 printer. The water based alternative to solvent ink technologies enables now printing on heat-sensitive substrates via the new HP Latex Optimiser and a new ink solution that ensures consistent image quality at high speeds whereby curing is executed at lower temperatures than previous Latex-models from HP resulting in less energy intake. Productivity is given with 77 sqm/h for indoor and 120 sqm/h for outdoor applications.

introduced a new super wide format version of Latex printers for outdoor applications. The new printer is called HP Latex 3000 printer. The water based alternative to solvent ink technologies enables now printing on heat-sensitive substrates via the new HP Latex Optimiser and a new ink solution that ensures consistent image quality at high speeds whereby curing is executed at lower temperatures than previous Latex-models from HP resulting in less energy intake. Productivity is given with 77 sqm/h for indoor and 120 sqm/h for outdoor applications.

Mimaki brought the JV400 SUV to London. Available in two sizes (1300 and 1600 mm wide) it features Mimaki’s solvent UV technology and 4-colour printing resulting in a wide colour gamut, high glossiness and scratch resistance as well as good outdoor reliability. In addition the company introduced the new Mimaki LX101 inks for its JV400 LX series (again available in 1300 and 1600 mm width). The new inks feature orange and green Latex inks and combination with white Latex ink whereby a large colour gamut, deep black and glossy latex can be achieved. Mike Horsten, Marketing Manager Mimaki Europe points out that the new inks are an addition to the already existing LX 100 inks for the sign graphics market. The company sees the applications for the new inks in photography, proofing, sample design prints as well as in areas where high colour consistency is required. Updated products at the booth included the JFX500-2131 as well as the new UJV500-160, a large format printer that prints with UV-LED technology and achieves speeds of up to 100 sqm/h (4c) with LUS-150/LUS-200 inks. The machine can also accommodate white ink whereby speed is reduced to a maximum of 70 sqm/h. A new developed post-curing unit and vertical take up system enable stable media feeding and fully cured prints. Among the applications Mimaki showed at its booth was printing on cylindrical objects with UJF3042/UJF6042 as well as digital etching of nameplates and digital gold lacquer.

More speed, more functionalities

A new UV flatbed printer that features 14 pl drop size, a 3.2 x 1.6 m bed and speeds of up to 84 sqm/hr was shown by Dainippon Screen. The TruepressJet W3200 UV enables printing on substrates up to 50 mm thickness in six colours plus white (CMYK + LcLm, +LcLmWW or +WW). “After the introduction of the TruepressJet W1632UV featuring a speed of 94 sqm/h at drupa, Screen now introduces a second machine to the wide format market, therefore underlining its commitment”, says Mark Sherman, Area Director Middle East Africa region. “The printer represents a step change for the industry and incorporates the latest UV inkjet imaging technologies to deliver the ultimate in performance and reliability. Our customers want the assurance that they can produce consistent quality graphics, around the clock if need be, with a printer that delivers low total cost of ownership and the Truepress Jet W3200UV is the solution”, adds Brian Filler, President Screen Europe. Software options for the Truepress Jet W3200UV include the choice of Wasatch SoftRIP or ColorGATE Production Server 5, alongside Screen EQUIOS workflow automation and PDF Polisher file optimisation software to improve all round quality. The new press will be available from October onwards.

At Fujifilm’s booth the new Onset Q40i from Inca Digital could be seen. The flatbed press features a 10 pl drop, speeds up to 310 sqm/h and accommodates media up to 50 mm thickness. In addition the new Fujifilm Acuity Advance Select HS 5000 featuring six colour printing and speeds up to 49.7 sqm/h could be seen. Another premiere has been the Fujifilm Uvistar Pro8 that achieves speeds of more than 300 sqm/h and is designed for printing of display Pop and outdoor advertising projects on flexible and rigid substrates.

Austrian company Durst presented the latest addition to the Rho P10 series, the Rho P10 160 UV featuring the company’s Quadro Array 10M printhead technology resulting in speeds of up to 68 sqm/h and 1000 dpi. It enables continuous printing and parallel printing of boards whereby a roll-to-roll printing option and additional ink options (LC, LM, W, PCA-O+V) are available. In addition the machine accommodates double sided printing, fine art print quality for substrates up to 1.6 width. Enlarging the UV flatbed range of printers, the Rho 1012 and Rho 1030 were introduced. The first features a productivity of up to 490 sqm/ and 1000 dpi thereby making it ideal for backlits and close up viewed PoS applications. The Rho 130 reaches speeds up to 1,000 sqm/h thanks to its over 65,000 nozzles in the print carriage. In addition, auto loading and unloading tables cater to high productivity without much manual intervention. Both machines can be equipped with a roll-to-roll print option and automated roll-to-sheet-system. The new Rho IP engine for industrial screen printing applications and pad printing can be integrated into automated production lines and configured according to the desired application. It allows for up to 8 ink channels (CMYK, light colours, PCA, white or varnish) and is ideally suited for the production of membrane switches, instrument panels, dashboards, cover plates and small items that typically are printed by pad printing. Super-wide is the new Rho 512R, a roll-to-roll printer with Variodrop technology developed by Durst. It achieves speeds of up to 350 sqm/h and 900 dpi and can print three 1.6 m rolls together. Soft signage printers were impressed by the new Rhotex 322 that prints with water based dispersed dye inks up to 140 sqm/h and a resolution of 1200 dpi in 6 colours. Its greyscale printhead enables textile printing with drop sizes between 7 to 21 pl for home applications, wall coverings, domestic textiles, fashion and interior deign.

