“DTG is Where Fashion and Inkjet Technology Finally Meet”

An Exclusive interview with Ayman Omar, Brother’s Area sales manager

Brother is a household name, mainly because of its swing machines, which you could find in many houses across the world, so for the company to enter direct to garment printing business seems very organic and natural. Brother Group began by offering repair services for sewing machines in 1908. Inheriting the DNA of the founders, the Yasui brothers, have continued providing a variety of products that meet the changing needs of customers for over 100 years.

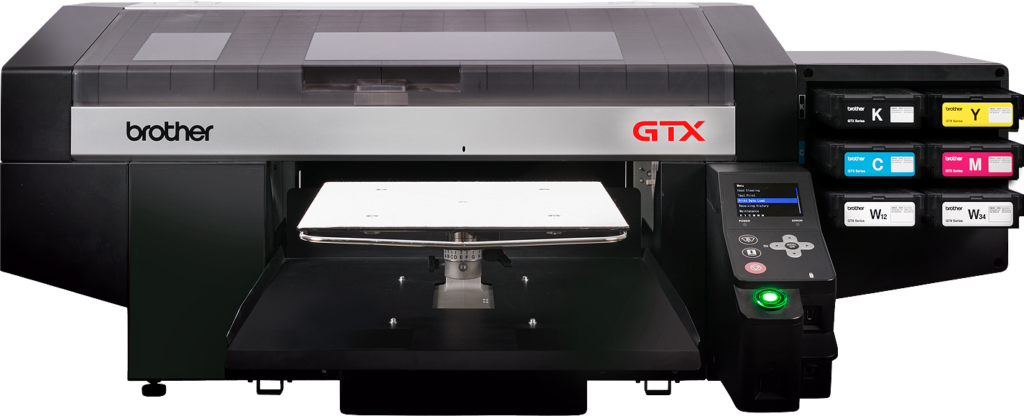

Following a series of innovative products including laser printers, fax machines, type writers and other products the company introduced the garment printer “GT-541 in 2005 in the US. It was inspired by T-shirt culture in America. The new printer was manufactured by applying the inkjet technology and combined technologies of mechatronics and special ink. Being able to quickly print pictures from the computer onto fabric with no specialized knowledge, the printer was loved by Americans, who have long had a culture of creating original T-shirts.

To find out more about Brother Group and its activities in our region we sat down with Ayman Omar, Brother’s area sales manager.

Brother has launched a new method for DTG (Direct to Garment) printing of polyester materials, is this method environmentally friendly and is it available in our region?

It’s in our DNA to search and invent solutions that help our customers increases their products portfolio and enjoy a successful business. One of the successful products which we’ve introduced lately to the market is printing on pure colored polyester. Printing directly with a digital solution on colored polyester has been a challenge for many manufacturers. We are delighted today to inform all our customers that yes, it’s possible with your same Brother printer (GTX, GTXpro, GTXpro BULK), with your same inks and your same pretreatment, print on pure polyester. We didn’t have to change any of our consumables or machines to reach a great result and washability on some polyester materials we tested. The only difference is the process of printing. So today you can use your GTX to print on cotton and polyester. The fact that all our consumables are water based and certified with the Oekotex passport. Is a testament that our consumables are environmentally friendly.

Brother Launched GTXpro DTG printer back in August and prior to that the company introduced GTXpro BULK, how did markets in our region reacted to these new products?

Since the success of the GT3 followed by the success of the GTX, our customers started to follow our latest trends and products. And now we are enjoying an extraordinary reputation in the global market in general and in the Gulf territory in particular. Since the introduction of the GTXpro, we’ve received a lot of attention from our customers in the Gulf, and this attention is growing every day. Because of internet and the social media, customers from the Gulf area could read or see a lot of positive feedback from our customers in Europe or the USA, and they were inspired by many of them.

GTXpro BULK hasn’t find a foothold in this market yet, mainly because it is designed for highly industrial productive environment. It will eventually find its place in the Gulf market as well.

Who are the customers of these DTG printers? Sign shops, commercial printers, digital printers…?

We have the GTXpro which is serving customers in stores, kiosks, online stores, print houses, event’s organizers premise, tourism sector, malls, screen printing houses, airports, fashion designers and many more creative businesses.

GTXpro BULK is suitable for printing large volumes and targets screen printers, garment producers and the large online shops.

What is your advice for someone who wants to enter DTG market for the first time?

Retail and fashion are the strongest sectors in the Gulf area, so placing a GTXpro in a retail store or a small kiosk and at the same time establishing an online store or a Facebook page to customize garments should be a successful business venture. Direct to garment printers are so flexible and gives you the chance to express your creativity and style in business. Our partners in the region will work side by side to support you, so with the correct equipment, ideal store location (in case of retails) and a strong marketing, you should be able to run a fruitful business with a reasonable investment.

