HEIDELBERG Celebrates 175 Years of Innovation & Excellence

On March 11, 1850 – exactly 175 years ago – the Hemmer, Hamm & Co. bell foundry and machine shop opened in Frankenthal, a town in southwestern Germany. Besides bells, it also made printing presses, which laid the foundations for the company now called Heidelberger Druckmaschinen AG (HEIDELBERG). Precision, quality, and innovation were the success factors that transformed HEIDELBERG from a workshop based in the Palatinate region to a global player in the printing industry.

“A company that can sustain its success over such a long period, become a world leader in its industry, and continue to shape the entire sector right up to the present day has strong credentials that are testament to its innovative capabilities. The defining feature of HEIDELBERG is the company’s understanding of markets, customers, and exceptional product quality,” says CEO Jürgen Otto. “We also intend to maintain and build on this leading position in the future,” he adds.

Tapping Growth Potential in Core Business

To achieve this, HEIDELBERG is tapping into growth potential in its traditional core business – from packaging and digital printing to software and lifecycle products. Recently, the company has significantly expanded its portfolio in the growth market of industrial digital printing, including service and consumables. Global incoming orders confirm that sales of digital printing solutions will already start increasing substantially from the coming financial year. According to market assessments, the global digital printing market that is accessible to HEIDELBERG will grow from its current level of around 5 billion euros to 7.5 billion euros in 2029.

As for lifecycle business, HEIDELBERG boasts the industry’s most comprehensive service network, with a presence in approximately 170 countries.

Packaging Printing Enjoys Robust Growth Worldwide

The end-customer market for packaging has grown by more than 60% over the past ten years. HEIDELBERG, too, is benefiting from this development. The packaging segment accounts for more than 50% of the company’s sales, a figure that is set to increase further still. One market driver is the global trend toward replacing plastics, films, and foils with recyclable fibre-based packaging.

Hybrid Print Production Boosts Competitiveness

Autonomous printing processes that make printing businesses more efficient and save on resources used to be regarded as a futuristic vision, but that changed some time ago. HEIDELBERG introduced its Push to Stop concept for a printing process with minimal operator intervention back in 2016. The AI-assisted Prinect Touch Free workflow showcased at drupa 2024 assigns print jobs to the most efficient production method and output system on an automated basis. Besides offset and digital systems from HEIDELBERG and third-party suppliers, it also covers postpress operations, all the way through to the finished final product. Controlling hybrid print production in this way makes print shops much more competitive.

Portfolio Expansion for Industrial Business, Green Technologies Market

“In addition to this, we will be further expanding our portfolio for industrial business and the growing green technologies market. This includes key sectors such as high-precision mechanical engineering, the automotive industry, charging infrastructure, software, and new hydrogen technologies,” reveals Otto. Taking into account all strategic initiatives in the period leading to the financial year 2028-29, and in conjunction with enhanced performance and efficiency at both staff and organisational levels, HEIDELBERG sees overall growth potential amounting to over 300 million euros. “The achievements of HEIDELBERG over the past 175 years are impressive. We have every reason to be confident that our current market position, the expertise of our staff, and our global customer relationships will deliver further growth in the coming years,” emphasises Otto.

Year-long Activities to Mark Landmark Anniversary

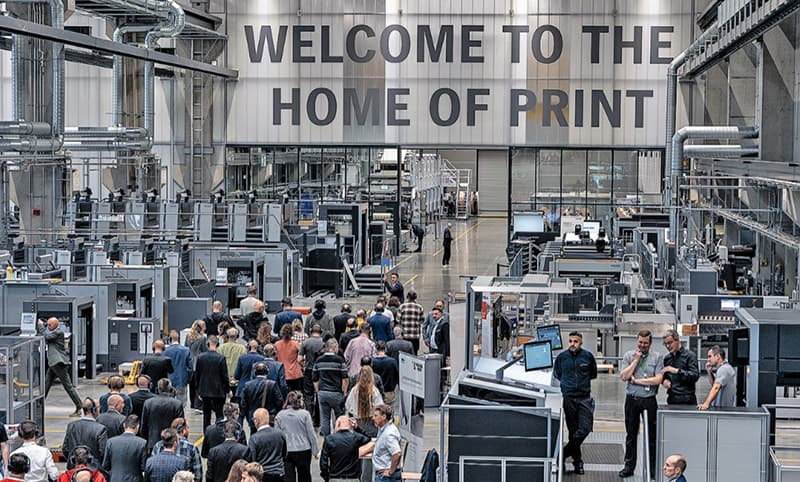

Numerous events have been planned as part of the 175th anniversary celebrations that will include customers, partners, politicians, and representatives of civil society. The highlight will be a week of celebrations in June at the Wiesloch-Walldorf headquarters’ newly designed customer demonstration centre – the Home of Print.

Family days are planned for employees at various sites. HEIDELBERG is also publishing an anniversary magazine providing insights into the company’s past, present, and future. “The loyalty of HEIDELBERG customers, partners, and staff is a mainstay of the company’s success. The numerous anniversary activities throughout the year are our way of saying thank you to everyone. At the same time, we want to encourage a shared commitment to shaping the future,” says Chief Technology & Sales Officer Dr. David Schmedding.

