A Time For Labels

Label industry is undoubtedly booming everywhere. Consumers are more demanding now and product safety and vital information in multiple languages must be printed on labels for food products. Label has become an inseparable part of packaging. New safety regulations and consumers’ self awareness have contributed to the technological advancement of label production technology.

Many commercial printers mulling whether to invest in label production lines. Despite the rise in demand for labels and increase in number of labels printed globally this seemingly future proof industry is also trying to come to grips with new realities and trends.

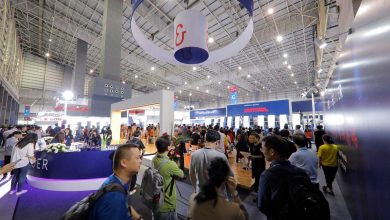

Following the global printing industry trends runs are also getting shorter in label printing. However there is now more variety and higher demand for personalization, versioning as well as added value and special effects. One of the ideal places to find out about what’s hot and what’s not in the world of label and labelling is Labelexpo Europe. The show’s 2013 edition is set to become the largest in its 33 year history. The show will return to Belgium between 24 and 27 September.

With more than 31000 sqm of exhibition space the event will fill all seven halls of Brussels Expo. All the top brands including AB Graphic, Avery Dennison, Codimag, Domino, Durst, EFI, Gallus, HP Indigo, Mark Andy, MPS, Nilpeter, Nuova Gidue, Omet, Prati, Stork Prints, UPM Raflatac and Xeikon are already signed up for the label industry’s biggest show during 2013.

This year Tarsus group- the organizer of the show- has come up with a new initiative. The new feature which is called Inkjet Trail will highlight all the available inkjet technologies and offers an opportunity to visitors to judge and compare their performance while producing identical designs on the same label stocks.

Six major inkjet printer manufacturers including Domino Printing Sciences, Durst Phototechnik, EFI Jetrion, Epson Europe, Heidelberg Linoprint and Stork Prints will take part in this initiative by producing a selection of food, pharmaceutical and industrial labels using the same sets of origination and on the same range of substrates. Xeikon will be printing the same label designs to show the quality of its toner based technology.

Hybrid Solution From Gallus And Heidelberg

Heidelberg which is now very selective when it comes to participating at international shows will have presence at Labelexpo Europe along with Gallus who will be using its Gallus Print Shop concept to demonstrate how the benefits of digital and conventional printing methods can be combined to produce labels faster and more cost-effectively. The Gallus Print Shop at Labelexpo will feature the new Gallus ECS 340 with the “Plus” update package, the Linoprint L digital drop-on-demand (DoD) system from Heidelberg with the Gallus ECS C digital finishing solution, and the Gallus EM 430 S with the short-web concept. The Print Shop will combine and control the entire order planning and processing workflows of the three machine systems via central MIS workflow software. In cooperation with its industrial partner Siegwerk, Gallus will also be demonstrating the benefits of LED UV drying technology on the Gallus EM 280 using the latest UV LED inks from Siegwerk.

Heidelberg which is now very selective when it comes to participating at international shows will have presence at Labelexpo Europe along with Gallus who will be using its Gallus Print Shop concept to demonstrate how the benefits of digital and conventional printing methods can be combined to produce labels faster and more cost-effectively. The Gallus Print Shop at Labelexpo will feature the new Gallus ECS 340 with the “Plus” update package, the Linoprint L digital drop-on-demand (DoD) system from Heidelberg with the Gallus ECS C digital finishing solution, and the Gallus EM 430 S with the short-web concept. The Print Shop will combine and control the entire order planning and processing workflows of the three machine systems via central MIS workflow software. In cooperation with its industrial partner Siegwerk, Gallus will also be demonstrating the benefits of LED UV drying technology on the Gallus EM 280 using the latest UV LED inks from Siegwerk.

The Gallus Print Shop concept combines the advantages of digital and conventional printing methods by networking the individual presses and centrally controlling the production process using MIS workflow software and operating data capture.

The new Gallus ECS 340 with the “Plus” update package which will be on display delivers key technical improvements and paves the way for opening up additional areas of application. The recent signing of an international sales and service agreement for the Linoprint L digital printing systems from Heidelberg enables Gallus to add the Linoprint L digital drop-on-demand (DoD) system from Heidelberg to its portfolio.