How many installations you have in the region?

We believe that we are leading the market in the region. Thanks to our reliable products and the professional partners, our reputation is growing day by day. We installed around 140 GT machines in the last 3 years in the Gulf region.

However, I think we are not there yet. We are aiming at a greater success such as the one we are enjoying in the European or American markets.

Brother says the ink used in their machines are environmentally friendly, in which way? Are they recyclable, can they be deinked from the garment?

The definition “Environmentally friendly” can be seen from different aspects. Our inks are water-based inks, which are generally more environmentally friendly than plastisol inks or some solvent inks. In addition, we tested our consumables by an independent lab to check the VOC emissions during operation and we received the confirmation that the amount of all chemicals used in our inks is lower than the limits stipulated in environmental regulations of the EU. Our inks are also vegan; no animal have been harmed to produce these inks.

How did Coronavirus affect your activities and what measures did you take to mitigate the crisis?

As anyone else in our international society, we are sad to witness the great loss of human lives across the globe caused by this devastating pandemic. We took (as Brother) an immediate responsible step to reduce or prevent any additional damages. We’ve decided to cancel any traveling activities and replaced all our meetings, trainings and exhibitions with the online solutions. We’ve helped at the very beginning by producing and delivering masks to charities, in a time when there was a severe shortage of masks. As far as our business is concerned our sales activities have been booming, mainly because of our online businesses. These days our customers who own online stores are more successful than ever.

8-Maybe I am old fashioned but Brother in our region has always been famous for its swing machines, do you believe the brand now has effectively established itself as a major DTG supplier in our region?

Brother is a 110 years old organization. The world knew us from our fine sewing machines. The garment industry most of the time opts for Brother when they need quality and reliability. We launch our new DTG products with the same spirits and the same passion that is the hallmark of Brother throughout its history. We were one of the first manufacturers to introduce DTG in 2005. We’ve been working together with our engineers, partners and customers to lift the direct to garment technology position to where it’s now.

Our customers in the region are very satisfied with our products and services. I can tell you many successful stories, thanks to the products and partners who carry out “Brother at Your Side” philosophy.

Can you explain a little bit about the history of Brother in our region, when did they enter our markets and how their business evolved during past years?

In 2007 we’ve entered the Gulf region for the first time with our Garment printer. But Brother has been active in Gulf area since long time ago, selling and servicing other range of products. We have been working together with our local partners in the region to promote, sell and support our direct to garment solutions. Today you can see our GT3, GTX or GTXpro in malls, airports, print and fashion houses, and many more outlets.

How important is Gulf markets for Brother and why?

The Gulf market is a unique market and very important to us. It’s a very colorful market, where we see many opportunities. People in the Gulf are mostly business oriented and filled with innovative ideas. Sometimes when I’m visiting cities such as Dubai in the UAE or Riyadh in KSA, it amazes me how fast developments can be implemented! We also see a promising industrial future in the textile sector, pushed and motivated by the governments, and that will transform the whole region into a very attractive market to invest in.

E commerce and online shopping is experiencing an unparalleled growth in our region, mostly due to Covid-19, do you see this as an opportunity for DTG?

We are experiencing that already. Our customers from the online sector have extended their productions by purchasing more machines from us to cover growing demand from their customers. We’ve witnessed many newborn online businesses who jumped on opportunities at the right moment. I do strongly advice people in the Gulf region to jump on the online store’s bandwagon. Ones you have an online store, you don’t sell your product in your city only, you will have no boarders, you establish a better platform, you will have more success and your business will grow.

Last but not least tell us about yourself and your experience in the world of graphic arts?

I’m taking care of Brother Industrial printer’s businesses in the Middle East and North Africa. When I was searching for a new challenge, it was very important for me to work for an organization where I can believe in their products. Brother is a fine company with a great attractive product, which makes it easy for me to tell a truthful story to my customers.

I’m in the printing industry since 1999, I have witnessed how the Inkjet technology and its footprint on the Graphic arts have been increased through the years. And today I am proud to say that I could always have the chance in helping these extraordinary developments, starting from the large format printers, solvent, UV, water base inks. I’ve been concentrating in setting the ICC color profiling to help artists and machines’ manufacturers to get from their printers exactly what they see on their monitors. In order to have the exact color, you have to have knowledge in inks, substrates and graphic designing. After these long years moving from one manufacturer to another, gaining more experiences, I’ve chosen to join Brother and move on with the DTG, where fashion and inkjet technology could finally meet.

12 Comments