The dye sublimation inkjet textile printing market is set for a rapid acceleration in growth according to a new report from Smithers, the global authority on the print industry. New demand in garments, household furnishings, and technical textiles will generate sales of $11.8 billion in 2025.

The US-based research service provider’s new market report – The Future of Dye Sublimation to 2029 – projects a global output of 2 billion sq m of fabric and 73.6 million sq m of rigid media in 2025, marking the beginning of a significant upswing in demand for dye sub printed products. Global dye sub sales grew only marginally across 2019-2023. Demand for all end-use products fell significantly in 2020 because of the COVID-19 pandemic, with the display sector hit particularly hard.

The company’s analysis forecasts an increase in volume by 7.9% CAGR across the next five years, taking annual output to 2.9 billion sq m in 2029. Across the same period, the market will be valued at $15.2 billion, growing at 6.6% CAGR at constant prices.

The five main segments for dye sub printing are garments, household, technical textiles, displays, and rigids.

Garments (apparel) is by far the largest segment, 71.9% of contemporary volume. It will benefit from fashion industry trends to re-shore production from Asia to developed regions in North America and Europe. The use of heating to fix or transfer the dye can be accomplished either within the confines of the dye sub print unit, or via an external heat-transfer press or calender.

A parallel driver is the pressure to reduce the environmental impact of clothing production. Direct and transfer dye sub printing can decorate textiles without washing or steaming to fix the colour. This reduces the quantity of dye and other chemicals that might otherwise enter wastewater systems. Extended producer responsibility (EPR) schemes have been introduced in France, Italy, and the Netherlands, which will in future be extended to the UK and all EU member states.

Aqueous inkjet – accounting for over 98% of output – has emerged as the dominant ink technology for dye sub printing, with further reductions in the use of solvent and eco-solvent inks forecast through to 2029.

In soft signage, dye sub is benefiting from the emerging preference for silicone edge graphics (SEGs) in displays, light boxes, and general signage. SEGs are low cost and easy to install, while the use of dye sublimation printing provides highly saturated, vibrant images.

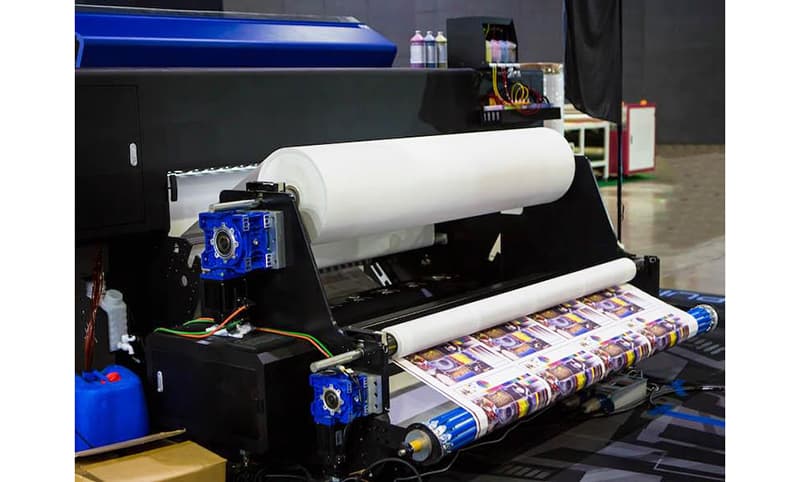

As dye sub demand evolves, OEMs will increase sales of new higher-speed machines including models with integrated heating systems to dry or fix inks, alongside a significant number of inkjet presses repurposed from other graphics work. Simultaneously, suppliers of consumables are working to decrease the base weight of dye sub papers, and produce textile coatings that optimise the use of high-glycol inks.

Dye sublimation is a process that is used to print images and information onto synthetic materials for a broad range of applications including apparel, household, sportswear, and signage, as well as some solid surface printing.

A common feature of all dye sublimation printing is the mechanism whereby a coloured dye changes from solid to vapour when heated. Heat coupled with pressure causes the dye to penetrate the interior of the substrate, creating a permanent colour bond. Once the heat is removed, the dye returns to a solid form and the process is complete. This is in contrast to textile and general printing, where ink is applied to the surface of the print medium, and the pigment in the ink colours the material.