Meteor Inkjet Ltd, leading supplier of electronics, software, tools and services for industrial inkjet, is developing printhead drive electronics and software for the new T3200, T1600 and D3000 printheads recently announced by Epson.

These solutions join Meteor’s existing products to drive Epson S3200, S800, I3200 and I1600 printheads, ensuring that Meteor continues to provide the most complete range of Epson industrial printhead driving solutions on the market.

Epson printheads embody technology that enables outstanding image quality, productivity, durability and printhead scalability.

The new T3200 and T1600 printheads incorporate a different piezo actuator from Epson’s I3200 printhead, which allows ejection of larger drops at higher frequencies. More significantly, the T3200 and T1600 are Epson’s first printheads to include built-in heaters, which is especially important for signage and product packaging applications.

The new D3000 offers 1200dpi and is Epson’s first printhead to support ink circulation at the nozzle level. This circulation facilitates stable printing and increases flexibility in the engineering of systems and ink. The D3000 also incorporates new positioning architecture that eliminates the need for elaborate printhead adjustment, thus significantly reducing assembly time for multi-head arrays.

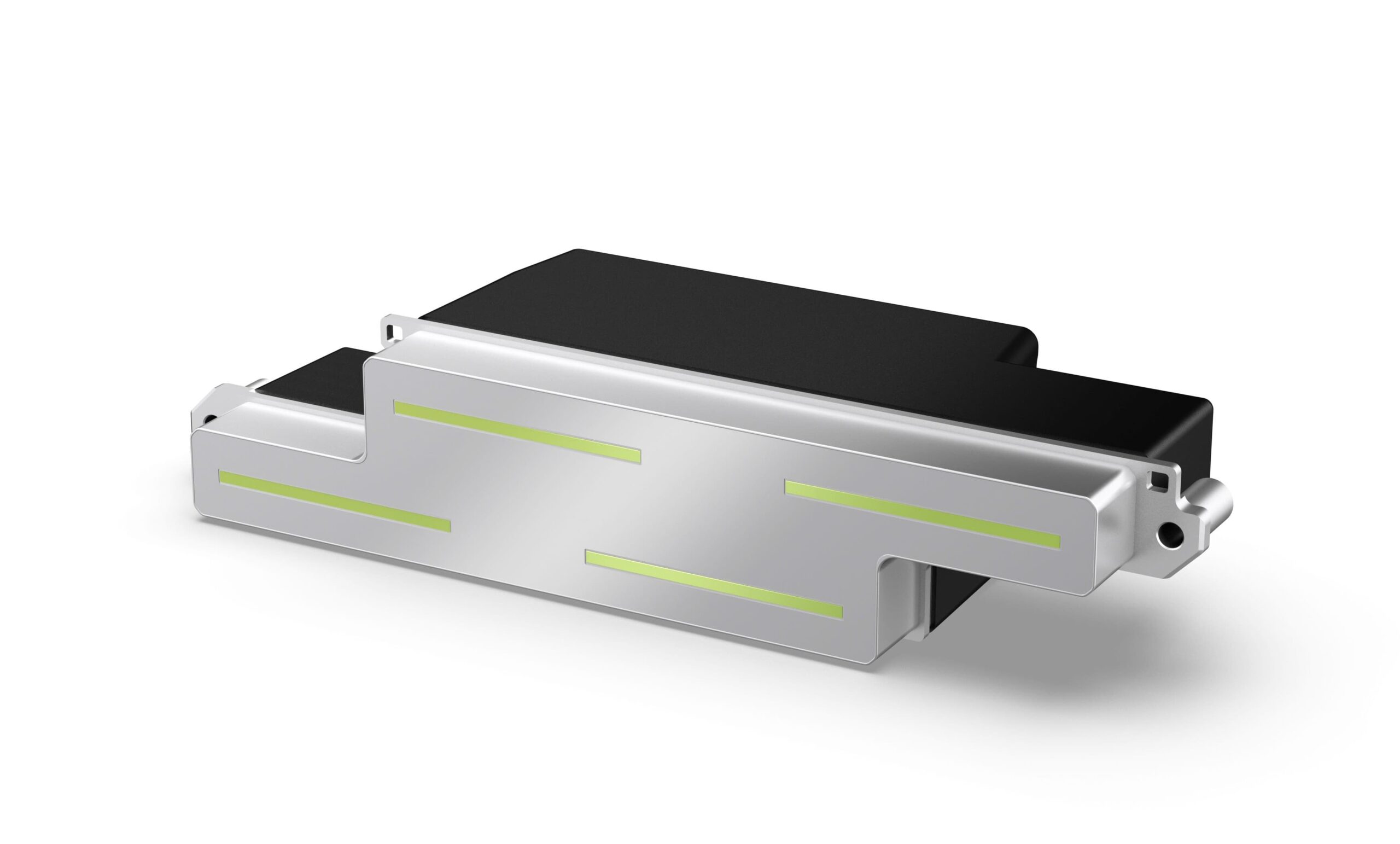

Meteor’s driving solutions for these printheads are designed with space and cost efficiency at heart. Together with comprehensive software, Meteor electronics are readily scalable to systems of any size and offer straightforward integration of different printhead types within a single printer. Meteor’s DropWatchers and printhead waveform development services will be available for the new printheads, providing essential tools to accelerate time to market.

Jonathan Wilson, Meteor’s sales director, comments, “Our continued cooperation with Epson will allow our mutual customers to take advantage of everything these new printheads have to offer. Meteor’s electronics and software provide the fastest and easiest way for OEMs to unlock the potential of these printheads, allowing print system builders to reduce the effort and risk associated with design and delivery of superior industrial inkjet printers.

Availability of Meteor solutions for these new printheads will coincide with availability of the printheads.”