In Conversation with Jean-Pascal Bobst

ME Printer talks to Jean-Pascal Bobst , CEO of Bobst Group. He represents the fourth generation of the Bobst family in the company after Bobst Group was founded by his ancestor Joseph Bobst in 1890 in Lausanne, Switzerland. The company is a major force in the printing, packaging and converting industries, and the man at the helm of the group boasts an ambitious vision for the future of the packaging industry.

ME Printer: Let’s start with packaging film which has become a controversial issue prompting many companies to cut down on plastic film consumption. To give you an example, Procter & Gamble is planning to cut 50% of their plastic consumption by 2030. On the other hand, a major portion of BOBST business revolves around plastic film, which is not an environmentally friendly material. Do you think film has a future in the packaging industry? Do we need to rethink the role of plastic packaging?

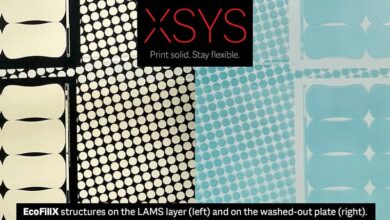

Jean-Pascal Bobst (JPB): Yes, of course. Film is under pressure due to sustainability and the main factor is also the lack of understanding of what recyclability is. Plastic on its own, if not recycled, has a bad impact on the environment. Now, for plastic or film packaging, we need to substitute them with polycarbonate or paper. But to do so, we need to treat polycarbonate or paper to achieve the same parameters and quality of such substrates. However, such a solution is not in the market yet because you need to create a barrier against humidity and light to increase shelf life. So, film will continue to be one of the most used packaging options for a long time to come, especially for food applications. But we are developing new solutions that, instead of multiple substrates from multiple sources like PET, PP, PE, utilize high barrier mono materials that are easier to recycle – we call it oneBARRIER. The aim is to educate people and work with governments to develop a chain of supplies, otherwise plastic will not be accepted by everybody. So, I do see a future for flexible packaging but with greater recyclability. It may not be a black and white answer, unfortunately, but film certainly has a future.

ME Printer: Back in 2020 you outlined a new vision for the future of BOBST which is seamlessly connecting the whole packaging supply chain and you also said top-level principles of connectivity, digitalization, automation, and sustainability were being transformed into a reality for customers. However, automated workflows have been around for many years and still many printers and converters are reluctant to adopt them, how long it takes and what does it take for this vision to become reality?

JPB: A vision is a vision. To make a vision a reality you need to align all the strategies and deliver it year after year – sustainable, effective variables towards this vision. In a nutshell, there are three main principles. First of all, this vision demonstrates that BOBST wants to deliver solutions from PDF to a finished good on the truck with a Twin PDF as quality certificate. BOBST will start, not with machines or services but at the prepress stage and be embedded in the workflow because you go to printing, converting, and delivering the goods on the pallet of the truck, and you want to deliver the goods with a Twin PDF to the client. The second principle is we want to digitalize most of the machines. Digitalize doesn’t mean digital printing only or digital cutting only. It means every BOBST machine, even analog, will be part a complete workflow and will be automated to the maximum capacity to reduce waste, optimize uptime, and ultimately, net output. The third principle is about how do we do this? We do so with BOBST Connect, which is a cloud-based platform, where you start from the PDF, create the right artwork that is used by the DFE (Digital Front End) piloting the machines. In short, from the PDF to printing, die-cutting or laser cutting machines. So, this digitalized workflow enables clients to connect to all types of equipment. We can also automate and digitalize machines according to their age. While machines from 2021 to 2025 will be ready for software upgrades, machines from 2010-2020 will be less digitalized due to their age. So, it is a long journey. We will certainly take 7 to 10 years to get there. But it’s a very powerful vision because in the end, it will really lead to productivity and quality improvements for clients. The vision will enable a better net output and increase their profits, and will also accompany our clients towards more sustainable solutions.

ME Printer: Corona pandemic disrupted many trends and created new ones, for the sake of argument if the pandemic never had happened would there still be so much emphasis on sustainability within the printing and packaging industry, and would your vision for the future of this industry be the same?

