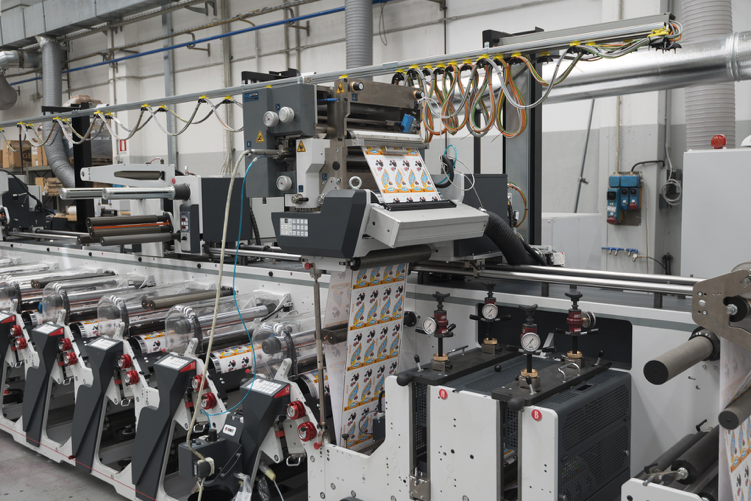

OMET is a company specialised in on-demand solutions suitable for customers’ needs, in order to raise their efficiency and their competitiveness. “An important example is a possibility of positioning the rotary screen-printing unit on a rail instead placing it on the printing station: this avoids losing one flexo station and helps saving space,” said the company in a statement.

The printers, who realise complex labels, need to use all the colours provided in the machine configuration, adding the screen-printing unit as additional printing group. Positioning it on a rail, you can avoid the loss of a station that can be used for the flexo-printing. Moreover, you can also take up a minimal amount of space in the production workshop, by optimising the space in terms of height rather than in length.

The silk-screen printing group is completely independent, both electronically and drive-wise; it has an integrated chilled impression cylinder and an independent UV lamp. It could be moved everywhere on the rail system inside the machinery’s track, even before or after other finishing units as the hot foil or the cold foil. Thanks to a special rail system the unit can easily be moved from one position to another just by sliding them and without removing them from the machine.

This is just an example of a creative solution developed in collaboration with the client in order to solve specific needs with the aim of being more competitive. Machinery designed with personalised configurations lead to strong advantages for the printers, in such a competitive market.