The Linoprint L uses the drop-on-demand inkjet method and supports a resolution of 600 dpi and a printing speed of up to 48 metres per minute in four-colour mode. This makes the system an addition for high-quality flexographic, offset and screen printing applications where small batches need to be produced as and when required or variable data needs to be printed on prefabricated labels. The digital printing system is also suitable for new applications such as smart labels, security printing or trackable labels.

At Labelexpo, the Linoprint L will be demonstrated live in combination with the Gallus ECS C digital finishing solution. Gallus will also showcase EM 430 S narrow web press which has a shorter web path and uses quickchange sleeve system. The combination printing press can be configured to include UV flexographic printing, rotary screen printing, hot foil embossing, cold foil printing, relief embossing and diecutting. In cooperation with its industrial partner Siegwerk, Gallus will be using Labelexpo 2013 as a platform to showcase a Gallus EM 280 equipped with a complete LED UV drying system that uses the latest UV LED inks from Siegwerk and state-of-the-art radiators.

Gallus will also be the only manufacturer to demonstrate live production of a label that combines the benefits of digital and flexographic printing and is dried entirely with LED UV technology. The event will be used as an opportunity to demonstrate the unique multiprocess capability of the Gallus RCS machine as well as Gallus Screeny Genuine screen printing plates.

What Has Efi Got Up Its Sleeve?

EFI is planning to show the latest upgrades to its Jetrion modular end-to-end digital label system which features inline varnishing and lamination, laser dieless cutting and rewinding options. The combination of digital technology and industrial construction has resulted in a fully integrated unit. According to Mark Verbiest, Efi’s international public relation manager Jetrion is able to reduce waste by only printing the stocks that are needed, saving energy and reducing turnaround time. By using a digital end-to-end system, make-ready is also faster and the integrated finishing incorporates cutting, slitting, back-scoring resulting in finished rolls at the output end. This enables consistent faster working, with no outsourcing or the need to work on multiple devices. The benefits of digital production are key to increasing flexibility in label production across low and medium volumes, giving convertors growth opportunities into new markets where shorter runs can now be generated without cost or time penalties.

Mark Verbiest also maintains that offset, screen and flexo print businesses can now benefit from moving into the digitally produced label sector by combining EFI’s production software with Jetrion’s flexible capabilities. He says,” Label printing is moving increasingly to digital systems but EFI is able to bring convertors all the necessary production business software as well as a truly integrated machine. This enables print companies to become more innovative and versatile in what they can offer customers. Diversification is key to printers today, and so is accountability.” He adds,” investing in Jetrion gives users a single-step system which removes the need for specialist finishing capabilities, and incorporates a true end-to-end platform which includes production software. Inline laser cutting takes away the need for conventional dies, resulting in a cost-effective print-and-cut system which is straightforward to set up regardless of volume.”

Omet Celebrates 50th Anniversary

This year’s Labelexpo Brussels is a special one for OMET that has just turned 50. The show will be the occasion to announce technological news for the label and packaging sectors and consolidated market results.

OMET will put on display XFlex X6 with sleeves as well as XFlex X4 which company claims has become an international hit. The XFlex X4 will handle in Brussels some interesting print jobs, which enhance the potential of the machine in terms of quality and reliability.

XFlex X6 configuration presented at Labelexpo Europe 2013 is a mix of flexo and offset technology. The newly born offset units are equipped with light sleeves to increase further the machine benefits in terms of rapidity of change, user-friendliness and general ergonomics.

The XFlex X6 with sleeve offset is typically dedicated to packaging printers who need to rely on offset to reach the maximum replicability of printed works. The mix of offset and flexo allows taking advantage of the plus of both, including for the second the low cost of prepress, the ease of ink management and the inner process flexibility. The XFlex X6 in the flexo+offset configuration is offered in widths up to 670 mm. OMET is also integrating in its offer the Varyflex presses in larger widths, up to 850.

Innovation According To Prati

PRATI Company will premier the very latest solutions developed by its R&D department. The way the Company is approaching Brussels is marked by founded optimism, as is confirmed by Chiara Prati, Sales Director of PRATI Company: “Following what is a completely counter trend with respect to the economic crisis, over recent years the company has grown exponentially. 2012 was our record year in terms of sold units and the turnover for the first six months of 2013 has more than doubled compared to the previous year.”

