Hopkins Printing Invests in Heidelberg’s SystemService Performance Plus Package

Performance Plus program meets the growing demand within the print media industry to increase efficiencies and lower operating costs.

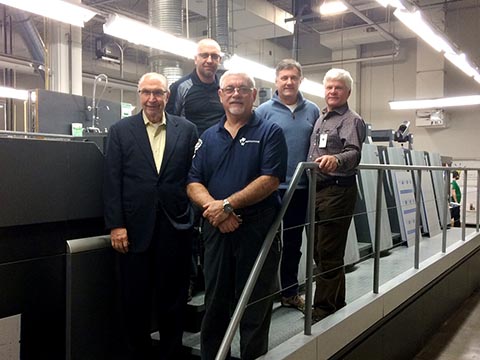

Hopkins Printing of Columbus, Ohio, has seen significant savings since implementing Heidelberg’s “Performance Plus Program,” which executes actionable recommendations through a detailed press room evaluation. Hopkins Printing decided to purchase Performance Plus to better ensure that their Speedmaster XL 106-5+L and Speedmaster XL 105-6+L are always running at peak productivity and contribute to the continued growth of the company.

Performance Plus program meets the growing demand within the print media industry to increase efficiencies and lower operating costs. The results-driven program uses a partnership with individual print shops as the key to success — meaning Hopkins Printing receives personalized and valuable insight on how their presses are impacting the company.

Through Performance Plus, Hopkins is able to track their machine data for their two Speedmasters. Heidelberg uses 3 steps to impact the company’s business: on-site pressroom evaluation, determining current productivity levels and setting specific future efficiency and cost-saving goals, and implementing the project plan. Through these steps, Hopkins has so far greatly increased the efficiency of its pressroom.

“Each month, we meet with our Heidelberg Consulting expert to discuss how our presses are doing,” said Jim Hopkins, CEO of Hopkins Printing. “The session only lasts about 20-30 minutes, but we leave knowing how our presses are operating overall. We’re able to leave confidently knowing that our presses are running efficiently and our business is growing.”

“They are engaged and open to recommendations. This is how they were able to achieve such outstanding results,” said Dave Troublefield and John O’Donnell, Consulting Team from Heidelberg. “Jim Hopkins’ team is excellent to work with. They understand the importance of data and how it affects their business.”

Within 6 months, both Speedmasters have dramatically increased productivity and efficiency. On both machines, Hopkins has doubled their net output, decreased makeready times by over 6 minutes per job, and now has a run waste of less than 1.5% percent. As the Performance Plus Package is still new to the company, Hopkins can expect to continue to feel more impact into the future.

“When we first got into the Performance Plus, we really didn’t know if this would make an impact on our company,” said Hopkins. “I can say now that our good operators are better, and our new operators are incredible as well. Everyone’s skills have improved significantly, and our business is thriving because of it.”