Round Up On Labelexpo Europe 2015

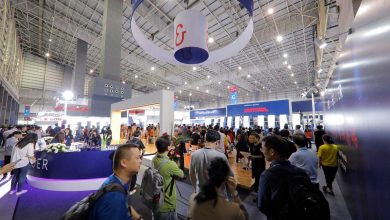

Labelexpo Europe reported record breaking results as it posted new visitor, exhibitor and exhibition space figures for its 2015 edition. Held at Brussels Expo from 29 September to 2 October, the show enjoyed its largest edition as it marked its 35th anniversary.

Attracting 35,739 visitors, attendance figures were up 12.4% on 2013’s total of 31,795. Visitors came from 146 countries, with most attending from Germany, France, Italy, Belgium and the UK. The show also posted an increase in visitors from outside Europe with 19.6% of the total visitors traveling from elsewhere including Asia, North and South America and Africa. Covering 34,566 sqm, the show’s foot print also increased by 11.65% on 2013, while exhibitor numbers rose from 600 to just over 650.

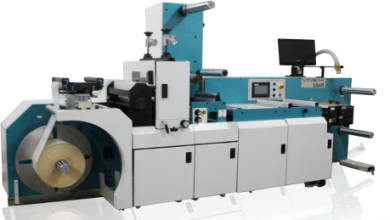

Held every two years, Labelexpo Europe is the world’s largest event for the label and package printing industry. Dominated by new product launches, the show again saw many major new developments being unveiled including Soma Engineering’s Optima 820 press for labels and packaging and the Gallus DCS 340 which is Gallus’ first ever modular digital converting system: an inkjet printing module integrated into a Gallus machine platform combines the latest digital printing technology with the benefits of conventional printing and further processing technology. Other highlights included new digital presses from leading manufacturers such as EFI, Epson and Screen. HP Indigo also showcased its HP Indigo 20000 and WS6800 digital presses, while Mark Andy showed it’s both its Digital Series and Performance Series P4 and MPS, Nilpeter and OMET debuted their hybrid conventional and digital presses.

Held every two years, Labelexpo Europe is the world’s largest event for the label and package printing industry. Dominated by new product launches, the show again saw many major new developments being unveiled including Soma Engineering’s Optima 820 press for labels and packaging and the Gallus DCS 340 which is Gallus’ first ever modular digital converting system: an inkjet printing module integrated into a Gallus machine platform combines the latest digital printing technology with the benefits of conventional printing and further processing technology. Other highlights included new digital presses from leading manufacturers such as EFI, Epson and Screen. HP Indigo also showcased its HP Indigo 20000 and WS6800 digital presses, while Mark Andy showed it’s both its Digital Series and Performance Series P4 and MPS, Nilpeter and OMET debuted their hybrid conventional and digital presses.

As well as hosting the 12th annual Label Industry Global Awards which saw industry gongs go to Kurt Walker – FINAT’s former president, GEW, HP Indigo, Lake Image Systems and Lintec, Labelexpo Europe 2015 also included several new feature areas. The Packprint Workshop was well attended with live press demonstrations given by Xeikon using its 3500 for digital folding cartons and Nilpeter showing its FA* flexo press for flexible packaging capabilities. The Smart Packaging Lab covered some current developments in active and intelligent with contributions from Avery Dennison, Blippar, EyeSee and Seido Systems. The show also hosted the inaugural Linerless Trail which promoted the benefits of linerless labels with industry partners working together including Maan Engineering, Appvion, Henkel, MPS, Ravenwood Packaging, Ricoh, Sato and Bostik.

Lisa Milburn, managing director of the Labelexpo Global Series commented: “We would like to thank everyone who took part in this year’s show. The feedback has been genuinely phenomenal and our exhibitors have been extremely pleased with many of the press manufacturers experiencing record sales and lead generation. The main trends coming out of this year’s show are the continued move to package printing as we see more manufacturers bringing short run production printing presses, which backs up our strategy going forward, and the ongoing dominance of digital as more and more hybrid digital printing presses flood into the marketplace. We’ve had an amazing show with fantastic testimonials and it certainly is a fitting way to celebrate our 35th anniversary.”

Hybrid Solutions

At Labelexpo a number of companies introduced hybrid solutions. MPS showcase the new EF flexo press with an integrated high quality, seven color inkjet printer.

Domino Digital Printing Solutions launched the N610i integration module, forming part of a digital hybrid solution, all based on its 7 colour digital label press.

Visitors to stand 9A60 at Labelexpo Europe 2015 were able to view first-hand the new N610i variant, integrated with an AB Graphics Digicon 3, including flexo, varnishing, laminating and die-cutting stations.

FFEI Ltd, introduced a new configuration of the hybrid digital inkjet label press, Graphium, on Edale stand. The system on show benefits from the recently announced digital label workflow and increased print speeds, which significantly increase productivity and the number of finished label jobs that can be produced in a shift.

Demonstrating unparalleled application versatility, Graphium enables converters to target a broad number of label applications with digital. It offers convertors the ability to be both highly innovative and very efficient. Graphium can be configured with a range of finishing technologies, designed to add value and to finish the label or packaging in a single process. Graphium’s finishing options are automated and synchronised to complement the digital workflow and to minimise set up time and waste.

