Canon’s Sustainability Drive Gets Quocirca Recognition

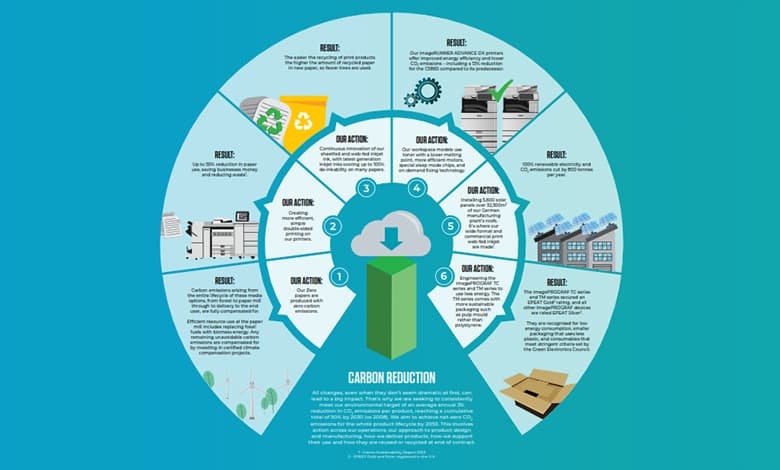

Canon Europe has once again been named a leader in Quocirca’s Sustainability Leaders report, an annual market analysis which evaluates steps taken by print vendors to lower their carbon emissions. The 2024 report recognised Canon for its robust sustainability vision and strategy, underpinned by its priorities to improve environmental performance across its portfolio of products and services.

Quocirca’s report highlights the wealth of initiatives put in place by Canon to advance its sustainability efforts. These include commitment to remanufactured and refurbished products, the use of renewable energy across global production sites, and ongoing development of more sustainably designed technologies.

Several initiatives contributed to Canon being recognised as a market leader in Quocirca’s report.

Advanced Recycling and Remanufacturing

Support for the circular economy forms a significant part of Canon’s sustainability strategy with the organisation recycling parts and hardware where possible for a second life. Canon remanufactures its flagship imageRUNNER ADVANCE ES range at its dedicated factory in Giessen, Germany, where it rebuilds devices using at least 90% reused parts. Canon also refurbishes multifunction devices for sale across Europe, through its Certified Used (CU) programme, which guarantees stringent levels of performance and reliability.

Canon also has long-established closed-loop recycling programmes, such as its global toner cartridge-recycling initiative, which has been running since 1990, and has achieved a cumulative reduction of new resources of approximately 3,31,000 tonnes.

Sustainable Design

The technology giant is also committed to sustainable product design with a focus on creating energy efficient and long-lasting devices. Canon’s imageRUNNER ADVANCE DX C3900 multifunction printer is built with longer life parts and uses low temperature fixing toner to help organisations reduce power consumption. Another example is the recently launched imageFORCE C7165 multifunction printer, which is built with 30% recycled plastic and features Canon’s machine learning technology to help predict maintenance needs and reduce the need for in-person diagnostics.

Solutions and Services to Support Sustainability

Canon has a comprehensive portfolio of solutions and services to support sustainability. Its Climate Project Contribution Service, for instance, enables customers to compensate greenhouse gas (GHG) emissions that arise when using a Canon product, by investing in projects that reduce the same amount of GHGs in a different place. Further, while Canon’s Discovery Assessment Service helps businesses review impacts related to print and scan infrastructure and identify areas for improvement, its Digital Transformation Services support customers with digitalisation processes through a suite of solutions.

Separately, Canon’s strong brand perception for sustainability was highlighted in Quocirca’s Brand Perception Report 2024, which found that over a third (38%) of respondents viewed Canon as a strong sustainability brand.

Hiro Imamura, Executive Vice President at Canon EMEA, comments, “Sustainability continues to be vitally important for both Canon, and its customers and partners, and we are proud of the numerous initiatives and partnerships that we have in place to help drive positive impact on the environment and society. We are delighted that our significant efforts have been recognised in Quocirca’s report as we continue to accelerate our actions in line with the UN’s Sustainable Development Goals.”

.gif)