Summary And Conclusions On FESPA Digital 2014

Dr. Nicholas Hellmuth along with his team from Flaar Report were present at Fespa Digital. The following report is his observations plus some tips about how to get the most out of a trade show. The Article is exclusively written for ME Printer Magazine.

The HIGH SPEED wide-format expo

Efi featured high speed (and especially LED curing benefits). Durst was showcasing higher speeds. Oce and Fujifilm had larger machines with higher speed (in most cases due to having lots more printheads, sometimes twice the number).

A good visual example of this “HIGH SPEED” focus was the SCREEN dedicated flatbed. Their TruepressJet W3200uv HS was a high speed model.

My favorite products exhibited

My favorite products exhibited

Canon DreamLabo 5000 system Efi hardware and software are covered in a separate UV TRENDs report) Linen fabric which is actually polyester Matan print samples were impressive as well as new UV printer from Durst plus Efi VUTEk (the compact one: does not take up too much space). Honeycomb but plastic and cutter of two head (Elitron), Endutex material where among intelligent products showcased.

It helps when the photos are adequate resolution

Manufacturers and distributors spend a fortune to rent a booth, ship in their equipment, and then they showcase fuzzy or low resolution photos. Photos which do not have the pixel count to be covering an entire wall. And these weak photos are supposed to make us want to buy the printer which printed this image?

Already in 1997 we had a 24 megapixel camera (tri-linear scanning back from Better Light). By 2000 we had a 48 megapixel version. Today we have a “35mm” DSLR with 36 megapixels. Yes, a good photographer does not need fancy equipment, but…. If you are going to enlarge your image to cover the entire wall of an expo booth, it might be wise to use a high-res image.

At FESPA Digital there was no time for me to inspect media, cutters, or laminators (for this reason we had a team of four people). But what I did notice was lots of weak saturation backlit (and other see-through materials) in many booths.

If you are going to print backlit and feature it in your booth, be sure that your ink or image or material is well printed. Realize that some printheads simply are not very good at producing well saturated colors that pop on backlit (or the printer operator is not taking the time to set the RIP software options carefully).

So if you, as printshop owner or manager, are at an expo to buy a printer, be sure its printheads, its RIP, and its ink can produce a powerful image for your clients. Be sure to test this aspect in case the printer manufacturer cleverly avoids exhibiting this downside to their brand.

Best booth structure design

The MultiCam CNC router booth had a minimalistic appearance that was actually rather unique: a complete structure featuring the posts and banner frames, but devoid of anything else. The exhibit itself was appropriately matched (empty).

In artistic circles, minimalism is considered chic. Considering the number of booths filled with (sorry) left-over packaging and garbage, this MultiCam booth was clean as a whistle. Chemigraf had a dramatic booth design.

The KIP booth is innovative both at European expos and in the USA. In the separate FLAAR Report on booth architecture, we discuss such good booth designs as the PAPIJET KISCO booth and the surprisingly large FOTOBA booth.

UV-Cured Printers

UV-Cured Printers

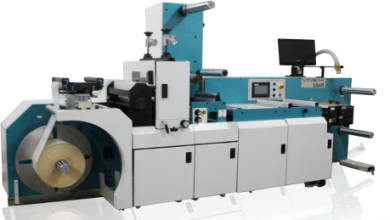

Most printers are understandably focused on signage. These we list in signage categories. But here we list the significantly fast throughput printers. In wide-format jargon, these are called “industrial” printers.

I prefer to reserve industrial for printing on 3D forms (Mimaki exhibited such a printer four or five years ago; not a “3D” printer, but a printer for round objects).

I personally would consider printers for glass, metal, and ceramics as an industrial printer. But printers which are really fast, and have special feeding front and back, these are simply high-throughput signage printers. They are printing on normal sheets and “boards:” they are not printing on any industrial materials.

The best examples at FESPA 2014 of fast-throughout UV-cured flatbeds were:

• HP Scitex 10000,

• Inca (in FUJIFILM booth),

• Efi VUTEk HS100

A second classification of faster-than-past-years-throughput would be the nice new Canon Oce Arizona 6170 XTS and the comparable Fujifilm Acuity F. The printhead carriage has significantly more printheads, hence the wider path and overall faster speed. However loading is manual (but you can load one end of the printer while it is printing at the other end).

The HP Scitex FB500 would not be accepted by many analysts as “industrial.” This is a mid-range signage printer; it is not an industrial printer: definitely not in speed; definitely not in feeding system, and definitely not really for printing on industrial materials.

