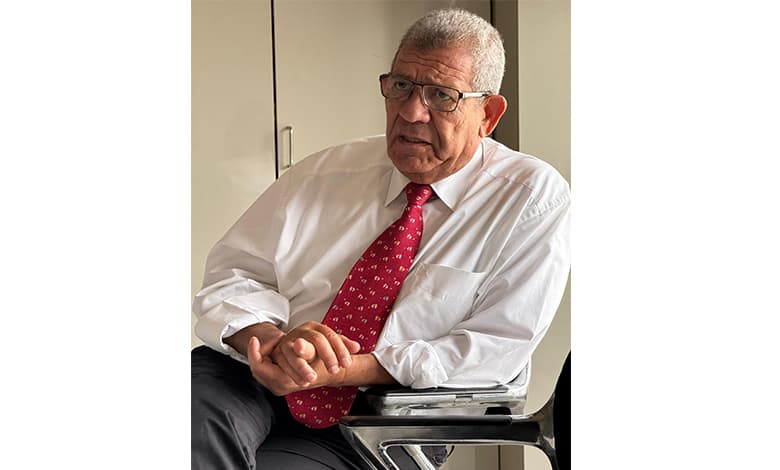

In conversation with Adel Allam, CEO, and Youssef Adel, Managing Director, Youssef Allam Group

When you started your business in 1948, what were the biggest challenges faced?

The challenges began a few years after we started in 1948, mainly due to political instability in Egypt, including revolutions and war. These were some of the major challenges back then.

Back then, there was dominance of foreign traders in paper. How did you overcome that?

My father had a vision to revolutionize the paper industry in Egypt. After establishing the paper trading company in 1948, he led the paper trade in Egypt. He became the “lone dreamer” in the market, which was dominated by foreign traders. By the 1950s, we were very active in the market. The Korean War created supply shortages, but we had good relations with European suppliers, especially in Austria, allowing us to fill the market gap. My father’s efforts earned him the title “King of Paper.” Despite the challenges, we continued to develop the paper market in Egypt.

By 1968, all activities were done through the government. My father then decided to establish a print shop. Trading was not easy, but he managed to import huge machines from East Germany, including a big perfector printing machine. Before we could run it, an army truck took the machine away. Despite various issues, we eventually established relations with the West and took the agency of HEIDELBERG in 1970. We started offset printing alongside letterpress. The army, which had used our initial machine for several years, later expressed a desire for a new machine, so we sent them a HEIDELBERG Rotaspeed.

Over time, we were successful in selling machines while developing our paper business. In 2013, we entered the cardboard market with Uniboard, one of the biggest companies in Africa and the Middle East. Uniboard produces high-quality duplex board, and we are a major partner in this successful venture, exporting to new areas.

I was at the HEIDELBERG booth during the press conference where they introduced their new inkjet machine. What do you think about their new venture with Canon?

When they collaborated with Kodak in 2000, the Nexpress digital printing machine was very good, designed by HEIDELBERG. However, the relationship ended, and Kodak took over Nexpress. They also had the DI dry offset press using plastic plates, which was very successful for us, especially in Libya. The DI machine had easy plate-making with no misalignments and good print quality, but the plates were a problem. Only one company provided the plates, and HEIDELBERG discontinued the machine.

How many business units does Youssef Allam Group have, and how do you manage them as a whole?

We have seven units: digital printing, flexo, offset, medical, archiving, paper, and cardboard. Each unit is independent with its own management team, but the overall concept is the same. Despite having different clients, there are many similarities among the units. Ultimately, it’s about trading, selling machinery, consumer bills for clients, and providing maintenance.

Can you tell me about the digital printing market in Egypt?

We started with digital inkjet printers long ago. Today, inkjet is everywhere at drupa, but we had the RISO full-color inkjet printer in 2000, being one of the first to have it in Egypt. Our expertise in digital printing dates back over 24 years, with substantial knowledge in the inkjet business. Now, we also have Ricoh machines.

Everywhere digital is showing double-digit growth, while offset is flat. Yet, people in the Middle East still prefer offset. Why?

The decline in newspaper and book printing has been replaced by packaging. HEIDELBERG machines lead the offset packaging business, including IML machines, which are top sellers globally. These trends are evident in the market, with many print shop customers transitioning from commercial magazine printing to packaging.

HEIDELBERG is moving towards full automation. Will this work in the Middle East or specifically in Egypt?

Some clients see the value in the options offered, but due to the devaluation of currency, machines are very expensive for print shops.

One of the biggest challenges facing the printing industry is a shortage of skilled labor. Is this also true in Egypt?

Yes, many clients are hesitant to invest in new technologies, fearing their labor force won’t cope. We try to convince them that new technologies reduce dependence on skilled labor. However, currency devaluation makes full-option machines very expensive. Due to all these circumstances; Youssef Allam Group took the initiative and completed preparing a training course to qualify technical education graduates to work in printing production companies in Egypt, which will be conducted at “Allam print Media Academy” in cooperation with the German Chamber of Commerce, and Education for Employment – Egypt (EFE). We are committed to empowering the youth and contributing to the growth of the printing industry in Egypt.