RE: GmbH and Comexi to Develop a Joint Solution

The plastic packaging industry is undergoing a significant transformation with increasing demands for efficiency, quality, and sustainability across the entire production process, including extrusion and the conversion process. The complexity of this conversion process demands meticulous attention to avoid errors in print quality, sealing, coating, lamination, and waste management.

The challenge lies in managing these processes, often handled by isolated solutions that hinder seamless integration with the broader production process. As a result, packaging producers often lack a comprehensive overview of their entire production process, missing opportunities to correlate printing, laminating, and slitting with other relevant process data. This inefficiency leads to error-prone and time-consuming attempts to optimize the entire production chain.

Partnership enables new level of transparency in the production process

A cooperation between RE: GmbH and Comexi is now tackling this challenge. The RE: GmbH is a corporate start-up of the Reifenhäuser Group, committed to enabling packaging producers to digitally connect entire shopfloors via the c.Hub Middleware, allowing them to constantly improve their OEE. Comexi is a pioneering solution provider for printing, laminating and slitting and recognized for its sustainable and comprehensive approach in the plastic packaging industry.

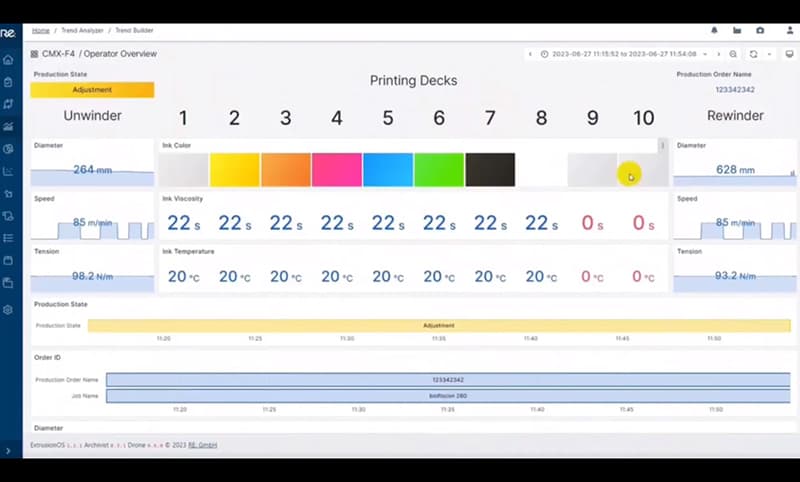

Together, RE: and Comexi aim to provide customers with enhanced insights into their entire production, including conversion processes. To this end, the companies are developing a joint solution, the Comexi-to-c.Hub package, enabling producers to securely access process data from their production lines. This includes all key parameters of the conversion process, spanning from printing to coating.

Key Challenges of Flexo Printing in Plastic Packaging Production

Utilizing highly accurate and cutting-edge machinery, such as Comexi printing presses, represents a crucial initial step in ensuring top-tier print quality. However, flexographic printing is a complex and precision-driven process that comes with its own set of challenges. Maintaining consistent quality across extensive production lines and finding the right balance between speed and accuracy to ensure efficiency are primary obstacles. Moreover, there is a growing emphasis on using recyclable materials, reducing waste, and enhancing energy efficiency.

Seamless Connection of Flexo Printing Presses to the c.Hub Middleware

Comexi is a leading manufacturer of flexographic presses, offering a range of models with advanced technological features and catering to the market’s diverse requirements. The “Comexi-to-c.Hub-Package” will be a comprehensive solution developed by RE: in cooperation with Comexi to seamlessly connect flexo printing presses to the powerful c.Hub Middleware and ExtrusionOS, its ecosystem of applications.

The c.Hub Middleware acts as a central point of truth, facilitating streamlined communication and data exchange across various stages of the production chain, including printing. This can lead to:

Improved Efficiency

The integration of printing data with the c.Hub Middleware optimizes the flow of information, enabling real-time data sharing between printing and other production processes. This minimizes the need for manual interventions, reduce errors, and enhance overall operational efficiency.

Enhanced Visibility

Packaging producers gain a comprehensive overview of their entire production cycle through the c.Hub as single point of truth. This visibility allows for better monitoring, analysis, and decision-making, ultimately leading to improved process control and resource allocation.

Synchronized Operations

The c.Hub Middleware allows the synchronization between different production stages, ensuring that actions taken in one area of the process are accurately reflected and executed in subsequent stages. This seamless coordination can lead to smoother workflows and faster time-to-market.

Reduced Downtime

The streamlined connectivity facilitated by the c.Hub Middleware helps to identify issues or disruptions more promptly. An early detection allows for faster troubleshooting and reduces unplanned downtime, contributing to increased production uptime.

Scalability

The c.Hub Middleware can accommodate growth and changing demands in the packaging industry. As businesses expand or adapt, the platform’s flexibility allows for easy integration of new technologies and processes.

Collaborative Opportunities

We aspire to cultivate a spirit of collaboration in the packaging industry through our partnership with Re:. This collaboration will involve the sharing of best practices, insights, and technological advancements, ultimately benefiting all those engaged in the sector.

Our objective is to usher in a new era of connectivity and optimization for packaging producers and converters. This forward-looking approach involves a full integration of converting processes in the future, in close partnership with both Re: and Reifenhauser. Through the consolidation of your data and the facilitation of seamless communication, we are committed to enhancing your operational efficiency, elevating decision-making capabilities, and empowering you to thrive in a dynamically evolving market landscape.