The INDUSTRIAL PRINTER sign of HP was facing a true industrial printer at one side (HP Scitex 10000) and a host of industrial printers across the aisle in the Durst booth. If you compared the HP Scitex FB500 with any of these, you would see and understand why the sign INDUSTRIAL PRINTER was not a very clever idea (since it drew attention to the lack of industrial aspects).

A colleague in the printer industry (in Texas) was just about to buy an HP Scitex FB700 about 3 years ago; he said when they found out he was also looking at an Efi VUTEk the HP salesperson dropped the price.

Mimaki, Fujifilm and Colorific introduced SUV printers. The nice article on SOLVENT UV, in Issue 2 of Fespa Daily, totally missed the Fujifilm printer with SUV ink. Was this article written before the expo started? Fujifilm launched their SUV ink at FESPA.

Solvent Printers

Mimaki was about 50% UV, SUV, 10% textile printers, and perhaps 40% eco-solvent or Latex. Until I see an MSDS and have an in-person discussion with an ink specialist, it is safest to classify most latex ink as a kind of solvent water based ink. Whether HP latex ink has more solvent than Mimaki would be an excellent question. It is notable that no trade magazine has done such a lab test.

Latex Ink Printers

No Ricoh booth; so no Ricoh Pro L4160 latex ink printers. Their booth was far to the end of everything.

Memjet Technology

Xerox had 100% Memjet printers, so their nicely designed booth was 100% focused on Memjet technology and Xerox’s experience with producing the feeding and production aspects.

Flatbed cutters

Innovation is what counts. Precision and quality help, but graphic design is also essential. With flatbed cutters what I always enjoy seeing is the bees and spiders and monsters.

RIP Software

Caldera had a large, fully-stagged, and very busy booth. Wasatch tends not to have any booth but the President, and the key Latin America manager and European manager were all at FESPA. ErgoSoft, ColorGate, SAI all had booths.

Laminators & Coaters

Laminators & Coaters

Several laminator brands were present: mostly (but not all) made in China. At most perhaps two coater brands. Printer companies understandably hope that the entire print shop budget will be spent on PRINTERS. So many printer PR releases claim “NO lamination necessary.” Sorry, in most cases this is not true. You do still need lamination.

Coating is different; coating puts a special effect onto the surface. However coater manufacturers have not been effective in presenting their advantages. This is where a FLAAR Report would make a significant impact, but until we can visit the corporate demo room and visit an end-user who has the equipment, it is not realistic to begin an evaluation on a brand.

Laminator Tables

Six years ago there was only one major brand of laminator work tables: ROLLSROLLER. Yet every two years there is another brand; there is even a separate brand from South Africa. And starting about two years ago Chinese began producing low-bid versions: FeiYang is one of several. This year at APPPEXPO 2014 in July we will take note on how many Chinese brands exist..

At FESPA 2014 I noticed the following brands:

BMA Applicator

Bobis, www.bobis.nl, The Netherlands

Bubble-Free Applicator

Huber’s, www.hip-shop.de (distributor)

CUT Work Table

Paperlinx (distributor)

ModulMounter

flatbed laminator

www.modulMounter.dk, Denmark

Rollover

www.Rollover.no, so made in Norway

ROLLSROLLER

http://rollsroller.com/, Sweden

The following companies also make or sell flatbed applicators. It is not always easy to tell whether a company is a manufacturer or just a distributor putting their own brand on the product of a different factory.

Eastsign

www.eastsign.com, Hong Kong

Eezy Applicator

Ogwini Engineering, South Africa

EzyRoller

(Name used by Australian distributor)

Lamidesk

www.ilatec.de, Germany

Mounter’s Mate

www.mountersmate.co.uk, UK

Rapid Applicator,The Netherlands Graz, Austria would be one place we would like to do an evaluation of a flatbed laminator for a brand made in Europe. I lived in Graz for eight years while doing my PhD research and dissertation but I have not been back for over 23 years.

Since there are now about 10 different brands, the best way to learn which is which is to start by visiting a factory and then doing a site-visit case study (such as in Graz). As soon as we are flown to a factory we will do our evaluation report.

Plus it will be worth reporting how this technology began in the first place, and spread worldwide.

3D Printers at FESPA

Issue 1 of the Fespa Daily ran a feature article on “The exciting world of 3D printing.” But most of the “3D printers” actually on exhibit were only to sublimate onto cups or bottles. So these are not doing any 3D printing, they are only decorating 3D objects which already exist.

