Koenig & Bauer Relocates Flexotecnica

The P24x efficiency programme adopted by Koenig & Bauer in September 2020 to strengthen our market positioning and boost operating profitability made further progress in its implementation. One of the areas of action is the optimisation of production and assembly plants. Koenig & Bauer is consistently pursuing this path through internal Group bundling, relocation and realignment in order to remain competitive in the long term.

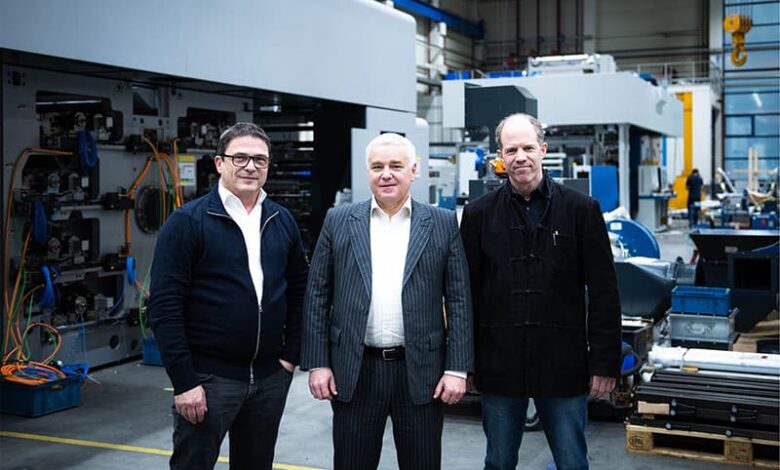

This includes the relocation of Koenig & Bauer Flexotecnica’s assembly operations in Tavazzano, Italy, to Würzburg. Board spokesman Dr Andreas Pleßke assures: “We have carefully examined all options to preserve as many jobs as possible in Tavazzano. Responsibility for the entire site makes the relocation of assembly unavoidable. Bundling assembly within the group makes the site more efficient and profitable and thus secures jobs in the long term. Core functions such as construction and development, service and sales for Italy will be retained and also strengthened as required.”

“In Tavazzano we will continue to lead the group’s work on innovative, functional flexo printing solutions. Customers can continue to rely on our many years of expertise in the field of flexible packaging,” explains Luigi Magliocchi, managing director of Koenig & Bauer Flexotecnica.

The Covid pandemic in particular has seen increased demand for film-wrapped foodstuffs, and rising e-commerce trade is also calling for weight-saving, flexible packaging. The advanced CI flexo presses for printing on paper, film and other flexible packaging materials are part of Koenig & Bauer’s broad product portfolio, which makes it the only press manufacturer to master all industrial printing processes on virtually all substrates. This is why research and development expenditure remains untouched.

Board member Christoph Müller adds: “In the coming years Flexotecnica’s focus will be on using Koenig & Bauer’s strong service network with over 1,000 employees and global sales to further expand market share in the flexible packaging sector and to continue to be a partner at eye level for our customers with innovative, customer-oriented solutions and digital services. The cooperation between the various business units at Koenig & Bauer has already proven its worth.”

As part of the P24x efficiency programme the company has launched a number of initiatives ranging from the further development of the press range in line with market needs, the digitalisation of processes and the reduction of manufacturing costs. Koenig & Bauer is thus continuing to focus on end-to-end system solutions and optimising the total cost of ownership (TCO) for customers. Bundling assembly and closer collaboration, e.g. in engineering and service, will generate synergy effects throughout the value-added process and across the entire portfolio. The creation of competence centres facilitates more efficient structures, which in turn provide scope for more innovations, customised solutions for customers and ensure Koenig & Bauer’s customary premium quality.