There’s something about Denmark and the Danes – a kind of intellectual bonding that manifests itself in commercial cooperation and mutual assistance. Nick Coombes visited Grafisk Maskinfabrik in Birkerød and spoke with company CEO Uffe Nielsen to find out more.

Grafisk Maskinfabrik A/S, or GM as it is more usually known, began life in 1980 manufacturing electronic controls for a range of different engineering companies, and as such developed a highly skilled and knowledgeable workforce that was able to turn its hand to more than just electronics. By 1983 the decision was made to diversify the business and GM engaged in manufacturing in its own right, and began to develop a range of slitters, die-cutters, and sheeters for the narrow web sector. In the mid 90s, fellow Danish company Nilpeter requested the expertise of GM to develop finishing lines for digital print, and this became the start of a journey towards fully automated tool free laser-based finishing systems.

According to GM’s CEO Uffe Nielsen: “There is something of a Danish hub in manufacturing, which from a country of only 5 million people makes us rather special – in fact it’s a policy that is actively encouraged by the Danish authorities who are keen to establish a degree of independence and a high-quality pedigree in design and manufacture. And it’s not just in industrial products – look at Danish furniture, glassware, and other consumer items – they have a style of their own, and a reputation for quality.”

Over the next 15 years, GM prospered but also noticed the growth of digital technology in the label market – digital technology that included printing but little else. “Having cut our teeth in manufacturing with simple but cost-effective converting equipment, we spotted a niche for something more ambitious in the way of a complete finishing line. Flexo label presses offered this single pass to finished product, digital presses didn’t, and we took the opportunity to fill that gap,” explained Nielsen.

To make such a leap required massive additional funding, and with the aid of Dansk Ejerkapital, GM turned itself almost overnight from a small artisan workshop into a modern production outfit that has seen staff numbers rise from 60 to 140, and sales increase by almost 30%. But moving into finishing required the assimilation of new techniques and technology, including surface treatment of the digitally printed web prior to it being further processed.

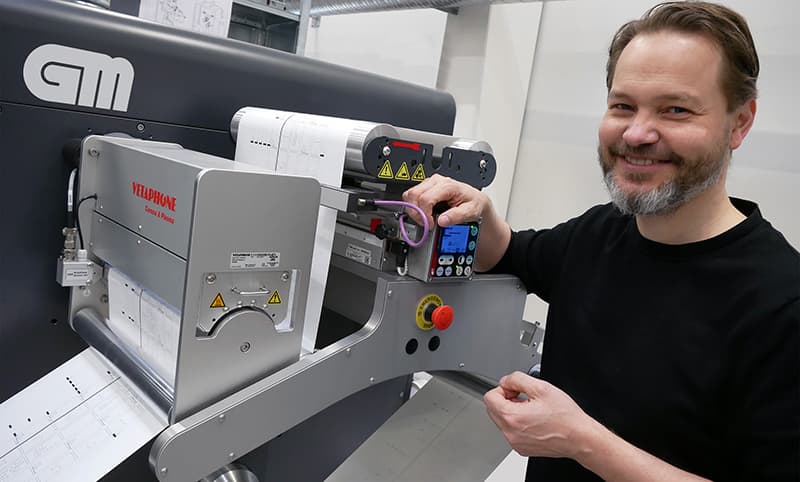

“We knew of corona treatment but little more than that until we investigated the market and found the pioneers and technology leaders were not only Danish, but only two hours away from our HQ. To say the rest is history exaggerates the point, but when you have Vetaphone’s vast wealth of knowhow and experience to draw on, in a common language and the same time-zone, and with an R&D philosophy that mirrors our own, why would we look elsewhere?” he added.

The cooperative partnership effectively began in 1998 and has thrived ever since. With run lengths seemingly in permanent decline as brand owners shy away from large inventories, what label converters need today is a flexible production capability that offers maximum on-shelf impact. “We buy with our eyes,” said Nielsen, “so labels need to attract attention as well as supply vital information, much of it governed by international legislation. The label is probably the hardest working element in printed packaging, so ensuring that it is always of top-quality is essential – re-runs are wasteful and costly, so all production elements need to perform reliably – and guaranteed correct surface treatment on some of today’s tricky substrates is the difference between profit and loss.”

With a global user base to support, GM is also grateful for the international back-up offered by Vetaphone and its sales and service network. Today’s competitive marketplace makes no allowances for sustained periods of downtime in production, and this applies to printing and converting as much as any other process. Printed packaging is the largest sector of the print market and is predicted to continue its rapid growth as more of the world moves into buying branded goods, so getting it right first time, every time, is critical.

But the Covid-19 pandemic has seen a major change in business habits and processes. Long periods of lockdown prevented sales and support staff from travelling to see customers in person, and GM, along with Vetaphone, has invested heavily in showroom and demonstration facilities that allow online presentations of technology that no exhibition could manage. Speaking for Vetaphone, CSO Jan Eisby commented: “The likelihood of most of our potential customers ever visiting us in Denmark is slim – so, with the lack of trade fairs to exhibit our technology we set about creating a means of taking Vetaphone technology out to the world.”

This chimes well with Uffe Nielsen, whose fully equipped demo facility at Birkerød has added scope to the company’s sales and marketing approach. “With our extensive range of equipment these days, the ability to hold live online demos is a great sales tool. Whether potential customers are interested in a general overview of our technology of something more specific, we have the facility to accommodate their needs,” he said.

Knowing the two companies and seeing their facilities and capabilities makes this whole ‘Danish hub’ concept come to life. Both exude an air of assured competence based on an in-depth understanding of their respective technology and attention to detail both internally through R&D and manufacturing, but also externally by listening carefully to each customer’s specific requirements. As Eisby concluded: “We are very proud of our heritage as a company and as a nation, and if this translates into providing a quality product and quality service to our customers in partnership with other manufacturers, that sounds like a winning formula to me!”

Today, both companies are acknowledged as market leaders in their respective sectors of operation, with the ongoing commitment to R&D and quality control that are requisites for Industry 4.0. As the demand for more sophisticated packaging continues to grow, close cooperative partnerships of this type will be essential to satisfy the demands of brand owners and legislators alike.