Several Product premiers

A soft signage printer plus an extended portfolio of products including the new Anapurna M3200 RTR, M2500, jeti TitanX, Ardeco and Asanti series has been introduced by Agfa.

Asanti is the new production and store front software from the company enabling end-to-end production workflows based on the popular Apogee product. With the new Anapurna M3200 RTR a mid to high end roll-to-roll UV-printer featuring a productivity of 116 sqm, width of 3.2, 6 colours and Konica Minolta printheads for indoor and outdoor applications entered the market. On the other hand new Ardeco large format printer combines sublimation capabilities with a accurate textile transport system. It comes in a choice of printhead configurations, and features an inline cold-knife cutting system. This fully-integrated digital textile solution is designed for volume production of all soft signage output including backlit displays, flags and general displays that benefit from being printed onto polyester based fabrics up to a maximum print width of 3.2m.

Xerox premiered the new wide format printer IJP2000 that has been previewed at GPP by Helios, its UAE distributor for this new Memjet powered system. Speeds are given with 420 sqm/h and resolution is 1,600 dpi on sheet or roll materials up to 1,060 mm wide and 190 g/sqm.

Canon launched the Océ Arizona 600s flatbed printer series that is designed to replace the Océ Arizona 550 series. Available from the end of July the printers can be optionally equipped with a roll-to-roll unit. The new models 660 GT and 640 GT feature a table size of 1.25 x 2.5 m while the XT models (640 XT and 660 XT) tables show a size of 2.5 x 3.05 m achieving a top speed of 64.7 sqm/h. Both 660 models offer six colour printing with six independent ink channels for CMYK plus additional cyan and magenta inks or while and varnish.

And there were others Maglev and Swiss Maglev are the names of IQDEMY’s latest UV printers that feature magnetic levitation, UV-LED curing, 6-colour printing plus white at 1440 dpi resolution and speeds of up to 110 m/h (Swiss Maglev) whereby substrates up to a size of 1450 x 2500 mm and 112 kg/sqm weight can be printed.

Maglev and Swiss Maglev are the names of IQDEMY’s latest UV printers that feature magnetic levitation, UV-LED curing, 6-colour printing plus white at 1440 dpi resolution and speeds of up to 110 m/h (Swiss Maglev) whereby substrates up to a size of 1450 x 2500 mm and 112 kg/sqm weight can be printed.

swissQprint launched 9 pl drop sizes on their Impala system that achieves a maximum speed of 140 sqm/h. The Nyala printer now features a new, reinforced roll-to-roll option that enables the 3.2 m wide large format printer to handle rolls up to 180 kg. In addition the company announced tandem print mode, a functionality that enables non-stop printing for all its three system (Oryx, Impala, and Nyala).

Seiko introduced the new ColorPainter M-64, a roll-to-roll printer that achieves speeds of up to 33.1 sqm/h on PVC while highest speeds are 66.5 sqm/h. A new low solvent SX ink covers the full range of the outdoor signage market. The company claims the new ink is almost odourless and shows smooth gradients.

Stunning effects can be produced with the new solvent based and UV curing Eckart metallic silver inks that are available for many printheads, among them Epson DX4, DX5 and DX6 for solvent and Xaar 1001 and Ricoh Gen4 for UV curing inks. In combination with CMYK printing “a whole new universe of metallic colours” can be explored without having to use expensive metallic substrates. The inks can be printed on paper, leather, vinyl and many other media at fast and economic print modes. “There is no requirement for a special printing machine or any special equipment”, says Silvia Pelke, Market Development Manager Digital Inks from Eckart. “All that is required is just a spot colour channel on the digital press. Our unique formula enables printing of metallics without clogging the printhead.”

Textile printing attracts more players

MTex introduced Turbo Sub, a high production digital solution direct-to-fabric sublimation printer with inbuilt fixation unit enabling speeds of up to 110 sqm/h and a resolution of 1200dpi. In addition the new MTEX 5032, a 3.2 m direct-to-fabric printer with integrated fixation unit for the dye sub market was launched. It features speeds of up to 58 sqm/h and 1440 dpi resolution whereby the company claims that this new printer shows vibrant colours and intense blacks.

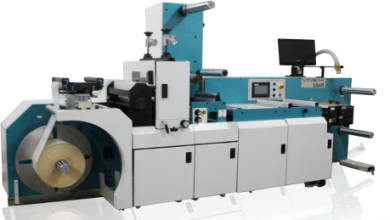

Italian manufacturer Reggiani introduced the digital transfer paper printing machine ReNOIR-Compact featuring a resolution of 2400 dpi, variable drop sizes starting at 7 pl, single pass inkjet printing on substrates up to 300 gsm and 1850 mm width and production speeds of up to 339 sqm/h. In addition, the ReNOIR-Compact digital printer for knitted, woven and non-woven substrates was shown.