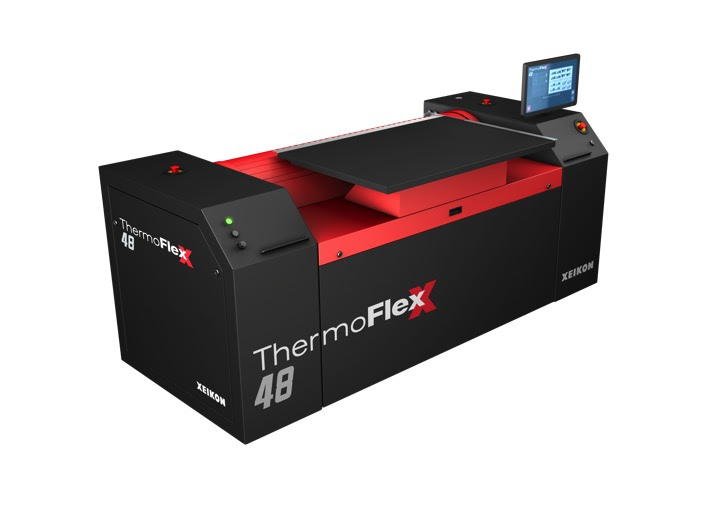

Xeikon Prepress, part of the Flint Group, will demonstrate platemaking solutions that optimise and drive productivity at Labelexpo Americas, Chicago, 25 to 27 September. Xeikon Prepress can be found in Hall A, Stand 728 at the show. Xeikon Prepress which designs and manufactures high quality, robust Computer to Plate equipment, digital platemaking systems under the ThermoFlexX brand name and CtCP as basysPrint, will show the ThermoFlexX 48-S.

It offers fully automatic plate loading and unloading with a productivity up to 6m2/hr and a choice of imaging resolutions up to 5080 dpi. With the latest imager and multiplate software release customers will benefit from an optimized output, automatically selecting the best quality at the highest productivity.

The ThermoFlexX User Interface automatically informs the operator for basic preventive maintenance actions, keeping the imager in perfect condition. Xeikon’s enhanced WoodPecker II solution provides surface screening at different resolutions, without sacrificing productivity. Depending on the substrate, there is a choice between single and multipixel surface screening patterns offering a smooth ink lay-down and increased solid ink density.

Christophe Lievens, Director of Sales & Marketing of ThermoFlexX, says: “We will be showing a range of solutions designed to deliver the highest quality results quickly and consistently. They will optimise productivity to ensure that production is as streamlined and as smooth as possible which supports workflow efficiency.”

Also on the stand Flint Group will host a speaker’s corner where industry experts will share their knowledge and a “Happiest of Happy Hours”.