Workflow Automation Brings Finishing Fully Into the Realm of Digital Production

Ayman Ali, the Senior Marketing Manager for B2B at Canon Middle East, speaks about why finishing forms a major part of the print industry

What sort of technology and market trends do you see in the print finishing industry?

According to a Smithers Pira study titled ‘The Future of Print Finishing Markets to 2023’, in 2018 the global market for new post-press equipment was $4.87 billion, a little down from the high of $5.10 billion in 2013. The market is expected to rebound slightly across the next five years to reach $4.90 billion in 2023.

This situation will be addressed by the expanding demand for digital print finishing equipment. Innovation in the print finishing market is driven by the attempt to make print more appealing to consumers and to add value to the final product with impact finishing. This includes integrating embossing, digital post-press enhancements, laser cutting, among others, into machinery for label finishing, packaging, and commercial print.

How can adding digital finishing into their workflows help printers?

Today, finishing can be fully integrated with prepress and printing in a workflow based on relaying digital job specifications from process to process. When this happens, the whole print manufacturing paradigm changes. Postpress traditionally has been the most labor-intensive stage of print production while digital finishing, especially when it takes place in-line with the press, breaks the bottleneck by eliminating the gaps that tend to isolate process steps in a conventional bindery.

Workflow automation is what brings finishing fully into the realm of digital production. It is especially critical in jobs containing variably printed elements or multiple components—for example, book blocks with tabbed inserts and covers—that have to be brought rapidly and precisely together. Canon’s PRISMA production management software is an adaptive workflow solution that lets Canon and Océ presses work seamlessly with equipment from the leading providers of digital finishing systems. Together, the software and the devices represent digitally integrated manufacturing at its most efficient—with finishing as the most efficient step of all.

What sort of products and solutions in terms of print finishing, do you offer on the market?

Canon offers a variety of in-line finishing solution that is fully integrated with the digital press. These in-line finishing options include perfect binding, stackers, hole punchers, booklet makers with a three-way trimmer, and more. These professional feeders and finishing solutions aim to provide for perfect results every time.

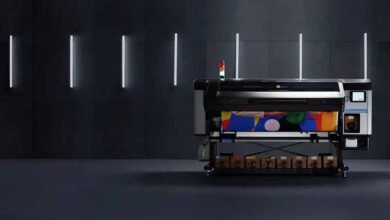

The Océ ColorStream 6000 Chroma is a highly versatile inkjet web press combining outstanding quality and flexibility for the efficient and reliable production of mail, publishing, and commercial applications. United Printing and Publishing (UPP) in Abu Dhabi, recently added the region’s first Océ ColorStream 6000 Chroma continuous feed inkjet press technology to its robust print production environment.

With the new press, UPP will have increased system versatility to extend the spectrum of applications they are able to produce digitally with the additional benefits of exceptional quality, enhanced productivity, as well as low paper waste and efficient ink and power consumption. The combination demonstrates that the best solutions come from partnerships between digital press manufacturers and qualified suppliers of digital finishing equipment.

How have print finishing technologies evolved over the years?

Today, finishing can be fully integrated with prepress and printing in a workflow based on relaying digital job specifications from process to process. Instead of prepping a job in one location, printing it in another, and binding it somewhere else, everything takes place in a unitary production line consisting of a networked press with finishing modules connected directly to it. In this in-line digital finishing scenario, the sequence is “white paper in, sellable product out”: printed, trimmed, folded, bound, and ready to ship to the customer in one pass, all from what is essentially one device.

Since print has commoditized itself, do you believe the use of different finishing technologies can be a differentiator to move away from the norm?

In areas like packaging and interior design, creative design that can utilize special printing techniques, enabled by digital press capabilities and combining different finishing options, can provide a customer with a unique customized product. This adds value to the product itself where a unique piece of decoration targets the high-value niche customer.

Digital finishing holds great promise and many benefits. As such, how can printers and production houses demonstrate the value of these special effects?

It is important to have digital printing technology which is compatible with off-line and near-line systems finishing equipment especially regarding coating or spot coating that presents the final output with offset-like quality. On the other hand, in-line finishing options provide for minimum human intervention, therefore, enabling higher productivity while also offering variety, catering to the most required printing applications like books, magazines, flyers, training material, direct mail, and the likes.

This with the additional benefit of print on demand, shorter runs, personalization, and customization capabilities, offer a comprehensive solution to the customer. Digital presses produce the best results when they are supported by digital finishing equipment. Today, a shop can have whatever digital-friendly postpress capabilities its workload requires—not just machinery, but workflow software and DFEs (digital front ends) as well.

The right capabilities to have are the ones that best suit the kinds of work a shop most commonly does. A big advantage of in-line finishing in this regard is that postpress modules can be added when new kinds of work come in. As the applications become more specialized, the production platform can evolve to keep up with them.

While many digital press manufacturers have improved processes, industry experts still feel that finishing remains a challenge. Is this statement true? If yes, what are you doing about it? If no, why?

The three areas of the printing process – prepress, press, and post-press – are continually evolving. Finishing manufacturers are developing either in-line or off-line finishing equipment that is compatible with the printing technology evolution to ensure that dynamic customer printing applications demands are met. Canon is committed to investing in strategic partnerships with different brands to develop a variety of in-line finishing options that could support customer production in-house in maintaining high printing quality, automation and cost efficiency.