A Visit To Canon Facility In Poing

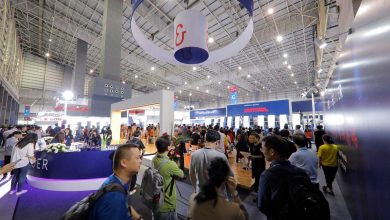

The trade show is dead; well if it is, no one thought to tell Fespa. With a courage and enthusiasm more akin to a youthful age, this stalwart of graphic arts trade exhibitors launched Fespa Digital at the Messe Munich. It was clear from the crowds vying to get in on the very first morning and the crowds that followed on the following days that its timing was perfect.

Canon also read the Runes as well, it anticipated the likely success of Fespa Digital some months previous and organised a seminar and mini expo called ‘Canon for Business 2014’ to run in the two weeks prior to the start of the events at the Munich Messe. Journalists and Canon partners from around the world including 55 partners and key customers from the Middle East were flown in to Munich to broaden their perceptions of what is possible with commercial and wide format print.

The giant is rising

Canon is coming to be seen as a new giant in the print and publishing sector, its star is rising rather strongly and though it has yet to eclipse many of the leading Litho players, all the signs are that this is only a matter of time.

There is a stream in Canon’s DNA possibly more overlooked than recognised which plays a very important role in Canon’s success and that strand began not far from Munich at Pöing around 20 years ago. Here Siemens Nixdorf then Germany’s equivalent of IBM created an astonishingly sophisticated facility to produce state of the art dot matrix printers. Here was one of the first almost fully automated assembly line of its kind and the printers were driven by software that depended on database management. The next important stream of Canon’s DNA came when Océ acquired this site and its technology and converted the dot matrix skills to Postscript and began to exploit the fast developing toner and inkjet technologies and in the process creating the world’s finest transactional printers. The final contribution came when Canon always the perfectionist took Océ in to its fold.

There is a stream in Canon’s DNA possibly more overlooked than recognised which plays a very important role in Canon’s success and that strand began not far from Munich at Pöing around 20 years ago. Here Siemens Nixdorf then Germany’s equivalent of IBM created an astonishingly sophisticated facility to produce state of the art dot matrix printers. Here was one of the first almost fully automated assembly line of its kind and the printers were driven by software that depended on database management. The next important stream of Canon’s DNA came when Océ acquired this site and its technology and converted the dot matrix skills to Postscript and began to exploit the fast developing toner and inkjet technologies and in the process creating the world’s finest transactional printers. The final contribution came when Canon always the perfectionist took Océ in to its fold.

So three dynamic strands of DNA have been brought together: German manufacturing skills, Dutch entrepreneurial skills and the Kaizen philosophy of constant and continuous improvement and Fespa Digital in Munich presented a golden opportunity for Canon to leverage the wonderful asset it has at Pöing. Canon for Business 2014 bordered on a full size expo drawing around 2600 business leaders to view demonstrations of Canon’s latest developments in digital printing technologies and hear talks on the direction it sees the sector moving.

Pöing fairly sizzled during the event. The Canon site covers more than 6,000 square metres, employs around 1,000 people yet it is just one unit of a large modern technology based industrial estate handy to Universities and technical colleges. Canon at present is using the site to assemble a variety of printers and also its newly developed Arizona flatbed printer in part because the demand is proving so great the Canadian factory where it was first developed is in danger of being overwhelmed.

Using its Munich facility proved to be a wise move on Canon’s part. Often these type of seminars take the form of preaching to the converted, but Canon had plenty new to say and the numbers wishing to come were more than willing to listen and most came away evangelised by the Canon way of doing things.

Canon for Business 2014’ was divided into four forums: Insight, Inspiration, Delivery and Support. Fairly self-explanatory such titles but they did suggest there was something for everyone and the new launches covered high speed continuous feed, cut sheet production, and wide format digital sectors.

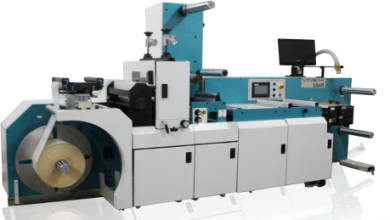

Technological highlights included a high speed inkjet system – the Océ ImageStream 3500 – able to print on offset coated paper stocks (availability from the beginning of 2015); the Océ VarioStream 4000 Series of black and white dry toner continuous feed presses and a new entry level VarioStream 7110/7170 models (also mono and continuous feed).

Canon said it has already sold its first ImageStream 3500 – a 30-inch wide inkjet system that is capable of printing at up to 160 metres (525 feet) per minute at 1200 x 600 dpi. This uses a new pigment ink set that has been optimised for use with standard offset coated media.