There was no significant presence of 3D printers whatsoever. I did not even notice a 3D printer in the Agfa booth (in their combined AGFA-PITMAN booth at US expos they show a 3D printer). And to repeat, most “3D printers” are not printing, they are laying down melted plastics. There are actual 3D printers, using either HP, Canon, or Ricoh printheads. But I do not believe that any of these were at FESPA 2014.

Printheads

It was surprising to see Mimaki launch two new printers still with Epson printheads. An Epson distributor told me that even as a Mimaki distributor he had a hard time obtaining DX heads for older models. Keep in mind that Epson stated openly and clearly what we were aware of all along: Epson wants the entire eco-solvent and dye sublimation market to itself (just like many years ago it effectively prohibited Mimaki, Mutoh, and Roland from continuing in the fine art photography, giclee, proofing or any other water-based market. Epson wanted this entire market for itself).

But as Canon water-based printers got better (and they kept launching newer iterations as new model numbers), and has HP had acceptable water-based HP Designjet Z-series available, the market for photo and giclee for Epson diminished. Head clogging, lack of significant speed, and weak backlit were probably the most discussed potential issues of Epson printheads of these past generations (DX 4, DX5 in particular).

But as Canon water-based printers got better (and they kept launching newer iterations as new model numbers), and has HP had acceptable water-based HP Designjet Z-series available, the market for photo and giclee for Epson diminished. Head clogging, lack of significant speed, and weak backlit were probably the most discussed potential issues of Epson printheads of these past generations (DX 4, DX5 in particular).

So starting a few years ago Epson entered the eco-solvent market with the GS6000. This turned out to be a good machine (evidently manufactured by Mutoh, in Japan). I have spoken with a print shop in USA who bought several Epson GS6000 and he really liked them, so much that he bought a new generation Epson SureColor eco-solvent printer.

Sadly these Made-in-China, low-bid printer systems are nowhere near the mechanical or functional standards of Mutoh’s factory for Epson Stylus Pro series (or whatever other factory in Japan may have been used by Epson in past years, before Epson jumped entirely to a Chinese factory).

Most UV-cured printers use Ricoh or Konica Minolta or Dimatix Spectra printheads. Oce and one Chinese factory use Toshiba Tec heads. Efi VUTEk uses Seiko heads. Only one manufacturer at FESPA was featuring Xaar printheads in a wide-format printer، the “Triangle” printers.

These are made by the same Italian factory which made heads for NEOLT. But NEOLT printer division is barely functional any more, so the Triangle booth was showing the two new printers with no NEOLT branding whatsoever. But half the people in the Triangle INX booth were from Italy.

I noticed only one person from Triangle USA, a very different kind of booth than in the days of Ken Kisner (whose family strated Triangle). Ken Kisner now works elsewhere.

Toner Printers & Desktop

Effectively zero toner printers: only perhaps as a toner printer for T-shirts. But no digital offset presses; no desktop printers. So no iGen printers in the Xerox booth: no desktop or even office printers in the Xerox booth (and curiously, not a single solitary printer in the Xeikon booth).

Trade Magazine booths

PrintWeek was in charge of Fespa daily. The company had a really large booth filled with people (all in a closed room, but with glass windows). The text was fully bilingual: Deutsch and English. I read the Issue 1, 2, and 3 but never saw an Issue 4. When I left the expo the fourth day at 4 pm, it was Issue 3 in the help-yourself bins.

Trade magazines help by bringing product launch info. Repeating PR releases without speaking with end-users is not informative Several trade magazines provide research statistics and articles.

My favorite trade magazines at FESPA

My favorite trade magazines at FESPA

SIP did not have a booth and there were no SIP magazines in the bins the day before the expo opened, so I have no recent issue. Same with most Spanish magazines: hardly any were in the bin at the main entrance to the expo the day before the show opened.

And most Italian magazines were missing (though about two were present). So I can’t compare or find my favorite Italian or Spanish trade magazine. PUBLISH of Russia did not have a booth but this is definitely my preferred magazine for Russia.

IndPrint was great because it clearly and precisely defines industrial printing. This was the first time I have seen this magazine.

ME Printer magazine is my favorite for the Middle East part of the world. Head editor Alex Jahanbani was present day after day, as were several of the guest writers for this magazine.

