Complete Print Inspection of Flexible Packaging

100% inline inspection increases uptime, reduces waste, and saves resources

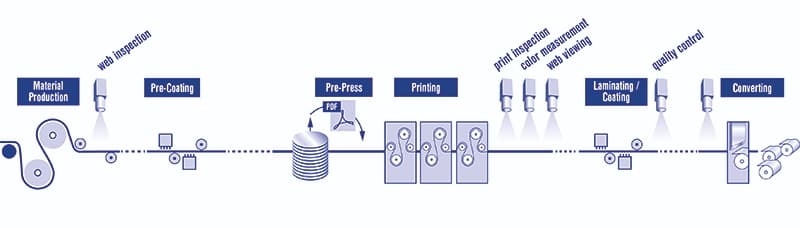

Flexible packaging is suitable for many everyday products. It protects products from external influences and does not require large amounts of material to produce while also providing an appealing appearance to attract end customers. In order to detect even minute defects and deviations as early as possible in the production process, machine operators simply cannot do without a state-of-the-art defect detection system. These systems identify quality-relevant process deviations to increase the amount of on-spec material that is produced and sold. With advanced components and intelligent image analysis solutions, ISRA VISION’s PrintSTAR inspection system identifies all typical process deviations and print defects early in the process. In addition, the unique MultiView feature reliably detects defects that are barely visible to the naked eye, including hazing, cold seal defects, and other defects that occur when applying protective and finishing coatings. Combined with the ColorSTAR module for absolute color measurements and the ViewSTAR web viewing system, ISRA VISION offers a comprehensive portfolio for 100% inspection of printed flexible packaging films during production.

Immaculate packaging without visible deviations is an important quality criterion for end customers. Besides promising a high-quality product, the packaging is also important for brand perception and hence has a positive effect on sales. To achieve competitive production of printed films for flexible packaging, the printing process has to be continuously monitored and optimized. A key challenge here is to meet these high quality requirements at maximum production speeds while simultaneously keeping waste and setup times to a minimum. Early detection of defects saves time and money:Less rework not only means less material and time required, but also increases sustainability by reducing the amount of waste produced. Ultimately, fewer valuable resources are used.

ISRA VISION has developed a complete product portfolio for printed image monitoring and print inspection to meet these high demands. At the center of this portfolio is PrintSTAR, the inline inspection system for 100% quality control using high-resolution color line scan cameras. Line scan cameras detect all typical print defects in gravure and flexo printing and, as of late, in digital printing as well. PrintSTAR also comes with additional 100% inspection modules. These MultiView features offer unique options for 100% inspection in a single system, with MultiView being able to identify issues caused by hazing on the printing machine, for example. MultiView can also be used – in addition to printing – when the machine performs applications of coatings such as cold seal, protective or finishing coatings. PrintSTAR can be combined with ViewSTAR to add high-resolution web monitoring or with ColorSTAR for absolute inline color measurements. The portfolio of PrintSTAR, ViewSTAR, and ColorSTAR offers a perfectly tailored end-to-end solution for customers, with added benefits thanks to integrated data linking and consolidation. ISRA’s condition monitoring solutions enable operators to monitor important process KPIs and, by defining customized limits, to ensure stable production processes across all work steps.

Defect-free print quality thanks to 100% web inspection

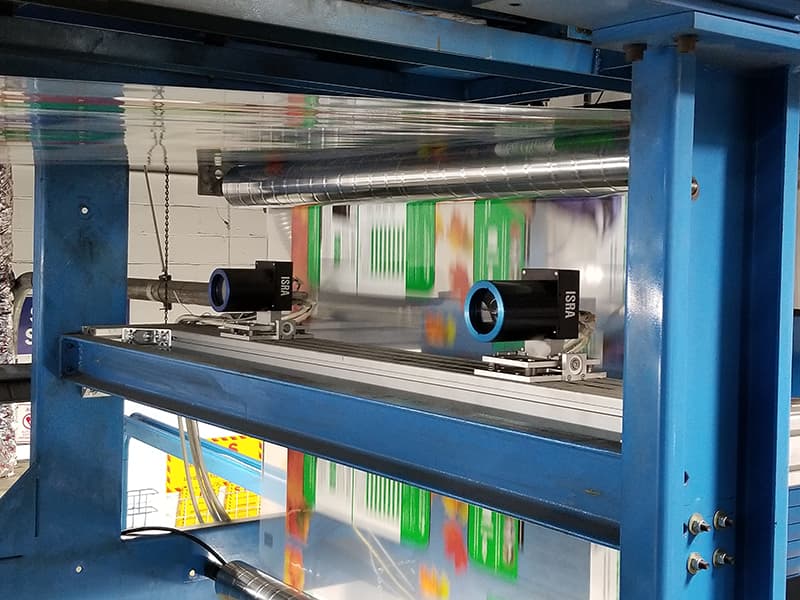

The PrintSTAR print inspection system reliably detects even the tiniest deviations in printed images – all thanks to ultrabright LED lighting, high-resolution color line scan cameras, and a powerful image processor. At the full processing speeds of the latest generation gravure and flexo printing machines, the processor analyzes the entire print repeat and identifies and classifies print deviations in real time. The system inspects printed images on web widths between 600 and 2,500 mm. If necessary, print and cold seal inspection of the backside of the film or an inspection system for special finishing effects can be integrated into the very same PrintSTAR system. Typical print defects such as blade streaks, stripes, splashes or spots, missing and incomplete prints as well as contaminations and streaks on printed films are reliably detected. Working in the background, sophisticated algorithms classify all issues found and issue alarms only for relevant defects.

