In the world of labels and packaging, the success of a print job is often decided long before the press starts running. While presses, inks, and substrates tend to take center stage, it is the pre-press output stage that quietly determines whether production will be smooth, repeatable, and profitable—or plagued by delays, waste, and inconsistency.

Pre-press output is the critical bridge between creative intent and industrial execution. It is the point at which manufacturing specifications and digital design files are translated into the physical tools that will ultimately produce the printed product. Printing plates, cylinders, screens, and tooling data are all created here, and the accuracy of this stage directly influences press efficiency, make-ready time, and final print quality.

At this stage of production, layouts are created, step-and-repeat data is generated, films may be imaged where required, and plates or cylinders are prepared for mounting on press. Equally important is the preparation and verification of embellishing and converting tools, as well as the accurate mounting of plates and sleeves. Each of these elements must work together seamlessly. Any weakness in this chain will almost certainly reveal itself later as lost time, wasted material, or compromised quality.

Consistency in output relies heavily on discipline and standardisation. A clearly defined and agreed manufacturing specification is essential, as is strict adherence to approved suppliers and materials. Deviations—whether in repro changes, die-cut profiles, print process selection, or press specification—introduce variables that are difficult to control and often expensive to correct. In a region such as the Middle East, where many converters serve demanding FMCG, pharmaceutical, and export markets, consistency is not a luxury but a requirement.

One of the most technically demanding aspects of pre-press output is the management of dot gain. Every printing process has a natural operating window where ink densities are stable, but this condition does not always deliver the tonal values required by the design. Press fingerprinting allows these characteristics to be measured, and the digital files are then adjusted before plate imaging to compensate. Without this correction, even the most advanced press cannot deliver predictable color and tone.

Print layout planning, often referred to as imposition, plays a decisive role in productivity. A well-designed layout maximises the number of impressions per press revolution while minimising substrate waste. It must also respect the mechanical and inking limitations of the press and finishing equipment. Designs that combine heavy solid areas with fine detail may require creative solutions, such as splitting color across stations or supporting solids with screen tones, to maintain stability during printing. Once the layout is finalised, the step-and-repeat data defines how many images appear across the web and around the cylinder, directly influencing output speed and cost per label.

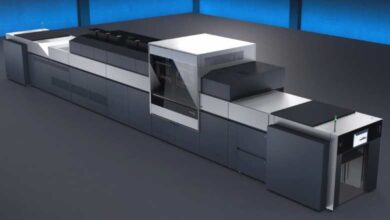

Modern pre-press workflows rely increasingly on computer-to-plate technology. By imaging digital files directly onto plates, screens, or cylinders, CtP eliminates the distortions associated with film, reduces process steps, and improves control over fine detail and dot structure. This is particularly valuable in label and packaging applications where high resolution, tight registration, and fast changeovers are essential.

Different printing processes demand different approaches to plate and cylinder preparation. Letterpress plates, typically photopolymer-based, can be produced quickly and are well suited to short-run label work, provided exposure and wash-out processes are carefully controlled. Flexographic plate technology has evolved rapidly, with direct laser imaging and high-resolution plate-making now capable of reproducing extremely fine detail and stable highlight dots. The introduction of sleeves—both photopolymer and elastomer—has further reduced mounting time and improved repeat accuracy, particularly on mid and wide web presses.

Offset lithography relies on planographic plates with a photosensitive coating on an aluminium base. While film imaging still exists, CtP has become the dominant method, offering consistent results and simplified processing. Screen printing, whether flatbed or rotary, remains essential for high ink laydown and special effects. Laser-engraved screens have significantly reduced preparation time and improved repeatability, making screen printing more compatible with modern, fast-paced production environments.

Gravure occupies a unique position in packaging printing. With ink volume determined by engraved cell depth rather than press settings, consistency is built into the cylinder itself. Advances in laser engraving and digital control have made gravure cylinder production more accurate and repeatable, while the ability to strip and reuse cylinders improves long-term cost efficiency.

Once plates and cylinders are produced, mounting becomes the next critical control point. Plates must be positioned correctly on the first attempt, as removal and repositioning—particularly with flexible plates—can introduce stretch and register errors. Mounting tapes, often overlooked, vary in thickness and compressibility and must be accounted for when calculating final cylinder dimensions. Even minor deviations can prevent accurate registration across multiple colors.

Mechanical condition is equally important. Bearings, gears, anilox rollers, and print cylinders must operate within tight tolerances. In flexo, letterpress, and litho printing, print cylinders should run with minimal deviation to maintain constant pressure and register. Gear-driven systems require precise meshing at the correct pitch diameter, while modern gearless presses with servo drives offer improved accuracy and reduced setup times.

Despite all the precision built into pre-press output, printing remains a dynamic process. Skilled operators play a crucial role in fine-tuning ink formulations, viscosities, pressures, and damping levels to maintain consistency throughout a run. Each print process—letterpress, flexo, litho, screen, or gravure—offers its own set of controls, but all depend on a solid pre-press foundation.

For converters in the Middle East, where competition is intensifying and customers demand shorter runs, faster turnaround, and consistent quality, pre-press output is no longer a back-office function. It is a strategic capability. When executed correctly, it reduces waste, shortens make-ready times, improves press utilisation, and ultimately protects margins.

In today’s label and packaging market, excellence on press begins long before ink touches substrate. It begins in pre-press output—where precision, planning, and process discipline quietly set the stage for success.