Lots of magazines from Turkey, but I did not notice any writer from SignGraphic whatsoever, nor did I see any of their magazines anywhere. But Dijital teknik had a hospitable and friendly booth and their key people were at the expo. I also see Dijital teknik at Sign Istanbul each year.

I did not see any issues of GD Pro, nor did I see Editor Michael Lyons. Also I did not notice ISM International Sign Magazine. The most impressive printer trade magazine from the UK was SignLink.

Expo Booths

Not many expo booths; VISCOM Germany I noticed, and KOSIGN tends to be present with a Korean trade magazine at most major expos. But otherwise not many expo booths. However some I may simply have not noticed since I was looking primarily for printer equipment

LED Signage

Tough to describe the total lack of LED and LCD dynamic digital signage exhibits. APPPEXPO in Shanghai has more than two ENTIRE HALLS with traditional signage, and the equivalent of one hall of LED and LCD dynamic digital signage.

I can understand the lack of dynamic digital signage in a screen printing expo, but even SGI in Dubai had more digital signage than the May expo in Munich.

Traditional Signage

EuroSign is a good try, but since there are special expos for traditional signage in China, it is understandable why the area and coverage is modest. But this year EuroSign was better integrated into the textile hall so to speak. The modest size is less noticeable when it is merged.

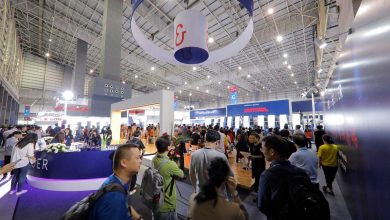

Attendence in General

Attendence seemed great the first three days, and even good the morning of the last day. By noon the last day attendance was down, as is typical of most signage and printer expos around the world. But the booth personnel of Efi VUTEk, Sam Ink and other companies said they had lots of attendance

Issues to resolve

This was a great expo and we encourage people to exhibit and attend FESPA Digital every year. But it is not a public service to pretend that everything is perfect. Actually it is a courtesy to point out the few things that hopefully can be improved for FESPA 2015 in Cologne:

– Exhibitors the day before said only one person was attending the long line to get exhibitor badges.

– Lack of PR at airport.

– Lack of U-Bahn or S-Bahn tickets or even discount. 10 years ago most European trade shows wrangled totally free transportation for all attendees. After all, we of the Press are writing about the expo (in theory encouraging people to visit the city). The least the city could consider would be local Metro and Tram tickets.

– Total lack of aisle names. This made finding booths time-wasting, especially.

– Total lack of booth maps at side doors

– Total lack of booth location maps at major cross-aisles

– Entry turnstyles seemingly did not function whatsoever. You had to be scanned manually by a human. Not a good ad for local organizational capability; a waste of human resources, a waste of time waiting for one or two people scanning your badge when there are 20 turnstyles locked down. It was stated that the expo center charged XY-thousand dollars to access their turnstyle system. Typical reason why trade shows are either flailing or often (as with VISCOM Madrid) failing.

– The badges has no plastic encapsulation system (probably cheaper this way). Downside was that if you had anything nearby it would scrape off the text so no booth person could scan-your-badge.

– No free shuttle bus to and from the airport. No free shuttle bus to any hotel (the Ramada and H2 hotels were within hiking distance, so no bus needed). And yes, there is excellent Underground and S-Bahn systems in every German city. But ten years ago the expo organizers would have wrangled a deal with the local city to provide a free pass for attendees and exhibitors: after all, we are all bringing lots of profit to the local city by attending FESPA.

– One company not exhibiting reportedly had a sign pointing to a bus to lead to an event offsite. I did not see this, but heard about it. The same company did this at an earlier FESPA several years back: invited people to visit their facilities by bus; this company did not have a booth at FESPA.

– Cell phone usage varied from difficult to impossible; but occasionally a call did go through. I find that about 50% of large expo halls have inadequate cell phone adequacy: in other words, most calls simply don’t go anywhere.

– Too many booths took down their exhibits early on the last day. This is not fair to attendees (and wastes the investment of the exhibitor also). It is the habit in Guangzhou and elsewhere for exhibitors to remove their exhibits as early as 10 AM on the last day; 50% of the exhibits are being removed by noon; and by 2 pm there is nothing left to see anywhere (other than major international brands who are trained to keep their booths open until official closing time).

Nice catalog at no cost

A full exhibitor catalog is available to all attendees at no cost. My compliments to FESPA organizers. Also a nice floor plan map was available. But it helps to have the list A to Z and not by booth numbers!