An interface to ISRA VISION’s EPROMI data mining software compiles the collected data for reporting and allows for correlating it with other process data from the printing machine.

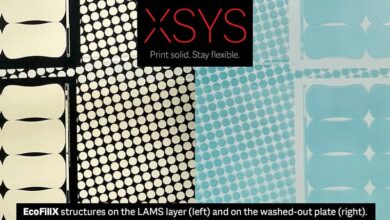

Detecting “invisible” defects

Three innovative MultiView features add additional inspection options to PrintSTAR that go far beyond conventional print image monitoring. By combining several banks of cameras, the inspection system even detects production-related defects that are invisible to the human eye. These also include cold seal defects, which are incredibly difficult to detect reliably on highly reflective surfaces, even for optical inspection systems. However, two-sided film inspection, using high-resolution LCD cameras combined with ultrabright LED lighting, not only brings cold seal defects such as contaminations to lightIt also checks register accuracy by inspecting both channels (back and front) with superimposed representation. If the sealing layer on the back does not precisely match the printed image on the front, the system issues an acoustic signal to alert operators.

Another MultiView function is the inspection of protective and finishing coatings on flexible packaging. Optical and haptic effects highlight the quality of the respective products and are often used as a distinguishing feature to help consumers find their way through today’s thicket of products. The effects range from simple embossing to gloss and soft-touch impressions, up to incorporating silver and gold pigments. To ensure that these value-adding finishing effects are completely free from defects, they can also be inspected with special, permanently installed image acquisition units.

Hazing is a defect sometimes observed on transparent substrates. This defect causes a slight and even color haze outside the image field and across the entire film. Invisible to operators, this defect is usually caused by doctor blades, cylinders, or ink. In most cases, it is only detected in subsequent processing steps or at the customer, thus causing high rework costs or even negatively affecting the supplier’s reputation. This type of defect has been almost impossible to detect until now, even with powerful inspection solutions. However, thanks to the Advanced Hazing Detection function, the PrintSTAR 100% inline inspection system is now capable of reliably detecting potential hazing defects. Highly advanced line cameras inspect the entire web during the production process in order to detect defects that are invisible to the bare eye. Operators can then implement suitable countermeasures to reduce reject rates.

Perfect color fidelity and unique image quality

High requirements are also placed on the color of products. Since colors are very important for brand recognition, consistency and compliance with minimum tolerances are of utmost importance. To ensure optimum productivity, it is necessary to inspect and document color consistency already during setup.

Color defects can quickly become an issue, because they are often very difficult to spot. Only significant color deviations can be noticed at first glance. Inline color measurements using ColorSTAR ensure complying with all color tolerances at any time while also offering an option to document color consistency. The combination of a spectrophotometer with color line scan cameras enables continuous monitoring of absolute color values and color density. The real-time measurements can always be performed and repeated on any section of the printed image, reducing setup times and offering print operators a reliable tool for checking color consistency at any time during the process. Thanks to this, operators can fully rely on perfect color results right from the very start. The complete and automatic documentation of color measurements of every printed roll provides operators with peace of mind later on and is another quality criterion for customers.

For specific tasks, machine operators rely on a high-resolution display of image details. When setting up print jobs, operators analyze register marks and color control strips with the highest resolution in order to configure the printer precisely. During production, operators monitor distinct image details that enable them to verify instantly whether their print job still meets the desired quality criteria. The ViewSTAR system for printed image monitoring offers outstanding imaging performance for evaluating the finest details on every substrate. Two Ultra HD CMOS cameras with fixed optics of different focal lengths ensure high-quality results. Since the cameras do not use zoom lenses, they capture high-resolution micro and macro images without any distortions while effectively minimizing costs for wear and spare parts. The digital LED flash ensures there is no image blurring even at maximum processing speeds. With measurement field sizes of 30 x 23 mm and 230 x 172 mm and inspection widths of 1,050 mm, 1,300 mm, and 1,650 mm, even the smallest details and individual printing dots can be identified at a resolution of 2,400 dpi. As such, ViewSTAR is ideally suited for use with all state-of-the-art flexo and gravure printing systems.

Think dual – think twice

ISRA’s new DualSTAR offers a perfect symbiosis between surface and print inspection. With a single system, operators can inspect both printed and unprinted web material – simply at the touch of a button. In addition to offering powerful performance and ease of operation, this new two-in-one solution also considerably reduces costs. From now on, operators do not need to buy two separate systems – all they need is the innovative DualSTAR system that can do both! This is an immense benefit for customers, given that they can now fully rely on ISRA as a single supplier, making installation, operator training, and adoption processes significantly easier, quicker, and more efficient. What is more, customers can save on spare parts since they only need to store components for one system instead of two. After-sales service calls are also considerably reduced compared to other suppliers. Additional unique selling points of the new DualSTAR include low calibration costs and shorter downtimes for service calls.

Summary

Thanks to ISRA’s efficient inspection solutions, material and time expenditure can be reduced along the entire printing process, making it more sustainable as a result. Users can benefit from perfectly aligned systems and modules in conjunction with additional features for specific inspection tasks that go far beyond conventional defect detection.

13 Comments