As broad as the spectrum of interests targeted at Fespa 2018, as diverse is the product palette Zünd is exhibiting at this year’s show in Berlin. Whether digitally printed vinyl or corrugated cardboard for POP, textiles for soft signage applications, the fashion industry, or for interior design, Zünd offers the perfect, high-performance cutting solutions to meet the diverse needs of print service providers anywhere.

From the “Digital Corrugated Experience” and “Print Make Wear”, to “Printeriors”, soft signage and a full gamut of printed POP, the focus of Fespa 2018 is extremely broad. As the premiere show for wide-format printing, it sets the perfect stage for Zünd (Booth B50, Hall 1.2) to show off the countless applications of its digital cutting systems and workflow solutions.

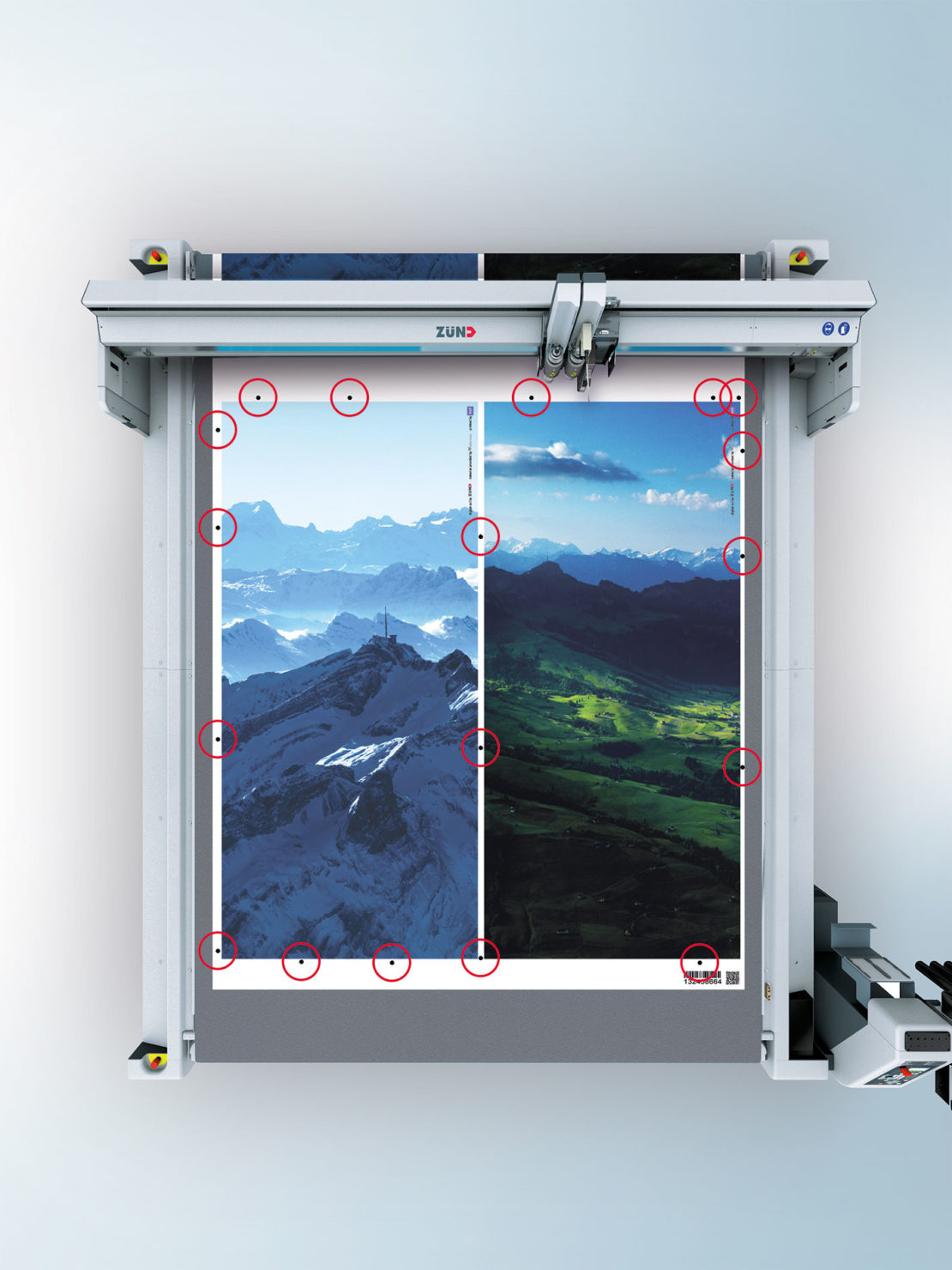

With the latest version of Zünd Cut Center ZCC software, Zünd is pushing the productivity envelope further than ever. The new Over Cutter Camera OCC, for example, provides fully automated registration that adjusts for position, stretch, or distortion in mere seconds. With a single shot, the OCC captures all register marks visible on the substrates in the cutting area.

ZCC then compensates for any stretch and enables the cutter to begin processing almost immediately. The browser-based Dashboard helps visualize performance data of the cutting system during production. Management and production supervisors can access Dashboard and all relevant real-time data round the clock, anytime, from anywhere.

In the sign and display industry, digitally printed textiles are becoming more and more popular. The demand for innovative, high-performance solutions is high, and Zünd is responding e.g. with the G3 3XL-3200. At Fespa this digital flatbed cutting system will be shown in combination with the LM 100W Cut & Seal Laser Module.

The system can handle rolls of fabric up to 3.2m / 126in wide. For automated processing of large-format rigid substrates such as carton or corrugated board, Zünd is exhibiting an integrated production line with a D3 cutter and the Board Handling System BHS. This system showcases automated loading of rigid materials combined with the exceptional productivity of D3 dual-beam technology.

The two independently operating beams can each carry up to three different tools, and depending on the specifics of the job, deliver up to twice the throughput. On another G3 cutter, market leader Zünd displays the latest in high-powered, fully automated routing technology.

The high-powered RM-L router spindle delivers up to 3.6 kW of power and unprecedented capabilities for processing hard, dense materials such as acrylics and wood. With the automatic router bit changer ARC, Zünd is offering users a solution for completely automating the routing workflow. Zünd high-performance routing combined with ARC automation offers unparalleled productivity for acrylics, Dibond, Forex, and MDF applications.