PRATI Launches DIGIFASTone Digital Finishing Line

It is the new modular line of digital finishing based on the “FUTURA by Prati” DIGIFASTone technology, With laser die cutting units and customized digital finishing groups such as tactile effects and textures, decorations and textures up to 130 μm, Braille and Marburg Medium printing for pharmaceutical products. A very high performance line, for the new generation of label finishing solutions in line with the requirements of Industry 4.0.

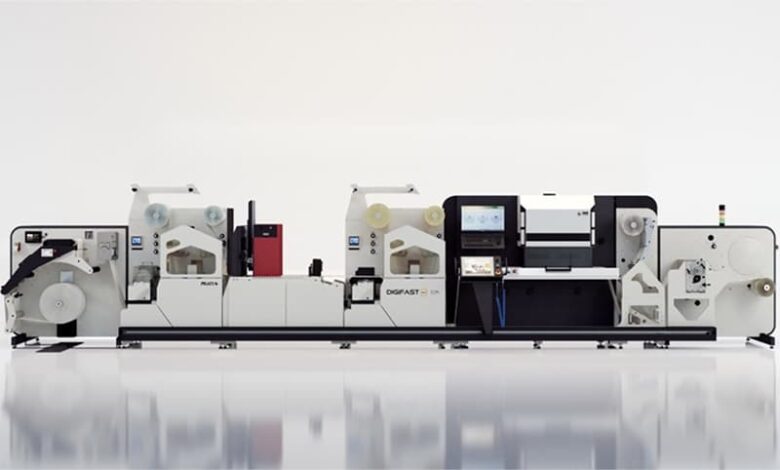

The new high-performance PRATI digital finishing line, DIGIFASTone, is completely modular and available in S-D or D-S configurations, now also allows the installation of laser die-cutting and digital finishing units depending on the needs. They are lines based on the “FUTURA by Prati” technology that defines the standard of the new generation of finishing solutions in line with the needs of industry 4.0. In this article we describe its features and highlight its advantages for the converter.

Ultra-fast job delivery times and on-the-fly job change with speeds up to 100 m / min, through automatic Barcode / QR-Code reading, are among the most obvious advantages of DIGIFASTone laser die-cutting, based on a technology that responds to the just-in-time question.

Added to this is the possibility of an entirely digital finishing thanks to DOD LED / UV print heads. With a speed of 50 m / min the possibility of selective UV coating even at high thickness. In addition, the complete version is already available with the application of foil for an entirely digital “cold gold” and “hot gold” effect.

Contrary to what one might think, this printing technique allows a limited investment and reduces processing costs. With this new technology from PRATI, narrow web label and packaging converters can therefore obtain digital finishing, with the possibility of creating high quality ennobled products even in short runs. DIGIFASTone is easily managed by a single operator. This is due to perfect ergonomics and a high level of automation.

The DIGIFASTone line in detail

The unlimited and immediate upgrade possibilities allow you to protect the initial investment and adapt to any market context thanks to the basic technology “FUTURA by Prati” for finishing solutions in line with the needs of the new generation 4.0 industry.

The technological innovation developed positively improves the life of the converters: it simplifies the work of the operators and increases their safety; it also increases the margins for the entrepreneur and whats more it offers the brand a perfect product.

The renewed DIGIFASTone finishing line stands out for its precision and modularity and is appreciated for its speed, versatility and ergonomics.

Conceived with a high level of automation and intuitive controls, DIGIFASTone, in it’s basic configuration, can print, die-cut, strip, count, slit and rewind while being able to upgrade with additional units for more advanced operations.

In S-D or D-S configurations, it can handle a wide variety of materials: self-adhesive, clear-on-clear labels (including AD-MDO and UPM PP30), wrap-around labels, shrink sleeves, plastic films, unsupported paper and plastic materials , in a range of thicknesses from 12 to 350 microns.

Built with an open platform and in line in Industry 4.0 mode, DIGIFASTone generates a very small amount of waste material, significantly reduces set-up times and boasts a register accuracy of 0.15 mm, even reaching 100 m / min in the configuration with laser die cutting. All these pluses exceed current standards and make DIGIFASTone the ideal investment even for limited editions.

Accessories and finishing processes

DIGIFASTone is available with various accessories to be able to perform a wide range of finishing:

- buffer for connection to a digital printing machine;

- both rotary and semi-rotary flexographic unit for total and spot coating;

- printing and digital finishing;

- cold foiling;

- rotary and semi-rotary die-cutting in register on pre printed material; laser die-cutting;

- hot foiling and embossing;

- digital screen printing;

- control module for 100% inspection of print quality;

- longitudinal cutting systems with manual and automatic blade positioning;

- single, double and turret rewinding.

