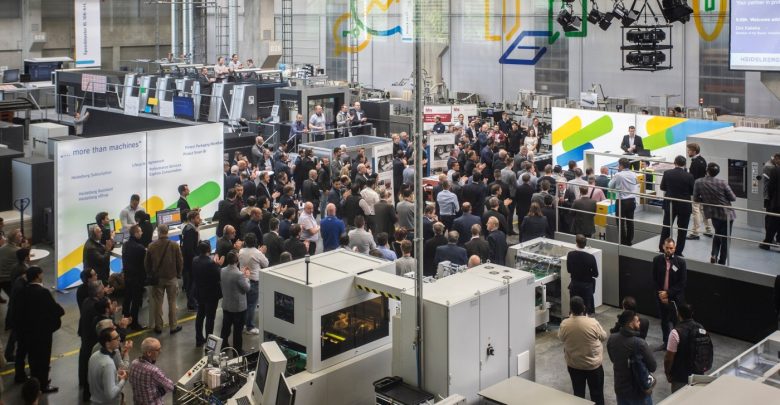

Heidelberg’s Packaging Days Sees Strong Interest in Packaging Solutions

In the middle of May, Heidelberger Druckmaschinen AG (Heidelberg) hosted its Packaging Days at the Wiesloch-Walldorf site with the theme “Together on Track to Success”. Over 350 participants from all over the world visited the Print Media Center Packaging on two days, where they demonstrated strong interested in Heidelberg’s integrated solutions and got comprehensive answers to the growing needs in the industry. Run lengths are declining, the number of individual jobs is increasing, raw materials are going up in price, and margins continue to be under pressure.

Heidelberg offers its customers a wide product portfolio for this, with standardized processes and largely automated workflows. “We are continuously enhancing the Smart Print Shop, and offer our customers assistance with the digital transformation,” explained Stephan Plenz, Member of the Management Board responsible for Digital Technology, during his welcome address. “On this journey, we want to give our customers lots of different ideas of how they can make their business model even more profitable.”

For example, the “Smart Packaging Production” agenda item showed how productivity and profitability can be significantly increased in an integrated overall solution. Networked with the Prinect Production Manager, the Speedmaster XL 106 six-color press with coating unit and logistics, the new Powermatrix 106 CSB die cutter, and the Diana X 115 folder gluer ran at full speed. The Powermatrix 106 CSB is the new high-performance die cutter from MK Masterwork.

It produces 8,000 sheets per hour and has many features expected by packaging printers, such as an elevated pile handling system and the optical MasterSet sheet register system as standard equipment. Its performance capability in a 24/7 environment will make the new Powermatrix 106 CSB an economical option for industrial packaging printers looking for an efficient die cutter.

The topic of multicolor, and therefore printing spot colors with three colors in addition to the basic colors in one pass, was demonstrated both on the Speedmaster XL 75 Anicolor and on the large-format Speedmaster XL 162. The fact that no color changes are required between the individual jobs greatly reduces washing and makeready times, which means much higher productivity.

The Primefire 106 industrial inkjet digital printing press demonstrated the personalization possibilities in “Packaging as you Like”. This allowed customers to discover how the latest digital processes can be seamlessly integrated with traditional offset methods – with the same substrates and the familiar finishing processes on existing postpress systems.

“One Pass, Infinite Possibilities” was popular with those interested in greater profitability through differentiation. The Speedmaster XL 106 eight-color press with double coating unit and the FoilStar cold foil module produced the most fascinating finishing effects, guaranteed to attract attention on any market shelf. This is how brand owners realize their eye-catching effects at the point of sale.

Following the market launch at a customer event in the MK Masterwork factory in Nove Mesto, Slovakia, the new Diana Go folder gluer (see press release dated from March 19, 2019) was installed in hall 57 in Wiesloch-Walldorf. Together with the Speedmaster CX 102 6+L and the Easymatrix 106 CS die cutter, the Diana Go represented the final process step in an integrated and cost-effective packaging line. The Diana Go, which incorporates many functions from the tried-and-tested Diana family, offers commercial and packaging printers a powerful folder gluer with a very compact footprint at an attractive price.

The new subscription digital business model was also explained in detail. The customer no longer purchases a press, but instead pays for an agreed monthly print volume. The service package for the customer consists of the machine, consumables, service, and workflow. This means planning certainty when it comes to costs, which frees up the printer to concentrate fully on their own customers and how they operate in the market. Heidelberg and the subscription customer have the same interests here, namely increasing productivity through a smooth, streamlined production process at a competitive level for greater profitability for the printer.