And would be even easier to navigate if there were aisles A, B, C, or aisles 100, 200, 300 etc. Splattered numbers suggests that the lists were not complete in time to print (or print them later so that there are fewer changes).

At expos in Russia and some in China, they charge too much for catalogs. Frankly expos need high attendee figures, so should be happy that anyone comes at all.

Almost no screen printers whatsoever

Almost no screen printers whatsoever

This is a compliment. Lack of screen printing equipment meant less awful odor. Any client who needs a new screen printing machine hopefully already knows where to find one. Ironically SGIA still has a large screen printer section.

I have a high respect for the screen printing industry, but the world is moving to digital, so technology expos correctly focus on what’s new.

It is nice that FESPA provides booth opportunities even for competitors: VISCOM Germany had a booth: though the booth rep was not knowledgeable about VISCOM or anything about the industry. She was simply a person to smile and hand out brochures. Yes, there were two actual VISCOM people in the booth, but often they were not present.

FESPA was twice the size of any expo in USA. Considering the size of USA, Canada, Mexico, Caribbean Islands and Latin America, you can see how FESPA is doing something to get such good size.

Shanghai expo in July is about 300% larger in size and has twice to three times more brands of wide-format printers; of inks; and especially of media and cutters. The Shanghai expo is about 500% larger than traditional signage exhibitions.

Nonetheless FESPA was a healthy size and we at FLAAR recommend FESPA in Europe (and FESPA Mexico). As soon as the dates of FESPA Africa are no longer the exact precise same days as APPPEXPO in July 2014, we will definitely

Focused FLAAR Reports

I have always been curious of why some companies keep improving and keep gaining market share (Efi VUTEk is an excellent example for the recent five years).

I am even more curious of why some companies fail: SigmaJet (formerly GRAPO) is one example. The rise and fading of Sun Innovations in Russia is definitey worth a thesis in an MBA program; same for L&P Digital Technology through WP Digital into Polytype.

Neolt is a good case study; years ago their booth would have been a major size. Yet now their booth was half the size of a minimal booth. Not a single Neolt printer was at the expo (though two printers from the same factory, but with no Neolt branding whatsoever, were in the Triangle INX booth). The only place I have seen a Neolt UV-cured printer is in China; the distributor there seems to have a final machine they have been trying to sell for several years.

The renamed Neolt web site shows two printers for sale, but they are not exhibited at major expos: zero in ISA sign expo for example.

Closing Observations

This was clearly a very successful expo. Attendance was excellent first three days, and morning of the final day. But there are several things which could be done to raise attendance dramatically.

Since I attend expos around the world for 15 years, I can note which countries have major numbers of people here. For example, Slovenia and Croatia were well represented: many came up to introduce themselves, or if we already knew each other, to say hello.

But there were several world areas where FLAAR Reports are popular and people in these world areas indicate to us that they tend to attend those expos which FLAAR announces far in advance. However we have no booth nor any association with FESPA. There will be two giant exps in the months immediately before FESPA. So despite the frankly wonderful venue of Cologne, the year 2015 will have the most struggle among expos for the periods January through May.

But there were several world areas where FLAAR Reports are popular and people in these world areas indicate to us that they tend to attend those expos which FLAAR announces far in advance. However we have no booth nor any association with FESPA. There will be two giant exps in the months immediately before FESPA. So despite the frankly wonderful venue of Cologne, the year 2015 will have the most struggle among expos for the periods January through May.

Autumn schedules will be normal: no major earthquakes or Tsumanis here. Even summer of 2015 will be relatively peaceful. Hopefully in 2015 we can return to recommending FESPA Africa now that hopefully the 2015 dates will not be the precise same days as APPPEXPO 2015. And FESPA Mexico is always an event we have respected. Ten years ago it was very clear that thermal printheads produced more saturated (more colorful) backlit than piezo heads (which in those years meant Epson printheads). HP, ColorSpan and Encad tended to produce noticeably better backlit.

In various booths there were backlit prints which were a tad weak. And in the metro stations (unrelated to FESPA), there were real-world backlit which were pathetic. Of course even with thermal printheads you can produce a wimpy backlit if you use the wrong settings in your RIP software. I have no way to know which printhead did these pathetic backlits in the subway station. But I would rather use these than show all the examples from too many booths.

All printers are really good at some applications, are okay at other applications, but are simply not perfect for other materials or applications. Thus it might be advisable to showcase what your printer is good at, and be realistic at what another technology can do better.