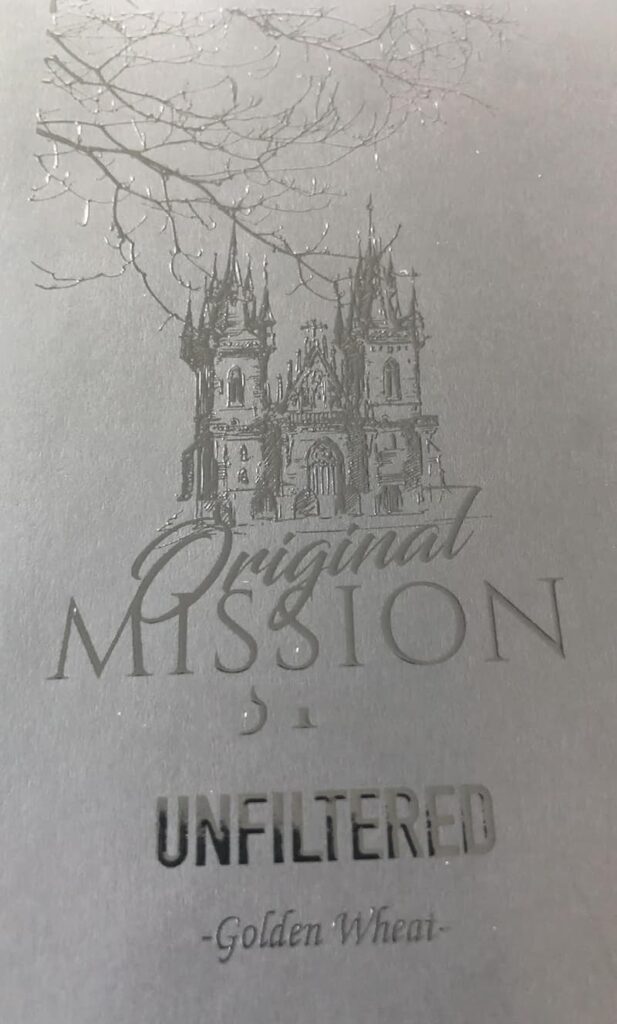

Digital ennobling

The digital finishing unit, essential for obtaining high levels of productivity, can be built with a single print head, for ink thicknesses up to 250 microns at a speed of 25 m / min, or with a double print head, for thicknesses up to 280. microns at a speed of 50 m / min.

These are its many advantages:

- deposit speed higher than 320 m / min

- tactile effects and textures, without the need for embossing plates or thick supports

- decorations and textures up to 130 μm with Xaar 2002 GS12 HL

- One-step Braille printing

- Marburg Medium font for pharmaceutical products

- line speed up to 50 m / min from 2 Xaar 2002 GS12 HL heads in series.

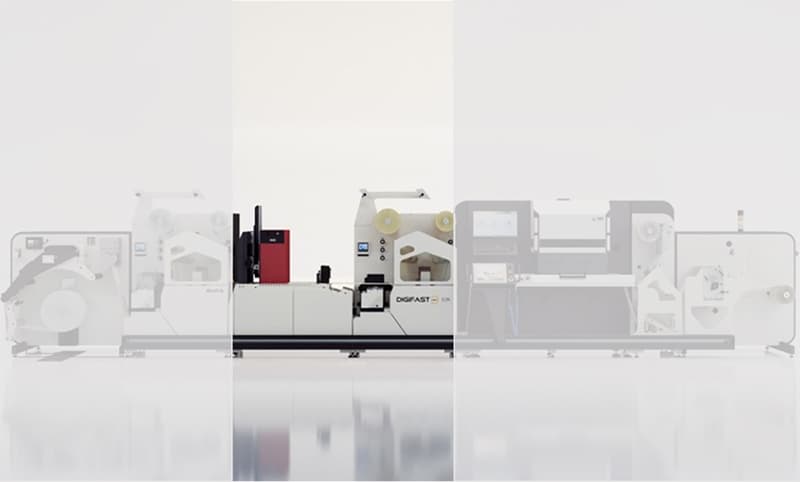

Laser die cutting

The DIGIFASTone Laser module is able to process the entire workflow completely digitally from the PDF file to the shipment, guaranteeing a unique workflow for a truly digital model: web-to-labeling, web-to-sticker, web- to-packaging.

Among the advantages of using DIGIFASTone Prati with the optional Laser is the ultra-fast delivery times and high productivity thanks to a job change through automatic Barcode / QR-Code reading. In addition, the laser can process detailed die-cut shapes, without any contact with the substrates, works on strong adhesives and does not damage the liner and has no limits in the length of the label. And, above all, laser die-cutting ensures a completely digital workflow from design to delivery, for an extremely efficient and truly digital business model: from the web to labeling and from the web to packaging.