Kodak also advocated the hybrid solution in Labelexpo 2015 through its FLEXCEL technology. The company says the potential of large-scale digital printing for the packaging industry has not been truly explored yet but it holds promise for personalization, improved customer loyalty and integration with online campaigns. Kodak advocates for a hybrid solution that combines the speed, cost effectiveness and versatility of flexo printing with KODAK FLEXCEL plates with integrated inline high-speed inkjet components for package customization.

The new UV-LED solution on OMET presses was exhibited at on an XFlex X6 hybrid Flexo + Digital printing press. Omet says the benefits the UV-LED process brings to the printing industry are nowadays quite familiar. They primarily involve two different areas of the printing process: first is the elimination of heat-related issues, and the second relates to the savings involved in the process.

The new UV-LED solution on OMET presses was exhibited at on an XFlex X6 hybrid Flexo + Digital printing press. Omet says the benefits the UV-LED process brings to the printing industry are nowadays quite familiar. They primarily involve two different areas of the printing process: first is the elimination of heat-related issues, and the second relates to the savings involved in the process.

Because UV-LED is premised around a digital cool light system, it eliminates the warm-up and cool-down time inherent to the UV curing method; also toxins normally released by heat in the substrates are eliminated, as well as the ozone and mercury emissions. Virtually zero maintenance, reduced energy consumption (close to 50% reduction) for the curing process and elimination of the need for standby time contribute to keep general operating costs low.

When Labelexpo Europe closed in Brussels, the leading global narrow web machine manufacturer, Mark Andy, pronounced it ‘a resounding success’! The company claims interest and orders from many new customers and opportunities for the two new machines on European debut.

The new Digital Series was demonstrated to packed crowds during five live demonstrations each day. Mark Andy claims it is the first ever truly hybrid system, and displayed the most robust integration of flexo and digital printing, foil stamping and converting with multiple die changes of any digital technology at the show. The Digital Series ran at 74m/min (225 ft/min), which was one of the fastest inkjet performers at the show, and visitors were able to watch live demos of three complete job changes in only 10 minutes, including a substrate change! The company believes the Mark Andy Digital Series design and technology is truly groundbreaking and ready for commercial use, with Beta sites already selected, and machines being installed in the US – it has its sights set on Europe for early 2016.

Xaar, a major manufacturer of printheads also offered hybrid technology according to Xaar this year In particular there was a real excitement and buzz around the show for digital and in particular hybrid label printing technology.

The global launch of Xaar’s new versatile Xaar Print Bar System at the show created interest from OEMs, integrators and end user label convertors who were all keen to realise the benefits that a single colour inkjet print bar could bring through adding wide range of inks and fluids, including spot colours (K or CMY), protective lacquers, high-build spot varnish, heavily pigmented high-opacity under-surface whites, cold foil adhesives, metallics, etc.

Xaar says the current trend for hybrid printing, getting the best of both analogue and digital combined, shows that company’s print bar solution has come along at the right time to address the market need. Shown as both a stand-alone unit and integrated into the Graphium hybrid press, the Xaar Print Bar System a solution for those wanting to add inline digital capability to their analogue web and sheet-fed label presses.

But not everybody is excited about hybrid technology.

Francois Martin, worldwide Marketing Director for Graphic Solutions Business at Hewlett-Packard offers his observations regarding hybrid technology. He says.

“What make this year new and different from previous years? Until now, there was always a clear cut distinction between conventional printing and digital printing. At Label Expo 2015, a new category emerged called “hybrid” Presses. Don’t be seduced at first glance, as in the end you understand that it’s everything you don’t want.

These “hybrid” presses – an inkjet printing unit combined with flexo elements is neither analog nor digital. Whatever perceived advantages are gained by having a single machine is lost in the trade-off made by compromises across both the digital and flexo food chains.

At the other end of the spectrum is the latest HP Indigo WS6800 Digital Press with full color management including an embedded spectrophotometer. This press means you can print the exact same job across multiple sites and multiple presses – week after week, reprint after reprint. The excellent print quality is ensured by the automated color management system – no compromises here.

For larger print volumes and sizes, the HP Indigo 20000 is fast becoming the industry benchmark for digital printing of labels and flexible packaging.

One of the things that was cool and unique on the HP stand – was the Mosaic technology. A free software solution that enables printing designs directly from the Internet.

Similar to the recent “Share a Coke” campaign, Perrier is about to leverage Mosaic to make unique bottles designs for each customer. The campaign is about being “extraordinary” – and this is truly what happens when a bottle you designed makes its impact on your table and in your hands. Theses personalized labels are cool in many ways.

At Label Expo, I missed the clarity of conventional printing and digital printing. Telling customers both is possible in one is truly misleading. Label and Flexible Packaging Printing is about color consistency and quality for demanding brands – the hybrid solutions are going to make it even more complicated for brand owners and for Label Converters to explain.

Label Expo 2015 made is clear that digital is the path forward – the question is

which type of digital? Full digital or compromised digital. The traffic on the HP stand and the sales done at the show were impressive.

For those who did not made it to the show, the HP Hall featured a full range of innovations and presses demonstrating that HP is one step ahead in making the impossible possible.”