Milestones

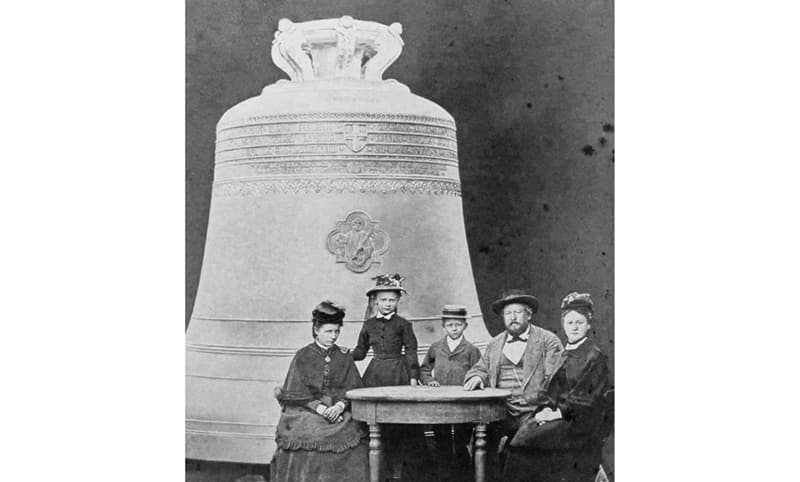

1850: The Hemmer, Hamm & Co. bell foundry and machine shop opens in Frankenthal on 11 March, laying the foundations for the company now called Heidelberger Druckmaschinen AG.

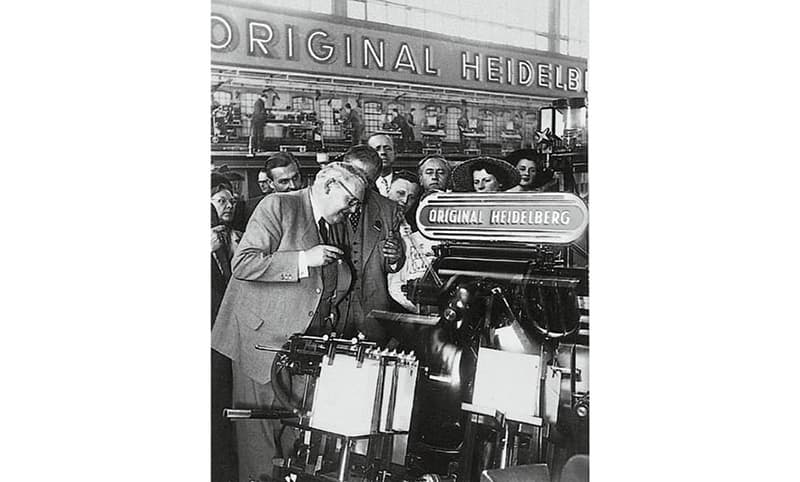

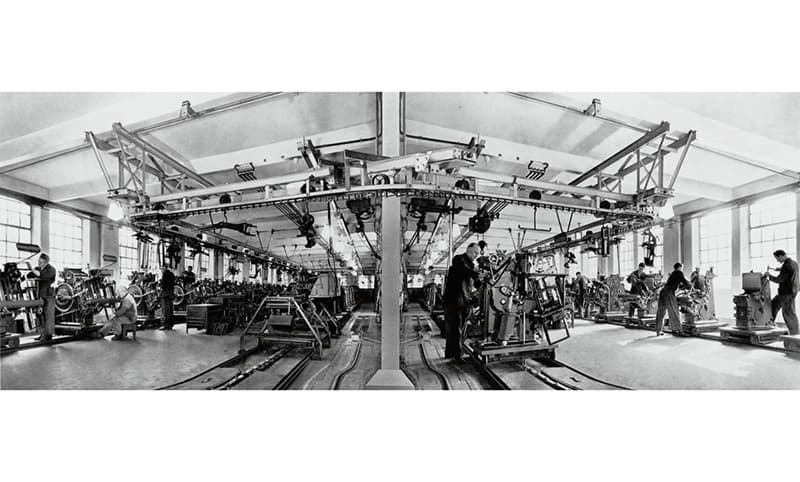

1921: The first Heidelberger Tiegel is built. From 1926 onward, this automatic letterpress platen press was produced on an assembly line and by 1985 over 1,60,000 units were manufactured.

1926: Hubert H. A. Sternberg is appointed to the board of Schnellpressen-fabrik Heidelberg AG, as the company was known at the time. He remained a board member until 1972, making a significant mark on HEIDELBERG. Sternberg modernised production and marketing operations and ensured the company’s growth. In 1949, he organised the first German export exhibition in the USA after the Second World War. In 1951, he then helped initiate drupa, the sector’s leading global trade show to this day.

1930: Demo vehicles were set rolling. One of Sternberg’s marketing ideas was to demonstrate HEIDELBERG presses to potential customers at their premises. This involved assembling them on trucks or installing them in buses and sending them to target markets around the world, accompanied by engineers. Advertising campaigns and installment-based payment plans also contributed to the marketing success.

