BOBST Reflects on 2020 and Focuses on 2021 and Beyond

2020 will be remembered as unexpected and transformational. As we reach the end of it, we take time to look back at some of the important milestones that were achieved and key decisions that were made, and we reveal our expectations and predictions for the year ahead.

Throughout the pandemic, our key priorities have been caring for our employees, ensuring business continuity for our customers, and accelerating decisions to build a better future for all our customers. Adapting to the circumstances, we deployed live streaming demonstrations from our Competence Centers, providing an immersive experience to discover the latest printing and converting technologies. We also hosted several webinars during the year to keep our customers informed on our new solutions and share our industry experience.

Brand owners face increased competition and pressures around shorter times to market, smaller lots sizes, optimal protection and color consistency. These factors, along with the rise of smaller companies, associated with new business models including e-commerce, and the need to fulfil sustainability commitments, are leading the packaging industry into a profound transformation.

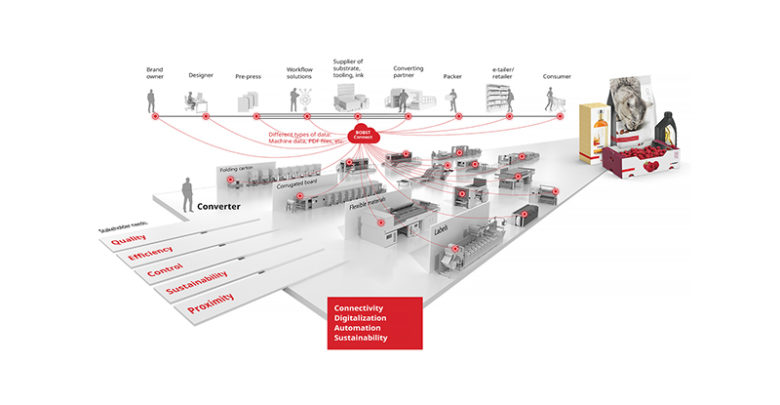

It is therefore an opportunity to drive more agility and sustainability. In spring 2020, BOBST announced a new industry vision aimed at connecting all packaging stakeholders throughout a new value chain to enable quality, efficiency, control, sustainability and proximity.

This vision, shaping the future of the packaging world, is based on four pillars: Connectivity, Digitalization, Automation and Sustainability. Within the vision we announced BOBST Connect, our software-based offering for digitalizing and connecting all products.

The vision is now becoming reality with new products & solutions and with a new company structure to be even more customer centric, less complex, and more agile, delivering more innovations. The new company structure can also rely on three new revamped industrial sites which will help our employees to enjoy better working conditions and our customers to come and see our innovations. The sites are San Giorgio in Italy for flexible packaging, Lyon in France for corrugated board and Itatiba in Brazil for our local production of folding carton solutions.

Folding Carton and Corrugated Board

In 2020, the folding carton and corrugated board industries were marked by an overall acceleration in e-commerce due to global online retail growth, where quality, waste reduction and goods protection are fundamentals. For folding carton, sustainability, increasing global regulation and demand for short runs and customization also grew in importance.

For folding carton, we launched two connected products: the die-cutter MASTERCUT 106 PER and TooLink, connecting tooling with the machine. Together, these solutions enable massive reductions in setup time & costs and increase profitability for unrivaled productivity. We launched the New ACCUCHECK – an in-line solution to inspect carton blanks for defects. In short, we made zero-fault packaging in folding carton a reality. We also launched the VISIONCUT 145 PER, the latest edition of large format flatbed die-cutter, which has been a huge sales success.

We launched MASTERSTAR, the world’s fastest, most automated, most versatile and most ergonomic sheet-to-sheet laminator, suitable for both folding carton and corrugated board. We celebrated 20 years since we launched POWER REGISTER – the ‘no contact’ sheet feeding system, which was an industry-first and remains unique in its capabilities today, demonstrating that true innovations can stand the test of time.

For corrugated, we hit a milestone with our VISIONCUT 1.6 flatbed die-cutter, selling our 300th machine. We continued to invest in our portfolio and made upgrades to our machines, including the EXPERTFOLD 145-165 folder-gluer range, which can now achieve a further 20% reduction in setup time and even greater flexibility and accuracy with corrugated packaging, and the FFG 924 NT RS, to which we added a dual slotter, enabling two boxes in one print repeat, significantly increasing flexibility and productivity to up to 40,000 boxes per hour.

