Yoda and Batman are Just a Print Away at Home

A toy has always been a child’s best friend, and over the years they have developed from a mere amusement tool into a plaything that mould’s their creativity and flexibility, both, in thoughts and actions. Needless to say, toy manufacturing in the present day is a huge and lucrative global business with no dearth in ideas or innovative concepts.

3D printed toys have become a huge hit as a family-friendly activity, where even adults get a chance to enjoy making their own 3D printed action heroes, figurines, and miniatures.

Materials such as color-changing, PLA, and PETG filaments; glow in the dark; magnetic; nylon; TPE; and TPU, give children safe and varied options for limitless creativity.

The impact is so huge that even big players like Warner Bros. and Mattel have given AM companies the green signal to produce their toys and characters.

Toronto-headquartered Little You allows children to make fully customizable, 3D printed toys right through their website, letting the young minds to take advantage of 3D printing’s benefits to unleash their own creativity. Unique, custom anime figures can now be 3D printed and delivered to their door.

Christina Guo, founder of the digital platform speaks of how children in the 6 to 18 age bracket can design, personalize, and create custom characters of their choice, be they in appearance, colour, size, etc. “Little You brings 3D models to life with 3D printing. We ensure that our products are of the finest quality by working with industrial printers who guarantee the print quality.” The company’s website also provides an option to purchase and download 3D models which can be printed at home.

“As an artist, I believe in the importance of creativity and seeing the world through the eyes of a child, providing them with countless opportunities to acquire social skills while bringing families closer together,” she adds.

Boston-based Rize, a company on a mission to bring 3D printing to consumers everywhere, has partnered with the Canadian toy platform offering a range of materials that are durable, environmentally-friendly, and recyclable, with its XRIZE full-colour 3D printing technology able to unleash creativity in children of all ages.

Many individuals too are stepping up, using 3D printing to create toys. Assistant professor of computer and cyber sciences Tyler Flaagan at Dakota State University (DSU), USA, used his two 3D printers to make 23 toy train engines to donate to the nearest Toys for Tots shipping hub. Ohio-based digital 3D printing company IC3D Industries produced toys for Toys for Tots, a US Marine Corps Reserve programme for America’s less fortunate children.

British company MyMiniFactory has collaborated with 3D designers and with over one million vetted 3D STL printing files available for download primarily aimed at servicing consumers interested in gaming, cosplay, and general interest.

French 3D printers Dagoma with its initiative called Toy Rescue reduces throw away toys using additive manufacturing to fix the broken or missing parts, be it an ‘arm’ or a ‘leg.’

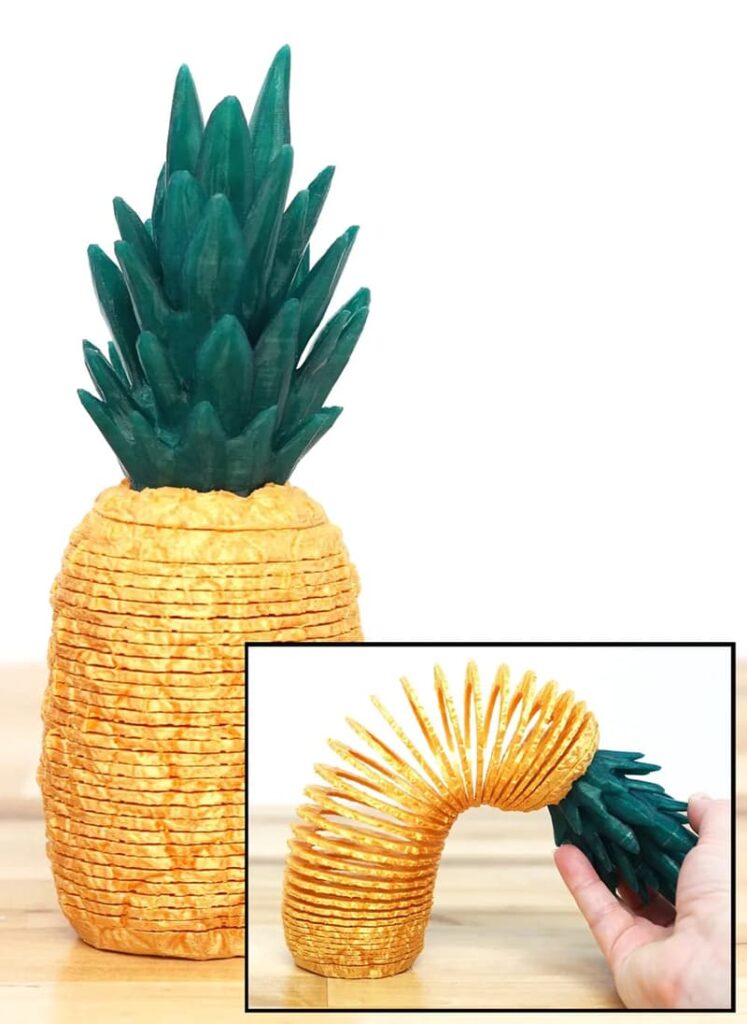

Amongst the entire gamut, some of the best curated 3D models include collapsing toy swords with a collapsible tube for the blade, 3D printable pineapple springo, the super adorable cute mini octopus, and the famous Star Wars character Yoda.

With technology advancing by the year, it comes as no surprise that the toy industry has made use of the growing popularity of additive manufacturing to create and put to shape some unimaginable toyshop ideas, and paving a path for the younger minds to think and create.