IPEX 2014

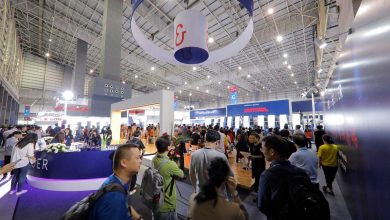

Ipex exhibition recently closed its doors and ME Printer’s technical editor Rod Hayes who was at the show from day one believes Ipex 2014 in many ways was much better than expected.

Here’s what he has to say about the show:

Ipex is now over, are there any lessons to be learnt from its staging? Almost certainly, but what form the lessons take and on whom they will impact is open to considerable speculation.

Ipex has always been part of a smallish pantheon of printing exhibitions having a global impact; Drupa is undoubtedly the leader, with the Print event in Chicago, also having a claim to influence beyond its national borders. Almost all others are regional in their reach and effectiveness.

Yet any trade show has an important community role to play and the role Ipex 2014 had more in common with a bunny trapped in the headlights of an oncoming car: trade shows need something to change – and fast.

Any print and graphic art exhibition in the future cannot expect to succeed and be profitable for its organisers, if the format is similar to past events. To give credit where it’s due, Informa, the Ipex parent company recognised change was required and rolled out a series of master classes, work-shops and other supporting technical events designed to complement exhibitors’ offerings. On one hand the show was well received and supported by close on 25,000 visitors, with around one third of visitors coming from the Middle East and Africa. This suggests Ipex fulfilled its global reach. On the other hand the numbers visiting were nothing like those of yesteryear.

Any print and graphic art exhibition in the future cannot expect to succeed and be profitable for its organisers, if the format is similar to past events. To give credit where it’s due, Informa, the Ipex parent company recognised change was required and rolled out a series of master classes, work-shops and other supporting technical events designed to complement exhibitors’ offerings. On one hand the show was well received and supported by close on 25,000 visitors, with around one third of visitors coming from the Middle East and Africa. This suggests Ipex fulfilled its global reach. On the other hand the numbers visiting were nothing like those of yesteryear.

Not one for one minute would you say the printing industry is like it was in the days when fierce competition raged over who had the fastest press, the quickest make-ready and the easiest plate making system. Today the issues that confront the graphic arts industry are winning print orders, providing multimedia support and empowering customers to be more profitable.

It is clear that certain technologies in the printing industry have now matured to a level where any further increments of performance can only be obtained by fearsome levels of capital investment. What is also clear many technologies are being superseded by methodology coming out of left field. Henry Ford, the American motoring pioneer’s dictum has come to pass in the printing industry. When he was talking about how origins of the model T Ford, he was quoted as saying along the lines of: “If you asked a focus group what was required then, it would have come up with a faster horse”

In the same vein, the Stone Age didn’t end because people ran out of stones, yet its clear trade shows of any kind will have to follow a new trail of innovation Ipex has tried to pioneer. For all the enjoyment a visitor would have had visiting Ipex, seeing old colleagues, meeting new ones there was a pervading atmosphere of analysing how to chisel ever finer stones and getting horses to run even faster.

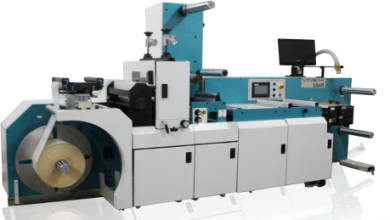

The plethora of digital finishing systems is an excellent case in point; there was a time when Wat-kiss, Morgana, Duplo and Horizon had this market to themselves, this Ipex there was a flood of machines from around the world whose only requirement was to be able to plug in to a 240 volt socket and they would fold, cut, perforate, stack, slice, box, number and overprint almost any stock at upwards from one to 3,000+ sheets an hour.

Hans Gronhi the Japanese/Chinese press manufacturer had a superb stand showing off its high quality range of B3 and B2 offset presses; it would be wrong to say it was a victim of a ho-hum atti-tude by visitors, but high quality presses of this kind can now be viewed on display in any regional centre such as Dubai and Doha. This doesn’t lessen the quality of the machine or its productivity, but it does say something about trade shows.

There was another aspect that Ipex highlighted and other trade show presenters will have to wrestle with; this is the increasing numbers of manufacturers and suppliers, mainly from China, but not ex-clusively so, who are seeking agencies for a range of what could only be described as mercantile sundries: laminating film, PVA glue, stitching wire and the likes. Nothing wrong with that – it’s a free world everyone has the right to a voice, but at Ipex these small booths were scattered around the show like peanut sellers in a bazaar, usually a single individual sitting in a booth with graphics offer-ing no real information as to why he or she was there and scarcely enough English to explain their point. It has become tradition for used machinery agencies to have their own sector, informative and well laid out it was too, surely those with a limited range of products should also have their own sector, rather than be scattered like chaff throughout the show.