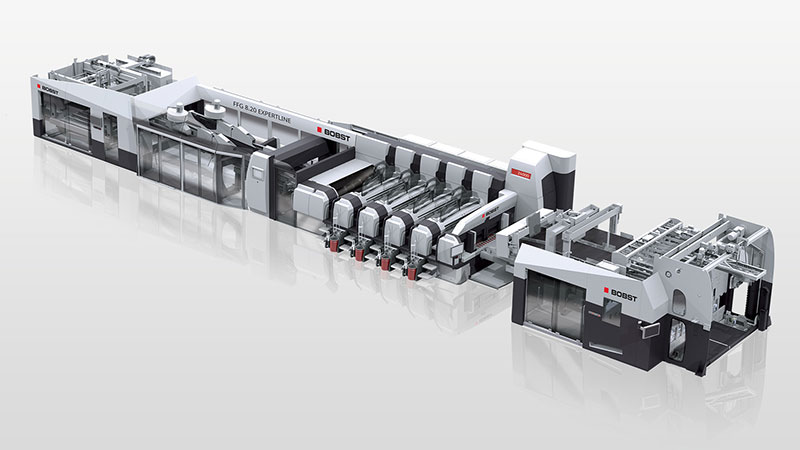

Within a market fueled by the e-commerce growth, the FFG 8.20 EXPERTLINE continued to be the best seller. We added the Fluid Folding feature to the FFG 8.20, increasing the folding quality and guaranteeing folding tolerances above standard specifications. For High-Graphics packaging production, 2020 saw the THQ FlexoCloud technology gain further traction within key clients. The Extended Color Gamut – oneECG solution, which is able to reach 95% of the color gamut – is helping converters to expand the flexo technology to new markets, leveraging their existing equipment, preserving their investments and bringing important sustainability benefits.

We continued our expansion in China, highlights of which included a key order for one FFG 8.20 DISCOVERY and two e-LINE die-cutters (designed and built in collaboration with Eterna) from Zhejiang Dashengda, one of China’s biggest manufacturers of corrugated and paperboard packaging. We also sold our first FFG 8.20 DISCOVERY in the UK – to a sheet-plant specialist called Manor Packaging, giving them a new level of automation that will bring a major competitive advantage in their market.

In 2021, we expect to see a continued increase of short production with higher value and premium packaging, meaning small volumes and cost efficiencies for converters, requiring greater automation. We expect significant growth in Asia, specifically China, propelled by increasing personal incomes and development of traditional retail and e-commerce products. From a product perspective, we believe that the SPEEDPACK, the revolutionary fully automatic corrugated-box packer that gently bundles boxes as they exit the folder-gluer, will become a new industry standard.

Labels and Flexible Packaging

Three key words best illustrate 2020: Digitalization, Automation and Sustainability

In labels, 2020 will be remembered as the opening of a new chapter for the industry. BOBST did not participate in the first chapter of the digitalization of label production, but is now leading the second chapter, combining high-quality, high productivity and low cost of ownership.

The Mouvent LB701-UV and LB702-UV, two label printers equipped with 6 colors plus white and capable of speeds of up to 100 linear meters a minute, now define the new standard. Aptech Graphics became the first company in the US market to benefit from this with its investment in the LB701-UV.

The BOBST MASTER DM5 is setting a new standard for the digitalization of the label industry. Prime, print, embellish, cut – all-in-one, all-inline, with digitally automated on-the-fly non-stop job change, an exceptionally high press uptime and outstanding repeatability regardless of the operator’s skills. This press has already been installed within four European customers, and recently received a European Digital Press Association (EDP) award, which honors the best technological developments each year.

Looking ahead to 2021, the digitalization will be the main driver for labels – all converters will seek for complete end-to-end digitalized solutions to optimize their production floor. All that can be digitalized will be, enabling converters to deliver faster, with better quality and less waste, answering the growing demand for on-demand labels production.

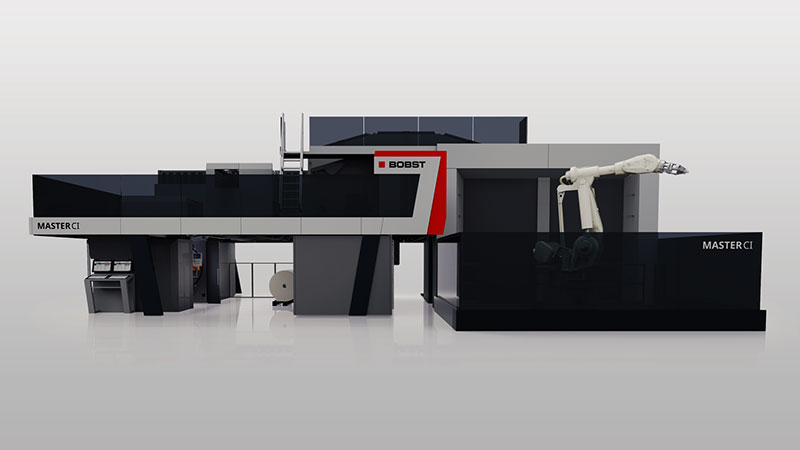

In flexible packaging, the new MASTER CI flexo press, which combines advanced technologies and smart systems enables the highest productivity, process stability and flexibility independent of the operator’s skill level. This machine optimizes the core BOBST pillars of Connectivity, Digitalization, Automation and Sustainability.

