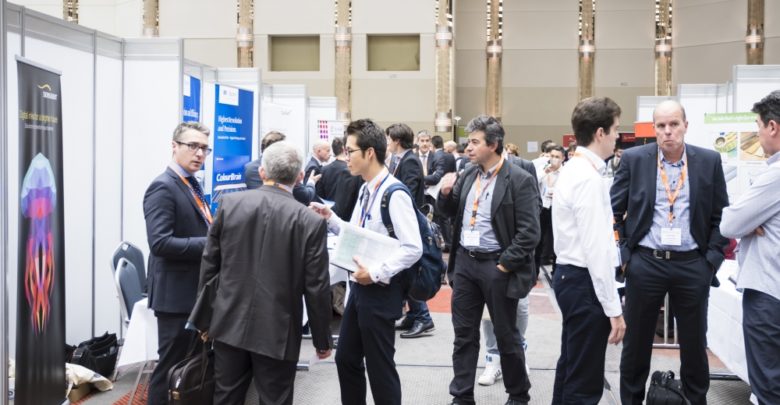

Already for the 5th time, the international inkjet community has come together at Crowne Plaza Hotel in Düsseldorf/Neuss. On 16-17th October 2018 over 500 engineers, chemists, researchers, innovators and C-level executives join The Inkjet Conference (TheIJC) to learn from 60 technical presentations, network at 90 tabletops and discuss future projects in industrial inkjet applications.

“After four events in Europe and the successful introduction of TheIJC in the USA earlier this year, we have been observing the constant global growth of inkjet. Our community expands as more and more manufacturing processes feel the impact of digital print technology and investigate implementing inkjet into their specific applications,” says Steve Knight from Digital Direct Technologies, co-founder of the conference.

Organised by ESMA (European Specialist Printing Manufacturers Association), with an ongoing support of drupa and in media partnership with “Specialist Printing Worldwide”, TheIJC has grown from 270 attendees in 2014 to 525 during last year’s edition. “Building this conference has been a dynamic process with a global approach to all those who are involved in hardware, chemistry, software and related developments. Each presenting company or research institute contributes to the high technical level of the conference programme and the invaluable social networking aspect. The role of TheIJC is to provide an optimal environment for creative exchange between experts from various fields, as well as to initiate and enhance business relationships,” says Peter Buttiens, CEO of ESMA.

The tabletop slots in TheIJC networking arena are filling quickly and several new players join the exhibition part every year. Atfex, BASF Personal Care & Nutrition, Cyan-Tec, DSM Coating Resins, Gardner Denver Thomas, Notion Systems, Siegwerk and Tiger Coatings are among those showcasing their products for the first time. Altogether 90 key industry players welcome visitors at their stands, including printhead manufacturers, ink producers, software designers, vision inspection experts, curing and drying companies, and leading research institutes.

Following the positive feedback from the previous edition, the conference programme opens with plenary sessions with state-of-the-art insights from all major printhead manufacturers. Afterwards, topics from hardware, software, vision systems, ink and curing, innovation and research are presented on three parallel tracks. The already confirmed titles include:

- “aNIR: Enabler for pre/post inkjet processing” by Dr Kai K.O.Bär, Adphos

- “Inkjet inks to colour your living space” by Dr Marc Graindourze, Agfa

- “UV LED boosters and waterborne UV resins: Latest resin solutions for next-generation inkjet inks” by Luc De Waele, Allnex

- “Powerdrop: Making ink stick” by Ben Brebner, Archipelago Technology

- “Adhesion of inkjet inks: pain or gain?” by Dr Yolanda Justo, ChemStream

- “2.5D-3D printing: New trends in digital surface creation with inkjet” by Thomas Kirschner, ColorGATE

- “Is this the end for spray coating?” by Clayton Sampson, Cyan Tec

- “Inkjet droplet measurement with laser diagnostics” Dr Hua Wang, Dantec Dynamics

- “Optimising the printing image: Analysis of the ink and substrate surface properties under inkjet conditions” by Dr Martin Grüßer, Dataphysics

- “The winning resin technology for inkjet in packaging” by Paul Hönen, DSM

- “Curing advantages with deep‐UV LED below 300nm” by Dr Tanja Bizjak-Bayer, Excelitas

- “Freedom to operate: Digital printing for textiles” by Jane List, Extract Information

- “Development of logic-based methodologies for quantitative and qualitative analysis of nozzle jetting and printhead performance” by Shane O’Neill, Fujifilm Dimatix

- “Key success factors for developing and commercialising a successful aqueous inkjet product: A specialist point of view vs. a generalist perspective.” by Dr Hamid M. Shirazi, Fujifilm Inkjet Technology

- “Handling inks in inkjet systems: Main requirements for liquid pumps” by Markus Orlando, Gardner Denver Thomas

- “High speed and high quality with variable data: Inkjet’s Holy Grail” by Tom Mooney, Global Graphics Software

- “Direct to shape printing of complex objects” by Phil Collins, Global Inkjet Systems

- “Understanding UV LED lifetime” by Dr Matthias Sachsenhauser, Hammamatsu

- “Key success factors for inkjet integration projects” by Steffen Orth, Hapa

- “Physical analysis of ink-radiation interaction in drying processes” by Dr Larisa von Riewel, Heraeus Noblelight

- “Inkjet analysis by light scattering in the printing gap” by Florian Bourguet, iPrint

- “Mapping printhead jetting possibilities with dynamic ink properties” by Dr Mathieu Soutrenon, iPrint

- “Prediction of open nozzle times for volatile inks by meniscus motion analysis” by Johannes Renner, iPrint

- “Designing pumps into ink supply systems” by Andreas Hauri, KNF

- “First experimental study using a novel device for characterising drop formation, drop substrate interaction, and waveform optimisation” by Dr Thomas Willers, Krüss

- “Peeling the inkjet onion: Nozzle out detection and compensation” by Jonathan Wilson, Meteor Inkjet

- “How to evaluate your filtration and degassing processes for your digital inkjet ink” by Michael Mehler, Pall

- “Breakthrough technologies for maximised UV LED output consistency and control” by Dirk Exner, Phoseon

- “Industrial print system design” by Florian Fässler, Polytype

- “Filtration and particle size analysis: Why these techniques must be utilised together” by Larry Unger, PSS/Soliton

- “Edible inks and printing on pills” by Dr Simon Daplyn, Sensient

- “Inkjet inks for labels and packaging” by Matthieu Carni, Siegwerk

- “Future strategies for energy curing ink design” by Damian Ward, Sun Chemical

- “Possibilities of digital printing for exterior and interior architectural applications” by Dr Dieter Holzinger, Tiger Coatings

- “Latest advances in Silicon MEMS printhead technologies” by Jason Remnant, Xaar