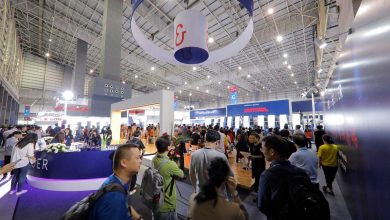

ME Printer Stand At SGI 2014

ME printer stand at SGI has always been a meeting place for industry players and ME Printer team of journalists and colleagues who come from different countries. This year was no exception. ME Printer’s booth was abuzz with activities. Other than attending guests and visitors our team was busy throughout the event preparing Daily Printer, SGI’s official newsletter. Fresh news and updates were gathered each day from exhibition floor only to be included in each edition.

Our contributing editor Dr. Nicholas Hellmuth from US and Sabine Slaughter from Germany were also involved actively in preparing news, views and interviews during 3 day event. It’s always refreshing to see familiar faces during exhibitions and interact with the players who shape regional printing industry one way or another. The diversity of the visitors to ME Printer booth was also amazing and it reaffirms the reach and impact of our magazine across the region and beyond.

What was more interesting was the demand for information about the printing industry in the region and the possibilities that it can offer to the investors and manufacturers around the world. Every exhibition reminds us how valuable information is to people involved in the world of ink and paper and how important is to gather and prepare these information to keep the industry informed.