To master all the production steps for flexible packaging, we continued to lead the way in vacuum metallizing with barrier/sustainable applications, and established ourselves as number one in the Indian film market after Sparsh Industries utilized its new BOBST vacuum metallizer, an EXPERT K5 3300 mm with AluBond®, for an extremely successful entry into the Indian market.

We launched a revolutionary Extended Color Gamut management solution – oneECG – in rotogravure, bringing digitalization and more sustainability to gravure printing as well as allowing for shorter runs. Also in gravure printing, a tobacco packaging company invested in its third LEMANIC RIVIERA ILS, confirming this machine as a best in class solution for tobacco packaging with in-line printing and converting.

2020 also saw the launch of the NOVA SX 550 solventless laminator, which is a plug and play machine designed to deliver cost-effective performance for all production lengths on a wide range of substrates and thickness. It is very fast to install and easy to use for the operator. We delivered a NOVA SX 550 to a company in Argentina, confirming its ease of shipping and installation with the simple plug and play design, with remote assistance provided from BOBST.

In terms of coating, having previously announced new high barrier solutions, we continued to progress with our R&D projects for barrier coating applications on film and paper. We continued to collaborate with brand owners and material suppliers, testing and validating new solutions, leading to the sale of a new PVDC process coating machine to a customer in the US.

Looking forward to 2021, we foresee an acceleration at the converter level for sustainable solutions, leading to increased investments in printing and coating equipment – both vacuum and wet coating equipment. We strongly believe that plastic packaging, well produced and well recycled, has a future and we are committed to make it happen.

Services

In 2020, experiencing disruptions and limitations in terms of travel, the word services resonated differently, and high-quality remote services has never been more important. With Helpline Plus and Premium services, BOBST was able to provide support to customers remotely very effectively and making customer satisfaction a reality. Indeed, our NPS score, which measures our customers’ level of satisfaction for Bobst services, continued to grow in 2020 despite the challenging circumstances.

During April-September 2020, the number of remote sessions increased by 12% and the overall hours increased by 29% compared to the same period in 2019. In total, more than 40,000 hours of remote support has been provided to date this year. The increase is also an effect of more customers seeing the benefits of remote services, with the number of subscriptions to Helpline Plus and Premium increasing by 14%. Helpline Plus AR – the first ever remote assistance service in the packaging industry to incorporate a smart headset with augmented reality (AR) glasses – was of particular use for many customers who utilized the service to help train operators remotely during the restrictions.

In addition, because we are increasingly focusing on proximity to our customers, our local technicians were able to maintain a significant number of essential on-site interventions despite travel restrictions. We were also able to maintain our service rate on parts availability at an excellent level thanks to our good stock management policy and continuous communication with our parts providers.

In 2020, BOBST launched oneINSPECTION – a comprehensive quality control offering for all packaging industries. It is an integrated and evolving set of quality control solutions that proactively meet the needs of brand owners and converters, making zero-fault packaging a reality in the labels, flexible packaging, folding carton and corrugated board industries.

The Large Format Digital Inspection Table, optimized for large corrugated board sizes and one part of the oneINSPECTION offering, was launched just days before the major lockdowns in Europe. The first table was acquired by the Italian converter ICO, a company that sees digitalization as a clear competitive advantage. The Large Format Digital Inspection Table has recently won an EDP award, demonstrating its ability to efficiently and accurately manage the proofing of printed sheets and blanks.

Tooling continued to be a major focus, and the number of BOBST certified die-makers reached 17 in 2020, across four continents, despite the travel disruptions this year. In cooperation with CITO-SYSTEM, the tooling consumables manufacturer acquired in the beginning of 2020, we developed High Performance Tooling, which is setting new standards for tooling and facilitate the run of die-cutters at optimal speed as well as increasing box quality for converters. TooLink was launched, making the first step into the digitalization of tooling a reality. It connects the tool with the die-cutter and provides a quick set-up of the recipe in the machine, allowing a saving of up to 15 minutes with the changeover time for repeat jobs, saving valuable time in daily operations.

For 2021, we expect remote assistance to grow further. Quality control solutions will also gain in importance as the best way to reduce waste, reduce claims and increase profitability. The BOBST oneINSPECTION offering is part of the BOBST commitment to make zero-fault packaging a reality.

In summary

2020 was unexpected but it accelerated underlying trends and made decisions more obvious. It has confirmed that the industry vision we worked on is relevant and timely. Connectivity, Digitalization, Automation and Sustainability will be the four cornerstones shaping the future of the packaging world and we want to achieve this with meaningful innovations. In 2020, we celebrated our 130th anniversary with three fully revamped sites, and we deployed a new company structure with an entrepreneurial spirit to be closer to our customers.

2021 will ultimately not be very different from 2020. We will need to be resilient and at the same time we need to focus on what matters the most – meaningful innovations made to last. We will continue to deliver best in class machines and services, but with added intelligence and software capabilities to make packaging production better than ever. All our machines and new products to come will illustrate this commitment. You can count on us.