PlotFactory Opts for Zünd Digital Cutting Systems

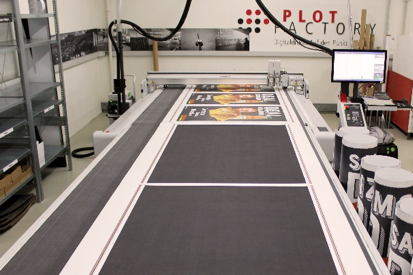

PlotFactory AG employs state-of-the-art equipment, along with a big helping of passion, to create a wide range of advertising and promotional products. Equally diverse is the range of materials that are processed with the help of Zünd cutting technologies. Since fall 2017, the company’s latest flagship digital cutter, the Zünd G3 3XL-3200, has been operating nonstop.

When Rinaldo Fochetti made the decision in 1999 to take the leap into independence by founding the PlotFactory, the one-man operation was a “factory” in name only. Barely 20 years later, things are very different even though the same pioneering spirit is still palpable in PlotFactory’s vast production halls in Weisslingen near Zürich, Switzerland.

From the very beginning, Fochetti was fascinated with the potential of digital cutting and finishing and the creative diversity these technologies offer, “We are producing an incredible bandwidth of experience-based communication, which continually demands new solutions. The approach keeps changing, and the way we use technology evolves accordingly.”

The trend towards industrial fabrication is most apparent in the high level of productivity the company has managed to achieve. Long gone are the days when printers printed at a leisurely pace, the fabric was manually cut with hot knives, and material distortions had to be corrected manually. It did not take long for order volumes and quantities to start growing rapidly.

“It became very clear that we needed to optimize our production processes, increase output quality, and lower costs. In short order, the production line grew to twelve digital printing systems and two high-performance Zünd cutters. Being able to permanently increase efficiency is game-changing in this market. With pricing structures the way they are, you don’t stand a chance otherwise,” said Fochetti.

Despite its name, PlotFactory is by no means a “factory” operation that produces the same widget all day long. Every order is different and order quantities, too, can vary greatly from one piece to many thousands. The production workflow varies with each job and may involve different departments every time. PlotFactory is geared towards versatility and has the capabilities to handle the entire value chain in-house, from prepress to printing and digital cutting all the way to a design and finishing studio, a sewing operation, and a specialty projects workshop. The latter works with materials such as acrylics, wood, and aluminum.

Postprocessing and finishing have been growing steadily for the past several years. The demand for printing as a standalone process has gone down, which is why diverse, efficient finishing capabilities are making all the difference. Being able to produce everything in-house offers tremendous advantages and thrilling possibilities. While it makes our production workflows more complex, it also increases their efficiency since we are not depending on outside service providers.

For digital cutting, PlotFactory has been relying on extraordinarily versatile and innovative Zünd digital cutting systems for many years. Besides their G3 L-3200 (180cm / 71in wide), the company has had a (321cm / 126 in wide) G3 3XL-3200 in operation since October 2017. For processing rigid substrates such as acrylics and wood, Plotfactory uses the new high-performance RM-L routing system, which delivers up to 3.6kW of power, and is equipped with the ARC automatic tool/bit changer. Stefan Herber, who is in charge of sewing and finishing operations, regularly runs the cutters himself. He is thrilled with their performance and versatility: «We are able to cut just about any material we can think of with our Zünds. It always amazes me to see just how versatile these cutters are. And it’s a great feeling to be able to live up to our motto “No-go is a no-no”.

The Zünd cutters are so productive, they cut faster than his colleagues are able to print. And tandem operation further boosts productivity: Being able to produce literally nonstop is absolutely genius. Alternating sides for loading materials, while cutting continues on the other, has dramatically sped up our production. And operating the cutter is so simple, even our interns can do it.

For Herber the user interface and workflow software Zünd Cut Center ZCC is just as important as the hardware: “I can see exactly how much time the cutter is expected to take to process a job, and after it’s done, how long it actually took. Our day-to-day operations are hectic, and many orders come in on short notice with delivery times that tend to be very short as well. So it is not uncommon for us to have to interrupt a lengthy job with a rush order. Fortunately, on a Zünd cutting system, this is easily done since so little time is required for changeovers.”

After six months, Rinaldo Fochetti’s opinion of the latest Zünd cutter installed at Plotfactory is a very positive one: “We are extremely satisfied with the new cutting system. It has given us some much-needed capacity for whenever the other Zünd is occupied, and with both machines equally equipped for cutting and routing, we have gained a great deal of production flexibility. It has given us a lot more wiggle room in production planning and order processing.”

However, it is not the cutting technology alone that makes Zünd cutters so good, concludes Fochetti: “Zünd cutters are also extremely user-friendly and reliable — simply put, they are quality products. And the same quality attribute also applies to the installation, service, and support Zünd provides. Unobtrusive, fast, diligent, and precise. It’s quite a remarkable performance, the way Zünd does it all!”