JPB: We designed and drafted this vision way back in 2013. We had to get ready to announce it and to gain credibility to market it because a lot of machines have already fulfilled up to 80% of the vision goal. This, in particular, is the narrow-wide web solution, the BOBST DM5 for example has already fulfilled 80-85% already. So, we are able to demonstrate to our clients that this is not just a dream. This is a reality. To answer your question about the pandemic, 2020 should have been a fantastic year. At drupa, we should have been able to show and present this vision with fun and passion. But that was not possible. The pandemic certainly pushed us to find new ways to accelerate, to find new ways to communicate with our clients and to increase decision making. The net outcome has been this vision to help the packaging world, to help our clients, and to become more sustainable and reduce waste.

ME Printer: With the growing interest and demand for sustainability many institutions and watchdog organizations who monitor and assess manufacturers compliance with sustainability guidelines have also emerged, for example, CEFLEX, which is a collaboration of over 160 European companies, associations, and organizations representing the entire value chain of flexible packaging, are you also part of this consortium or any other one? If yes, how do you contribute to the goals and aspirations of these institutions?

JPB: For now, we are only part of CEFLEX. It’s on the table to join more organizations. The question is where should we invest our time and energy and knowledge, and how can we help. So, what we do today is to develop with brand owners and substrate providers’ better solutions for water-based ink applications with recyclable capabilities. In the future, we will go ahead as it is part of our sustainability strategy. We will refresh for the coming year. As a market leader, we must educate and explain to our clients the benefits of every solution. Every packaging type has its benefits if managed properly. And I feel it is our role to bring more awareness to people and governments.

ME Printer: I am sure you have heard of the Circular Economy Action Plan of the European Commission as a cornerstone of the EU Green Deal. We see more and more packaging designed for recycling. Do you feel the goals of the Action Plan are achievable and if you had a voice, how would you advise governments to introduce legislative measures? Also, should we have legislation for use of certain materials in packaging?

JPB:

We have no impact on governments. But society needs to have rules and regulations to change habits because we don’t like to change. So, we keep going for the cheapest packaging options and nothing will change. For example, for the last 10 years, our clients in Europe have already paid taxes on film packaging for recyclability, support, and investments. Now, tell me which state in Europe has developed a recyclable rule for film? You have to be smart to do it. Rules and regulations might push people to recycle as we did for glass and cans. It’s a culmination of rules of accountability. Like we have low migration inks with many definitions. There’re a lot of rules and regulations, but who’ll really follow them? And for consumers, the most important requirement is transparency. For some packaging, it’s okay to have low migration inks because it is secondary packaging and can be recycled properly. But in some applications, there are cross buyers and the trust with consumers is broken and this is where we start to have problems. So, it is all about transparency, smart rules, and communication.

ME Printer: Recently BOBST launched ‘Generation 2.0’ samples of high barrier flexible packaging using mono-material film. Many top brands in the packaging film industry worked with you on this project, will we see more projects like this in the future? Also, will we see these products reach mass production or it is just an effort to show what can be done?

JPB We made a big investment in the special coating lines to make exactly this type of testing for brand owners, clients or substrate providers. And this line is fully booked for the next 10 months. This clearly shows that it’s a very big interest for the market and we will continue. I am sure novelties will come. Unfortunately, just like in the case of COVID where we needed months to develop a vaccine, finding the best chemistry for all types of substrates may take months or years. But novelties will come and we will be part of it. Having said that, BOBST has no influence to impose a standard on others. So, Procter & Gamble, Pepsi, and Mars – they will decide what they want to use, and hopefully, they would choose a solution that’s co-developed with us.

ME Printer: Bobst is entwined in the history of the packaging industry, in your opinion what are the major milestones in Bobst history that truly changed the packaging and converting industries for the better?

