Renovations at the Windmöller & Hölscher (W&H) Technology Center in Lengerich, Germany, have been completed, and included moving their in-house prepress technology – a KODAK FLEXCEL NX Ultra Solution from Miraclon – to a brand-new plate room for quicker and easier accessibility. Providing a fast and solvent-free and VOC-free option to predictable, consistent and top-quality flexographic plates, the FLEXCEL NX Ultra Solution is used at W&H for a broad range of applications, including platemaking for press demonstrations and printing tests, as well as customer events.

“We really value our partnership with the team at W&H, who share a similar vision about where the flexo industry is moving to”, says Grant Blewett, Chief Commercial Officer at Miraclon. “Since the equipment has been installed in 2019, it has worked virtually uninterrupted for demonstrations and application development tests. We look forward to seeing more customers face-to-face again in the near future to showcase the capabilities of FLEXCEL NX Solutions on W&H’s state-of-the-art flexo presses.”

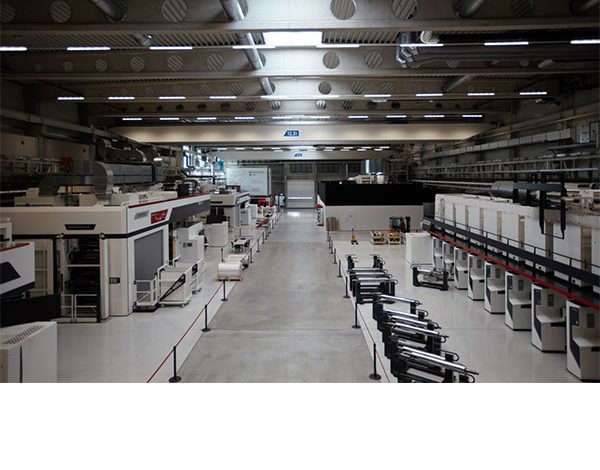

Ulrich Harte, W&H Product Management, adds: “Our 10,000 square-meter Technology Center is the largest of its kind anywhere in the world and it’s equipped with cutting-edge technologies. We can demonstrate the entire packaging printing value chain including prepress here in one place to existing and potential customers in a live atmosphere that is closely aligned to practical needs. The availability of innovative technologies like Miraclon’s FLEXCEL NX Ultra Solution is crucial to our ability to present high quality flexo packaging printing as an efficient end-to-end process.”

132 Comments