Peter Wolff, director of Canon Europe’s Commercial Printing Group is pretty upbeat the prospects for this new range. He says: “The Océ ImageStream rivals the speed and image quality of offset technologies, such as conventional B2 presses, while harnessing the capabilities of digital printing technology for shorter runs, print-on-demand and variable data.”

Project Niagara

Surprisingly what excited the punters most didn’t even have a touchy – touchy feel about it at all; it was a conceptual video of an exciting development Canon has given a code name to: Project Niagara and claimed will fill the gap between cut sheet and entry level continuous feed production.

The imagePress 800 Series is due to ship from July 2014. It is aimed at customers with a duty cycle of 20,000 to 100,000 sheets per month, and can print at full speed (80 pages per minute) on media up to 220 gsm, while being able to handle media up to 300 gsm at lesser speeds. The system is packed with new technology to improve quality and flexibility. This includes the new Consistently Vivid (CV) toner, improved registration and colour calibration tools, and a 32-beam VCSEL laser unit that delivers 2400 x 2400 dpi resolution. There is a choice of front end technology, including a Prisma-based one, and EFI Fiery-based options, either embedded or external, using the new Fiery FS150 platform, which Canon is the first to use.

The machine at present is undergoing strenuous pre-production trials at five customers in Germany and the Netherlands and the target market will be companies with a demand of around two to three million prints per month.

The machine at present is undergoing strenuous pre-production trials at five customers in Germany and the Netherlands and the target market will be companies with a demand of around two to three million prints per month.

David Preskett, professional print director for Europe sees Project Niagara as it is styled at the moment as a real game changer. Canon has in effect produced a digital printer that has the attraction that magazines, catalogues and books can now be produced digitally indistinguishable from litho, and this facility offers two attractions to printers. The first is the body of a catalogue, magazine or book can be printed offset with personalised inserts printed using the imagePress800, or a prelaunch edition of a long run job can be produced to test the market.

Canon for Business 2014 proved to be quite a warm up for Fespa Digital, yet for all its gloss, in some ways the surprises had only just begun. Munich was to show off quite a number of flatbed printers, all of them very good, some like Durst’s were outstanding in a very specific way, but for versatility and usefulness and tempered for the widest market the new Océ Arizona 6100 series will take some beating. It has a large flatbed, 2.5m x 3.0m, with an extremely advanced vacuum technology that ensures a wide range of materials can be held securely. Fair enough you might say, you would expect that, but to an observer the cleverness lay in the ergonomic efficiency of the layout.

Thanks to two independent printing zones, a single operator can have two sheets in play at the same time, for as soon as the first sheet is placed against the register pins, printing can begin and the operator now gets the second sheet in position against the second set of register pins. Clever, no doubt about it, but the real plus is the way the operator can load and unload or turn the sheets over with hardly more than a single pace in any direction and without any back strain. It is not hard to see that the Dark Overlord of Production would have an operator managing two machines at the same time and would expect around at least 50 sheets an hour. The register system ensures accurate back to back register though the software layout would have to take in to account layout e.g. work and tumble or work and turn if the initial pre sheet cutting is not totally accurate.

Ergonomic benefits though considerable are only attractive if its printing credentials cut the mustard. The Arizona 6100 series is rather special in this regard. It comes with Océ’s VariaDot technology and the 06–42 picolitre range delvers near photographic quality and here the Canon heritage comes in to play. Two additional ink channels are available, ideal for white applications and light colour inks are supported. The print heads contain almost 27,000 piezo electric fired nozzles arrayed in a seven row print carriage enabling 155 sq. metres per hour printing speed.

Mike Edwards head of professional business solutions Canon USA when asked where he saw the Arizona fitting in to today’s printing industry he said: “Canon is a solutions provider so we generally find that our clients and potential clients have a good idea of what their business needs are. It is up to us to ensure we can provide them with the right products.”

Mike Edwards head of professional business solutions Canon USA when asked where he saw the Arizona fitting in to today’s printing industry he said: “Canon is a solutions provider so we generally find that our clients and potential clients have a good idea of what their business needs are. It is up to us to ensure we can provide them with the right products.”

Watching the Arizona 6170 being demonstrated almost automatically triggered the notion that an investment like this is only part of the story, a flatbed cutter is almost certainly a companion investment and this is a point on which Mr. Edwards concurred: “Yes our ProCut Digital Flatbed Cutter is certainly an option. He went on to point out that most clients will have shopped around so it was important for Canon to have a good relationship with several providers to ensure a printer finishes up with a solution that serves his needs.

The Arizona series of flatbed printers are joining a wide and divers range of print and production options and Pierre-Olivier Esteban Canon’s technical marketing director says: “Fespa is one way we can show how Canon can meet the modern printer’s challenges and we are able to demonstrate the true potential of Canon technology some of which they may already be using.