Environmental solutions

The real question that show operators like Drupa and Ipex should ask of their exhibitors: “To whom are you targeting your wares?” A manufacturer of laminating film from China is seeking an agent for his products – he has little interest in the end user. Contrast such exhibitors with two new com-ers to Ipex. The first is Enviro Image Solutions of Vancouver Canada. This company is offering a service in which a sheetfed printer does not buy any new blankets, but is supplied with a quantity of blankets that are refurbished using a unique approach by Enviro Image. As the blankets near the end of their useful cycle, they are replaced with freshly refurbished ones and the used ones are re-turned to Enviro Image on a managed cycle for repurposing. The cost to the printer is around 50% of a new one, the saving to the environment is quantifiable and significant (The carcass for exam-ple is rarely damaged during use). In addition Enviro Image can quickly establish how efficiently the printer is using both his blankets and how well his press is set up. It seems like a win to everyone involved. Such a service benefits the printer.

There were others as well: Metafix, another Canadian company from Montreal. It sets out to ser-vice printers in three ways: the first is a monitoring system for fount solutions which provides doc-umentary printouts of the performance parameters of the printer’s system in real time on how the fount is performing – ph levels temperature etc. Subtle variations in fount is a major culprit in print variability. This is done using sensor connected to the Internet. The second is for CTP and relates to silver recovery and extending the life of CTP chemicals. The third service is advisory, helping printers to operate in and environmentally efficient manner. Here again is an innovative way of sell-ing the service; the monitoring equipment is supplied without charge, costs are born by a monthly service charge. A printer is in an ideal position to see assess benefits.

There were others as well: Metafix, another Canadian company from Montreal. It sets out to ser-vice printers in three ways: the first is a monitoring system for fount solutions which provides doc-umentary printouts of the performance parameters of the printer’s system in real time on how the fount is performing – ph levels temperature etc. Subtle variations in fount is a major culprit in print variability. This is done using sensor connected to the Internet. The second is for CTP and relates to silver recovery and extending the life of CTP chemicals. The third service is advisory, helping printers to operate in and environmentally efficient manner. Here again is an innovative way of sell-ing the service; the monitoring equipment is supplied without charge, costs are born by a monthly service charge. A printer is in an ideal position to see assess benefits.

It is clear from these two examples a service was being offered which is innovative and capable of offering far more than cheap consumables, all of which suggests that exhibitors should be placed in zones that better reflect where they sit relative to the market as a whole entity.

Drupa will be the next ‘world type’ show in the firing line; the case for manufacturers to haul from around the world and install major printing presses there is fading by the hour. Thanks to the multi-media communications set ups pioneered and developed by printers, almost any potential customer of for a printing press can be identified and contacted constantly; any printer contemplating a major capital investment will be wooed almost unmercifully and he will be able to weigh up, test and ex-amine the pros and cons of the investment down to the most microscopic detail virtually without leaving his seat.

A Different World, A Different Industry

Circumstances have now changed since Drupa 2000, when over 400,000 visitors attended. It seems now unbelievable that a prospective investor would go to go to such a show as Drupa 2000 today, merely to explore and compare competing machinery for future investment. The awareness would come long before he got there that he would only be going to the show to look for a faster horse. Today he is more likely to be embarking on a totally different investment strategy.

There is a good reason behind this line of thinking and it is this; it is not only the way print is being produced that has changed, the very way the industry is being managed has under gone a revolu-tion. Rupert Murdoch at London’s Wapping was an early catalyst for change: ‘The Times’ was one of the first of the major newspapers to be produced using what we would consider as modern CTP with workflows linked to highly automated machinery. The revolution though perhaps begun there, didn’t stop there. We now have the current situation where increasingly, the owner/manager of a dynamic printing business, is no longer is an ex printer who started off with a cheap second hand press in someone’s back yard, but more likely to have a degree; employ a chief financial officer (CFO) and analyses every cent of income and expenditure.

This is why Ipex only attracted the numbers it did, and why Drupa is certain to face the same angst in 2016. Modern managers would set up training courses on his own premises or at a supplier’s venue where appropriate, the manufacturers would of course be offering such training opportunities constantly, the idea of a Masterclass at an exhibition was a good one for Ipex to try and it was well attended, but surely it still ranks in the stone sharpening category.