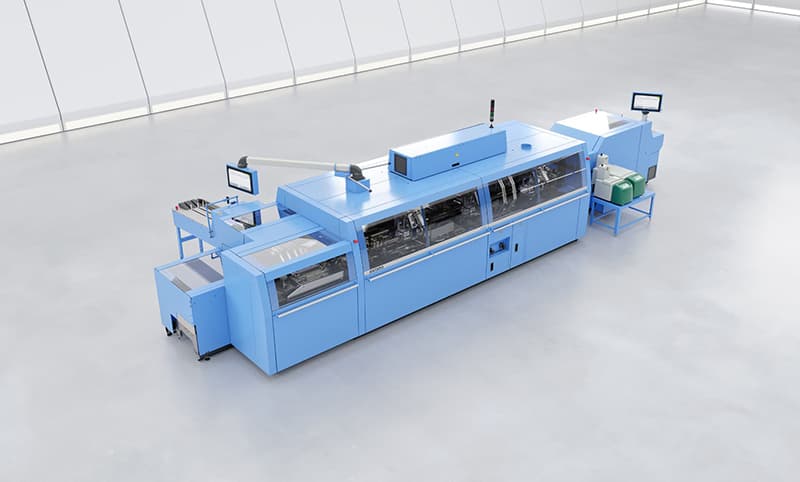

Muller Martini, a pioneer in print finishing solutions, is proud to unveil the Antaro perfect binder, available in two versions. This groundbreaking new binder platform redefines efficiency and versatility within a smaller footprint.

A Perfect Binder for Every Need

Muller Martini’s Antaro binder is designed to meet the evolving demands of the print industry for both on-demand and conventional, offset applications:

- Antaro Digital: For digital finishing applications, the Antaro Digital stands in a class of its own, producing print-on-demand books at an unparalleled rate of up to 2,000 cycles per hour – an industry-leading achievement, while requiring minimal staffing.

- Antaro: For offset print applications, the Antaro delivers at an impressive rate of up to 4,000 cycles per hour. Its robust performance makes it the perfect choice for short-run offset production in small spaces.

Unparalleled Flexibility and Investment Protection

The Antaro platform brings flexibility and investment protection to the forefront. Its modular, expandable design caters to both digital nearline/inline production and conventional production environments:

- Antaro Digital: This version takes single book production to a new level, offering automation with manual feed or inline connection to the SigmaLine Compact digital book production system. With six clamps, it achieves an impressive output of 2,000 books per hour. Plus, its compact design delivers the same output with fewer than half the operators required by current single-book production solutions.

- Antaro: When combined with a gatherer and equipped with 12 clamps, the Antaro shines in offset runs, delivering an output of 4,000 cycles per hour.

Efficiency through Automation

Both Antaro models feature a continuously running swing clamp system, ensuring the smooth horizontal transport of book blocks through the machine. The Antaro Digital’s unique clamp design enables the continuous production of brochures with varying block thicknesses of up to 20 mm, all at the highest performance level. These thickness variations are changed automatically, ensuring an unsurpassed productivity rate of up to 2,000 copies per hour for digitally printed products.

Exceptional Quality Guaranteed

The Antaro is equipped with two spine preparation stations, guaranteeing the highest quality book binding. The system utilizes EVA and PUR adhesives, backed by a glue monitoring system in the PUR nozzle for precise glue application. Replacing the gluing units is straightforward, enhancing maintenance efficiency.

The Antaro Digital features a newly designed drum coverfeeder coupled with a cover buffer wheel for reliable separation of covers and uninterrupted production through continuous feeding. Its barcode reader ensures a exact 100% match between book blocks and covers. The system’s buffer wheel creates sufficient distance for barcode reading, enabling automatic responses in case of mismatches without interrupting the binding process. Together with the standard cover reject feature positioned in front of the scoring device, this system achieves a new level of productivity through waste reduction.

Unrivaled Versatility

The Antaro platform flawlessly combines trusted technology from Muller Martini with innovative features. It accommodates all conventional types of book blocks, including signature stacks, pre-glued or thread-sewn book blocks, as well as single-sheet stacks. Even without an inline connection, manual feeding is ergonomic and efficient. The platform surpasses other systems available today with its exceptional end-product delivery capabilities, spanning softcover brochures, hardcover book blocks, flex brochures, glued book blocks, and layflat brochures. Set to redefine the print finishing landscape, it offers unmatched efficiency, quality, and adaptability.