JPB: In BOBST, our value creation is based on three pillars – people, innovation and knowledge, and value creation financially. The main asset that BOBST is bringing to the market in the last decade is the right product, sustainable from the relationship, customer-client point of view, and of course to bring the right cost of the product; meaning reliability is important. When it comes to innovation, we came up with some major ones but it’s very difficult to measure how the market is able to cope with these advances. We presented oneECG (Extended Color Gamut) a few years ago for all our brands, all our printing technologies and I am quite disappointed to see the low interest from the market to change. So, we can offer, we can propose, but we cannot force change. oneECG is a major step forward because we are industrialized and guarantee the process to be much more automated and digitalized as we explained in our mission. However, that requires quite a number of changes for our clients and their supply chains and they don’t like it so much. BOBST should continue to accompany the industries – labels, films, folding cartons, and corrugated – to move towards novel technologies and new solutions. So, it’s a win, win, win. Another aspect of BOBST is the consciousness of the importance of packaging. Worldwide we have developed, across Asia, Europe, Africa, the Middle East, and the Americas, solutions that fulfill the local requirements, the local trends. This is very difficult to do, not simple, but I think we tried to be local, to focus on local needs, and this proximity to our clients, hopefully, makes us better competitors.

ME Printer: BOBST is a very well-known and very well-respected brand in the Middle East for decades. How important are Middle East countries for your business? Do you see reasonable growth every year for BOBST and is it good to invest in the region?

JPB: Absolutely! The Middle East is certainly one of the biggest; it is a large area – the Middle East and Africa. Africa is much more complex. We opened BOBST Nigeria two years ago but the country is difficult. We were also forced, for reasons you know, to quit Iran. Political situations in some countries make our operations very difficult, but it has had little impact. But despite the odds, we have increased resources and employed a further 10 service technicians. It is a lot of investment. We have to continue to increase the knowledge for the fourth industry’s reserves. Our investments in Africa and the Middle East are there and we’ll continue to do so.

ME Printer: You have been investing heavily in digital technology including joining forces with SEI Laser to accelerate the development of digital laser cutting solutions and for the label and packaging industry acquisition of the remaining 49.9% in Mouvent AG to reinforce the development of your printing portfolio and other investments. It seems you are investing more in this segment of printing. Do you plan to move further into the label industry and bring more equipment in collaboration with other companies as well? How important is the label as part of your whole equipment portfolio?

JPB: BOBST started quite late in the label. We have started entering the label industry with the acquisition of Gidue in 2015. It was only analog equipment. We started the journey in 2018 with Mouvent and we’re developing a digital printing engine and this will fulfill the label, film, folding carton, and corrugated industry. COVID has certainly impacted us as we introduced new technology and we are also new in this field. Clients want to travel, clients want to see the product, and now it has been 18 months. It’s difficult. We are slow due to difficulties to hire people, difficulties to travel. Long story short, narrow web presses for BOBST are a strategic investment. We want to be the number one or number two in this field, like in every other industry that we are involved. We’ve announced our collaboration with SEI Laser because we work for the full management of the production chain for labels, for narrow web, for films. We believe that these investments will bear fruit. Starting this year, we already have good momentum and for the next five years, we are on track for continued growth. Hopefully the year 2022-23 will demonstrate the success of our new products to the market.

ME Printer: Let’s talk about e-commerce. As you know, because of COVID, it’s growing dramatically. We are at this stage where consumers look to shop online. The demand for packaging tailored to the requirements of online shoppers is skyrocketing. How do you plan to tap into this lucrative market?

JPB: The vision of the industry will answer that question because we were able to deliver more equipment that is connected, which have a shorter setup time, we have answered too much lower runs because e-commerce might need more runs, and this change of habit will push everyone to invest and create tailor-made machines for e-commerce. I think we have a good product portfolio to answer those requests. I am quite confident but am not sure at which level e-commerce will stop increasing. Today e-commerce represents less than 10% of worldwide packaging needs and so even if you grow by 20%, it still represents a minority. But growth is there and the request for e-commerce is in-and-out printing for corrugated, made with fewer colors but in-and-out capabilities, with very short setup time to cater to customers on demand – some of them want delivery in a couple of hours. That’s why I go back to the vision of why it’s important to start automating and being able to ship on the truck with Twin PDF and you need to manage the operations and assets. The challenge for clients will be how you can replace these assets over the next 5 to 10 years to become as digitized as possible. This is a big challenge.