1951: drupa proves to be a huge hit, attracting 3,00,000 visitors in its first year. HEIDELBERG presented an enhanced version of its successful Tiegel model. As a protection, all the company’s presses had the manufacturer’s plate bearing the “Original Heidelberg” trademark.

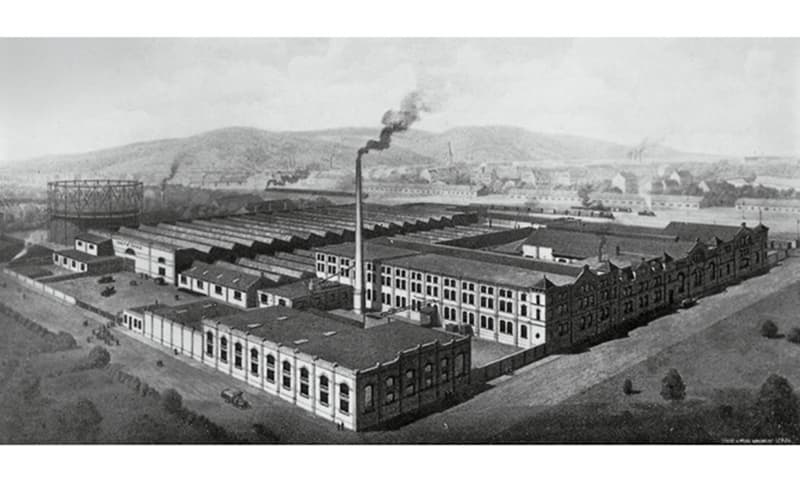

1957: HEIDELBERG creates space to grow. As further expansion within the city of Heidelberg was impossible, Sternberg’s strong commitment led to the establishment of what is still the company’s largest production site in Wiesloch-Walldorf in just a year’s time.

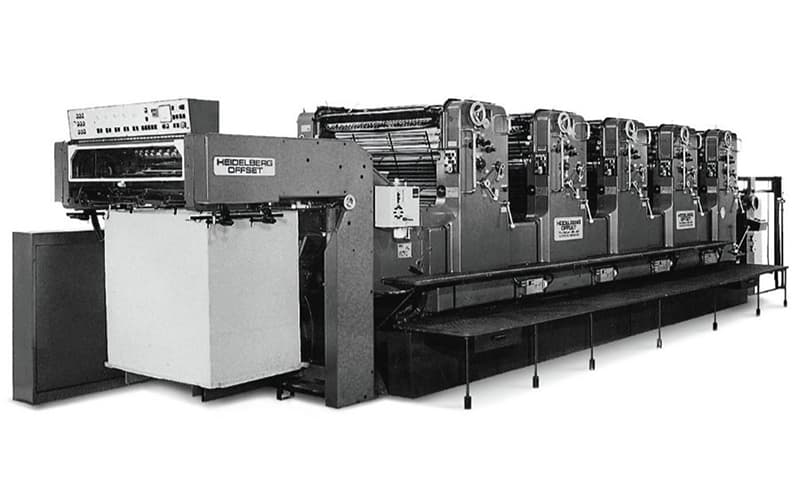

1962: HEIDELBERG moves into the up-and-coming offset market with its small offset rotation press (in German: Kleine Offset Rotation, or KOR for short). In 1965, this was followed by the Rotaspeed, a larger sheetfed offset press. In 1972, a large platen offset press (in German: Grosse Tiegel Offset, or GTO for short) was launched and proved a successful model for years to come.

1975: The Speedmaster sheetfed offset press for multicolour printing revolutionised the market with its productivity. Operating at 11,000 sheets per hour, it became a bestseller and is, to this day, a cornerstone of the HEIDELBERG portfolio in its traditional core business.

1999: HEIDELBERG acquires 30% percent stake in Swiss press manufacturer Gallus, a market leader in label printing, before taking over the company completely in 2014.

2000: HEIDELBERG transforms itself into a solution provider, expanding its prepress and postpress portfolios through targeted acquisitions. Prinect software ushers in the era of digitalisation by networking various machines in the workflow.

2004: HEIDELBERG takes a further key step toward digitalisation by connecting a press to the internet for the first time.

2005: Production site opens in Qingpu Industrial Zone, Shanghai. The Chinese plant is today a cornerstone of the company’s production network.

2016: At drupa, HEIDELBERG introduces Push to Stop as the next step towards autonomous printing.

2018: Wallbox production starts in Wiesloch-Walldorf. The company subsequently founded a subsidiary called Amperfied that successfully tapped into a new area of business – the electromobility market.

2020: Moves into robotics, with industrial robots driving automation of the printing process, including postpress operations, and will extend to other areas in the future.

2024: The new Jetfire 50 digital press developed in cooperation with Canon is unveiled at drupa 2024, offering industrial productivity in the growth area of digital printing.

2025: Celebrating 175 years. Opens its redesigned customer demonstration centre – the Home of Print – in Wiesloch-Walldorf. Charts out a clear growth strategy for the future.