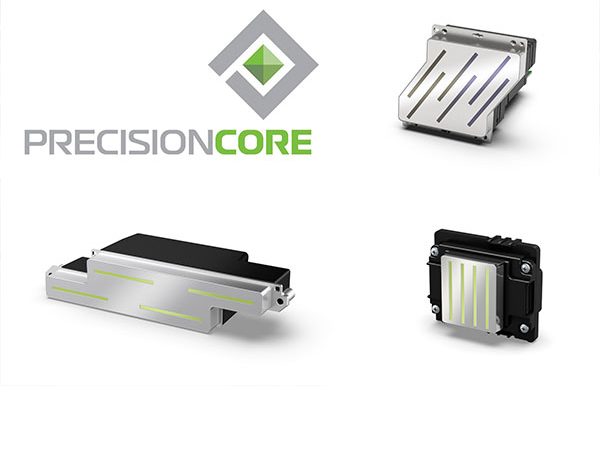

Epson Expands its Lineup of PrecisionCore Printheads

Seiko Epson Corporation has expanded its lineup of PrecisionCore printheads in response to an accelerated shift in the commercial and industrial sectors to digital printing, which produces less waste and offers a reduced environmental impact.1

Epson has developed three new printheads, including the D3000-A1R, the series’ first product to support ink circulation at the nozzle level. The new printheads will be released in the second half of the 2021 fiscal year (ending March 2022). The lineup of inkjet heads now comprises five series, thus further expanding potential applications in digital printing.

Product features

D3000-A1R

Ink is circulated at the nozzle level to prevent potential issues caused by the evaporation of moisture near the nozzles. Circulation also facilitates stable printing and increases the degree of freedom in the engineering of devices and ink. (Unlike printheads in the existing PrecisionCore S series, these printheads do not require regular ink ejection and head cleaning.)

With 1200-dpi resolution and high-frequency driving, these printheads enable digital printers to deliver image quality and print speeds comparable to those of existing analog printers.

There is no need to adjust the position of heads in multi-head arrays. This significantly reduces the amount of time it takes to assemble and replace the heads.

S3200-A3

The S3200-A3 uses the same 24 kHz frequency as the existing S3200-A1 yet produces droplets that are 1.4 times larger. It can deliver high print quality at high speeds even when the distance between the head and media is large, such as when printing on textiles and cardboard.

With an easily scalable S-shaped design and a robust structure, the S3200-A3 supports a wide range of needs and applications.

I3200(8)-A1HD

With up to 1200 nozzles per inch (when using two colors), the I3200(8)-A1HD has a higher nozzle resolution than the existing I3200(4)-A1, enabling it to deliver high-definition images in a compact size without sacrificing the characteristic usability of the series.

This head is suitable for both high-speed, single-pass printing as well as multi-pass printing.

The three new products will help accelerate the transition to low-waste, low environmental impact digital printing of things such as textiles, packages, and decorations. They will also facilitate distributed printing, allowing items to be produced locally, and on-demand printing, meaning that printers only produce what they need, when they need it.

The demand for digital printing with water-based ink has risen in recent years due to a desire to mitigate the environmental impact of printing. Epson will continue to develop original technology to contribute to the expansion of low environmental impact digital printing and further accelerate inkjet innovation.

1. Since digital printing is a shorter process than analog printing and does not require plates, it uses less electricity and water. It also produces very little waste ink. Digital printing is ideal for short-run print jobs and minimizes inventory loss at every step from production to sales.

2. Printing performance and head durability will differ depending on the type of ink used.