ME Printer: You have decided not to participate in physical shows and instead promote your products and services using virtual events, you have already launched a number of virtual events, do you find them effective, or still in-person meetings offer better results?

JPB: We will participate in shows but without machines. We will have what we call a “Technology Lounge.” So, we will be there present, but without machines. We all love to see machines. I am the first one. I am a mechanical engineer and so I love to see machines running. But to bring 50 or 100 tons of machines for a show for three or four days, spending so much energy is not sustainable. We have to be responsible. We cannot say “A” and do “Z.” I would like to see machines, absolutely. We are investing in our packaging centers in various areas in Europe, Asia, and the Americas for the clients to have a full vision of our industry. We will participate in fairs and exhibitions but without machines. The only regions where we will continue to have machines in are in China and South East Asia but on a much smaller scale. Yes, clients might not be so happy. The competition will play with it certainly. But we have a clear vision and I believe clients will be happy and can see the full spectrum of equipment as compared to two or three machines exhibited. In our technology centers, you can see over 100 technologies. Ultimately, future will tell us whether we are right or wrong (Laughs).

ME Printer: You mentioned China. China is becoming important to many manufacturers. Big press manufacturers shifted factories there and are investing a lot. You also have invested in China. Do you think China will become your number one client and would you see factories making BOBST machines in China?

JPB: About 10 years ago, I would have told you ‘Yes’, maybe. Today, I can say ‘No’ because China today is too much of a risk for BOBST due to political rifts and constraints with the USA and Europe. So, we need to mitigate the risk. We have facilities in China and have strong policies for China in China and this is what we want to produce in China, to fight and grow in China. But the strategy of the group is to continue to develop our production footprint in Europe and keep the one in Brazil and India. China is a very specific market we know, with huge growth, and one of our major competitors is setting up big manufacturing operations in China. But I feel this move is mostly because the bigger shareholders are Chinese.

ME Printer: You have a number of Competence Centers around the world. What role do these play in your overall strategies and will we see a Competence Center here in the Middle East, maybe in Dubai, sometime in the future?

JPB: (Laughs) I wish. Competence Center is a big investment with a lot of resources and knowledge. I don’t have the answer today as we have not decided to have a Competence Center in the Middle East, unfortunately, due to the cost. On the other hand, the Competence Centers play a major role in our strategy, as this is the pillar to demonstrate the execution of our vision. We welcome and would like journalists to participate and discover these packaging centers. In May we have one in San Giorgio, one in the US, and one in China to demonstrate the execution of our vision. This is our strategy today.

ME Printer: When I visit printers all over the Middle East, they have BOBST machines, some of them are very old. And they love it and say it works well, so why should they change it. So do you think BOBST is also a victim of its own success, at least when it comes to the small and medium printers, if not for the big ones? How can you encourage them to go for the new ones, the state-of-the-art ones? Some of them have the money to invest, but they’re happy with the old ones?

JPB: So, I guess I prefer that my main competitor is old BOBST machines rather than Chinese competitors. Secondly, the new generation will certainly understand the connectivity and importance of data, and I am sure the older machines will not be able to cope with this transformation and revolution. The solution that we bring with the DM5, if you look at this machine is really 85% fulfilling our vision and with a very competitive investment cost required. So, I believe, clients step-by-step will move into these technologies because they have to survive. They will need to have in-line shopping capabilities with their clients. The web-to-print, 10 to 12 years ago, was nothing. Today the web-to-print has a turnover of more than 500 million in Europe. New companies which did not exist yesterday are here and I am sure in your country this is the same. Another offer we are doing now is the ‘overhauling’ strategy. We just require small companies which can overhaul equipment, especially flexo, and die-cutters. That will bring new life to the machines because we overhaul the entire electrics of the equipment. So, the mechanics stay and electric parts are refurbished and customers can connect the equipment and automate with a small cost. You cannot automate a 1970s machine and its functions fully, but at least you can link these machines to the workflow, download data, and measure some points. We are offering this new channel as we understand clients may want to buy 50% new machines and 50% ‘overhaul’ equipment. That’s why we invest in this journey.

One Comment