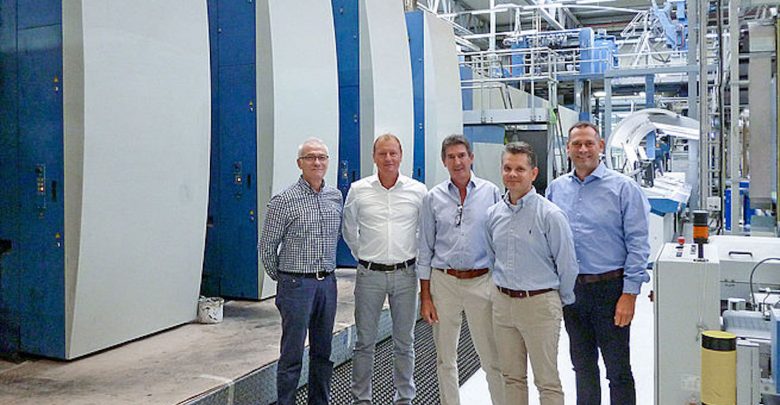

T’Hooft Invests in a Koenig & Bauer Compacta 818

Belgian printing company T´Hooft is continuing its growth curve with an investment in a second Compacta 818 from Koenig & Bauer. In spring 2019 the company’s third Koenig & Bauer press will go into operation in Aalter, Belgium, alongside a Compacta 106 and a Compacta 818. Bruno Braem managing director at T´Hooft: “Our new press meets exactly the requirements we were looking for. We are incredibly satisfied with our two existing Koenig & Bauer presses and we have worked very well with the press manufacturer for years. We are looking forward to receiving our new press as it will strengthen our solid market position even further.“ The press can pump out up to 45,000 80-page copies per hour. “We are very happy to continue our successful and trusting partnership with T´Hooft,” says Jochen Schwab, sales manager at Koenig & Bauer Digital and Webfed.

Printing company T´Hooft was founded almost 70 years ago by Raphaël T’Hooft and has been owned by the family since then. After several moves and investments in modern technology, the print shop has been located in the north of Belgium for more than ten years. In addition to the high-quality printing of magazines, catalogues and posters, the company sees itself as a general print contractor. The company covers all process steps from the initial design to the finished magazine. T´Hooft offers online marketing services in addition to its printed products to keep up with the digital shift.

The Compacta 818 will be engineered for a cylinder circumference of 1,156mm (45.5in) and a maximum web width of 2,270mm (89.4in). It will be able to print up to 45,000 80-page copies per hour. The press line will be equipped with an automatic paper reel feeder, a Pastomat RC reelstand, pneumatic roller locks, four printing units with automated plate changers, a high-performance dryer from Contiweb with integrated afterburning, and a P5 pin folder for vertical-page production and delta fold products. An inline colour measuring and control system ensures high process stability and a LogoTronic production management system ensures the digital flow of job and presetting data, production monitoring and evaluation.