PRATI Company will premier the very latest solutions developed by its R&D department. The way the Company is approaching Brussels is marked by founded optimism, as is confirmed by Chiara Prati, Sales Director of PRATI Company: “Following what is a completely counter trend with respect to the economic crisis, over recent years the company has grown exponentially. 2012 was our record year in terms of sold units and the turnover for the first six months of 2013 has more than doubled compared to the previous year.”

The company will show STARplus which is considered an alternative solution developed for customers that do not need an inspection system. It uses a glueless technology during lane’s hooking and uses labels (with optional ID) to close the rolls. The STARplus off-line turret (four shafts) works in-line with any printing and converting machine. Its full servo technology makes it fit for the new ECO very thin materials, too. It also ensures high speed and cycle continuity thanks to quick and automatic spindle change. A complete job change over needs only 15 minutes.

PRATI Company also presents the SA Dual Turret semi-automatic rewinding system, which fits to the latest-generation SATURN and JUPITER models. ; The production outputs in new models have increased by 50%. At Labelexpo, PRATI Company officially enters the packaging industry; its brand new ALHENA IML series is focused on one of the segments most strongly affected by technological value added: In-Mould-Labelling (IML).

ALHENA IML converting machine accommodates large mother reels; it’s equipped with re-register die and a conveyor unit which conveys the labels to the stacker, where they are automatically stacked to make packaging easier for the operator.

New Range Of Solutions From Durst

Durst will launch a new range of solutions for the label industry at the Labelexpo 2013. For a complete digital end-to-end workflow, the Tau 330 high speed UV inkjet label press will be showcased with in-line digital laser finishing that incorporates laser die cutting technology from Spartanics, with powerful 1000 watt laser for high productivity and automatic job changeover to handle multiple jobs in a single run. Durst will also introduce the new Tau Low Migration UV Inks from SUNJET. The Tau Low Migration ink components all appear on the Eupia and Swiss Ordnance positive lists and do not utilize material specifically excluded on the Nestle list, which when combined with the specially designed UV curing system can achieve migration limits of less than10ppb.

The Durst Tau 330 together with this ink will expand the range of suitable applications for unsupported foils, such as blister packs, yogurt lids and many more. Depending on application requirements, Tau 330 users may now choose from 2 different Tau UV inkjet inks: The standard UV Inkjet Inks for all industrial applications or the very new Low Migration UV Inkjet inks suitable for food, health care and pharmaceutical applications.

To cover a broader range of applications, the Tau 330 is now also suitable for applications using Non-PS materials.

A second Tau 330 press will be demonstrated at the Durst booth with built-in Chill Roller, thus allowing printing unsupported films and foils. Also shown will be the built-into the press high-resolution Video Inspection System from NIKKA. The system automatically detects print defects while printing.

Live Performance By Vinsak

VINSAK, provider of products and solutions for printing and packaging industry will organize live performance of VINSAK LSR330 Label Inspection Slitter Rewinder along with VINSAK VIS 1200 Inkjet System. Also, the visitors can find out about VINSAK Brand Protection Solutions that contains security inks, software and other smart and secure products. This will be first show for VINSAK at Labelexpo Europe.

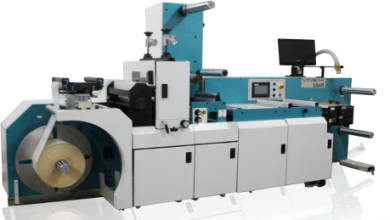

VINSAK LSR330, Label Inspection Slitter Rewinder is manufactured for ease of operation and PLC controlled to ensure total reliability and flexibility.

The VIS1200 is a modular wide format inkjet printing system. The VIS 1200 can print on a variety of different papers, i.e. various offset papers, coated paper, gloss papers etc. The user interface is easy to handle, offers a good overview and with its Windows technology it is truly intuitive, claims the manufacturer.

The company will also showcase brand protection solutions including security inks, security software, security substrates hot stamping and track & trace.

A Not To Be Missed Event

Despite recession and budget limitations all the major players in the label industry are present at Labelexpo. This exhibition along with Fespa has managed to thrive. The reason is obvious label industry is growing and companies are delivering new applications and products to keep up the pace with the changing needs and demands of consumers. On the other hand other sectors of printing which traditionally were not interested in label now want a piece of action. Labelexpo will present them with the opportunity to find out about the latest trend and also to become a part of label industry community.