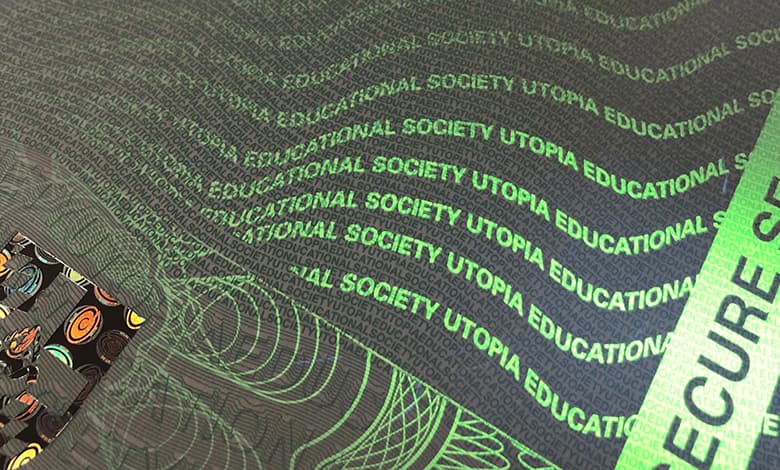

Advanced Inks and Coatings for Product Security

To safeguard products from counterfeiting, tampering, and to authenticate them, a wide array of advanced security inks and coatings can be employed. These solutions serve as critical tools in protecting brands across various industries, offering both visible and concealed methods of validation. From simple, overt systems to highly specialized covert mechanisms, these technologies play an essential role in securing products on shelves, in warehouses, and even in forensic laboratories.

Overt or Primary Validation

Overt security features provide immediate, visible confirmation of a product’s authenticity, often allowing verification within seconds. These types of systems are particularly useful for frontline inspections by consumers, retailers, or customs officials. Some common examples include:

- Matte or Gloss Varnishes: One of the simplest forms of overt protection is using matte or gloss varnish coatings, which prevent the reproduction of products via photocopiers. Adding color-shifting pigments to these varnishes further increases the difficulty of replication.

- Optically Variable Inks (OVI): These inks change color when viewed from different angles under light. They require print processes that can handle heavier ink weights, such as silk screen printing. Iridescent inks, a subset of OVI, offer a lower level of protection but still present a visual deterrent to counterfeiters.

- Thermochromic Inks: These inks change color permanently when exposed to certain temperature conditions, making them ideal for products that need to be stored or transported within specific temperature ranges. Tri-thermochromatic inks can change through multiple colors depending on the temperature profile, which can be tuned to provide specific visual indicators of mishandling in the supply chain. These inks are especially useful for pharmaceuticals and perishable goods, where temperature excursions can degrade product quality.

- Coin Reactive Coatings: A simple yet effective anti-counterfeit measure, these coatings are made from semi-gloss varnish that turns gray when rubbed with the edge of a coin, a reaction caused by the oxidation elements in the coating.

- Penetrating Inks: Designed to infiltrate paper substrates, these inks bleed through the paper and reveal a security message when viewed from the reverse side. Because the ink is absorbed into the paper fibers, this method is extremely secure and difficult to counterfeit, as it cannot be simply removed or altered without destroying the substrate.

Covert Inks and Hidden Authentication Systems

Covert security inks provide a hidden layer of protection that can only be authenticated using special instruments such as ultraviolet (UV) lights, laser scanners, or even smartphones. These systems are often used alongside overt features for multi-layered security. Some common covert inks include:

- UV Responsive Inks: Also referred to as “black light” inks, these inks become visible when exposed to ultraviolet light. They can be tuned to specific UV wavelengths for added security, ensuring that only authorized personnel with the correct light source can verify the feature.

- Phosphorescent Inks: These luminescent inks continue to glow even after the UV light source has been removed. The duration of the glow can be precisely measured, offering an additional layer of authentication that is difficult to replicate.

- Metameric Inks: These inks change color when viewed under different types of light sources, such as daylight or fluorescent lighting. This allows a different image or security feature to be revealed depending on the lighting conditions.

- Photochromic Inks: These inks change color when exposed to natural or artificial light. However, prolonged exposure to sunlight can cause the color to fade over time, making them more suitable for temporary authentication in controlled environments.

- Conductive Inks: Allow packaging or labels to interface directly with smartphones. When the label is touched to the phone screen, it connects the user to a secure website for online authentication. This digital layer of security adds an interactive and verifiable experience for consumers, enabling real-time validation of the product’s authenticity.

- Machine-readable Inks: This category of inks includes materials detectable by specialized scanners that read specific chemical signatures. Typically formulated with rare earth elements, these inks emit a unique signal under near-infrared light, which can be read by handheld devices or industrial-scale conveyor belt systems for bulk product verification. These inks are ideal for high-volume industries where rapid, automated authentication is required.

Tamper Evident and Forensic Inks

In addition to standard covert and overt systems, more advanced inks can also help prevent tampering and provide forensic-level authentication, further bolstering a product’s defense against counterfeiting or alterations:

- Tamper Evident Inks: These inks are designed to protect against attempts to alter or erase critical information, such as expiration dates or serial numbers. A layer of erasable ink is printed beneath the main code, often combined with chemically sensitive ink that changes color if attacked by bleach or other corrosive chemicals, making any tampering attempts immediately visible.

- Forensic Inks: Offering the highest level of security, forensic inks contain microscopic particles that require advanced laboratory equipment to detect and authenticate. These particles may include synthetic DNA, microtaggants, or other unique identifiers that are nearly impossible to duplicate. Organic markers such as synthetic DNA can be applied through inkjet printing, while inorganic markers, like doped crystals, are best used in more viscous inks or varnishes. These features are used in high-security applications, such as currency protection, passports, or high-value branded goods, where counterfeiting risks are severe.

Practical Applications

Security inks and coatings are used in a variety of industries to protect against counterfeiting, tampering, and unauthorized alterations. From pharmaceuticals and cosmetics to luxury goods and currency, the implementation of these technologies is crucial in maintaining brand integrity and consumer trust. Whether applied overtly for easy verification or covertly for expert validation, these advanced security features ensure that products remain authentic throughout the supply chain, from production to the end consumer.

For further insights into the evolving field of product security, refer to specialized resources on brand protection, security labeling, and packaging solutions. These systems are continually advancing to meet the growing challenges posed by counterfeiters in an increasingly globalized marketplace.