State Of The Art 3D Printing Technology At The Service Of Art

Dubai is one of the fastest developing cities in the world and one of the most technologically advanced as well. A slew of eye catching and technologically advanced buildings have already been built across the city.

The iconic Burj Khalifah is a prime example of sheer imagination of rulers of the country to thrust the United Arab Emirates into the global spotlight.

Now Dubai has stepped up its efforts to offer something unique to the world. It is called the Museum Of Future. Sheikh Mohammed bin Rashid Al Maktoum, Vice President and Prime Minister of the UAE and Ruler of Dubai, recently unveiled a fascinating and bold plan to construct a $136 million museum, innovation lab, and invention hub located in the Emirates Towers area near Sheikh Zayed Road in Dubai.

Based on report published in Khaleej Times and 3dprint.com the museum will be futuristic in every sense of the word, from its content to its ‘innovation labs,’ which focus on education, health, smart cities, energy, and transportation, to the very construction of the building which houses it all.

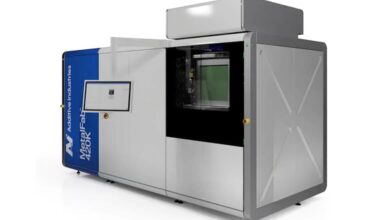

In fact, the government plans to use advanced 3D printing construction techniques to help build the curved, oblong, oval-shaped structure. The exact techniques which will be utilized have yet to be revealed, but 3D printing will play a crucial role.

After all, where else would you expect to find the world’s first $100 million+ building which takes advantage of 3D printing, than in Dubai?

“The world is entering a new era of accelerated knowledge and great technological revolutions. We aim to lead in that era, not to follow and lag behind.

The ‘Museum of the Future’ is the first step of many to come, marking the beginning of great achievements,” stated Sheikh Mohammed bin Rashid.

He also tweeted: “Museum of the Future is integrated environment empowering creative minds to test, fund and market ideas for futuristic prototypes and services.”

Based on a report by WSJ the oblong exterior actually incorporates lines from Sheikh Mohammed poetry. Apparently the interior hollow of the oval building will also contain some sort of holographic billboard.

The museum will be futuristic in every sense of the word, from its content to its ‘innovation labs,’ which focus on education, health, smart cities, energy, and transportation, to the very construction of the building which houses it all.

In fact, the government plans to use advanced 3D printing construction techniques to help build the curved, oblong, oval-shaped structure.

If all goes as planned the building will open to the public sometime in 2017, with a game plan to change out all the content of the museum every 6 months, ensuring that they are always looking 10 years into the future.

More than just a place to learn and imagine the future, with a motto of “See the future, create the future,” some of the world’s brightest minds will be within the facility inventing and working on applications that could take humanity to new wonderful places.

It will be interesting to watch as this incredible building begins construction and what the role of 3D printing will be during that process.

It will also be very interesting to see how much of a presence 3D printing has within the content of the exhibits as well.