Saudi’s ALYAUM Invests in HEIDELBERG for In-mould Labels

Labels are increasingly becoming brand ambassadors, as information providers, advertising medium, and basis for innovative security features. The explosive growth in e-commerce has also significantly increased the demand for packaging labels.

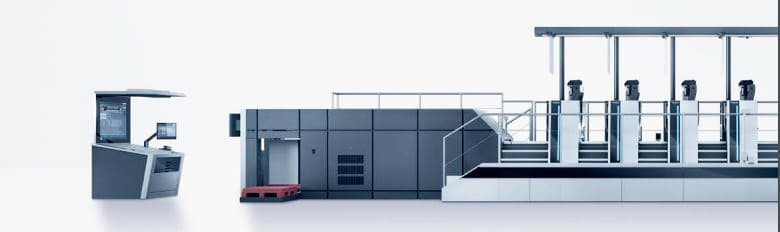

To keep up with the expanding market, Dammam-based ALYAUM media house has invested in two HEIDELBERG 8-colour Speedmaster XL 106 machines for producing offset in-mould labels (IML). The installation was closely monitored and supported by Jeddah-based Juffali Printing Systems, distributors of HEIDELBERG products in Saudi Arabia.

ALYAUM’s decision to invest in HEIDELBERG – which is by far the market leader in IML worldwide – comes after a comprehensive market research, backed with feasibility and technical studies.

The new generation Speedmaster XL 106 gives consistent results, even with challenging finished labels, thin substrates, and innovative security features. The machine also combines automation with precision, offering a coordinated portfolio for efficient production along the entire process chain. With high production speeds of up to 21,000 sheets per hour with low waste and the use of AI and digital assistants, the Speedmaster XL 106 reduces set-up and makeready times and downtimes, producing high quality at low cost per sheet.

The machine’s special IML Performance Package 4.0 is perfect for lightweight in-mould labels that place particular demands on statistics and sheet travel. In conjunction with the fourth-generation CutStar reel sheeter, even extremely thin films can be processed reliably.

The production line also includes the Speedmaster XL 106-D rotary die cutter and the Kawahara TXS-1100 blanking system. The Speedmaster XL 106-D is a compact single-unit die cutter ideal for the economical production of in-mould labels. Even complex and large labels from extremely thin materials can be die-cut with precision. The rotary die-cutter not only transfers the production speeds and quality of the press to the finishing department, it can also be connected directly to the CutStar reel sheeter with integrated register cut for processing pre-printed rolls.

The easy-to-use Kawahara TXS-1100 is an entry level machine for the label and folding carton postpress, combining high blanking quality and productivity with maximum flexibility for a wide range of blank shapes. With its wide range of materials, it addresses both in-mould label printers and folding carton printers.