The digital revolution has irrevocably altered the landscape of manufacturing, placing unprecedented demands on industries like print, packaging, and consumer goods. Aging labor forces, razor-thin margins, and volatile supply chains have left businesses scrambling to keep pace. Yet, amid these challenges lies a transformative opportunity: intelligent workflow infrastructures. These systems—rooted in automation, data integration, and modular design—are no longer optional but essential for survival in an era where speed, precision, and adaptability define market leaders.

This article dives into the blueprint for building workflows that not only streamline today’s operations but also pivot seamlessly for tomorrow’s disruptions. From the shop floor to the cloud, we explore how to:

- Eliminate bottlenecks with rules-based automation, reducing manual touchpoints by up to 80%.

- Centralize control using MIS/ERP systems as the “single source of truth,” bridging siloed departments and external partners.

- Future-proof investments through modular, cloud-native tools that adapt to evolving technologies like AI and IoT.

- Conquer data chaos by harmonizing disparate formats (XML, JDF, JSON) into actionable insights.

We’ll dissect real-world strategies for overcoming legacy hurdles, from retrofitting analog equipment to deploying AI-driven schema mapping. Whether you’re a commercial printer battling custom job complexity or a packaging converter eyeing on-demand production, this guide offers a roadmap to resilience.

What’s Inside?

– Automation in Action: How platforms like Enfocus Switch and Ultimate Bindery are slashing prepress delays and automating bindery setups.

– Data as the New Currency: Why PDF/X-4 standardization and AI-powered preflight tools are non-negotiable for error-free workflows.

– The Cloud Advantage: Cutting costs with pay-as-you-go models while scaling operations globally.

– Hybrid Customer Models: Blending B2B EDI integrations with B2C storefronts to capture diverse revenue streams.

The clock is ticking. Companies clinging to manual processes risk obsolescence, while early adopters are already reaping 30% efficiency gains. Ready to transform your workflow from a cost center to a competitive edge? Let’s begin.

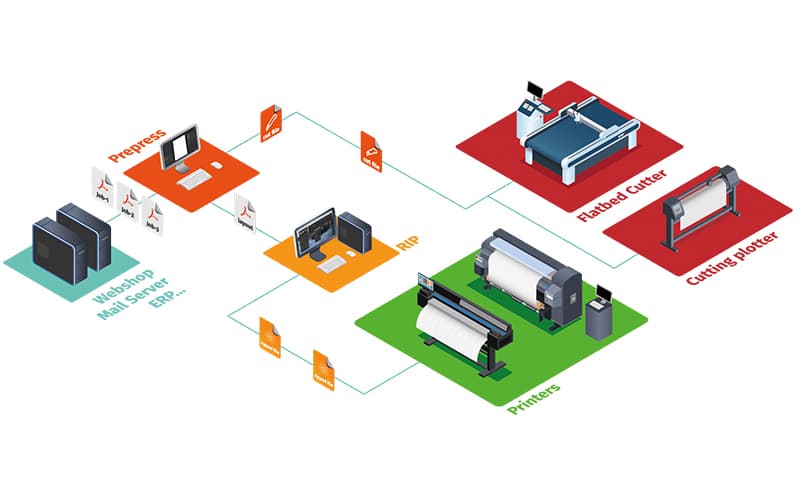

- Layered Infrastructure: Building Blocks of Automation

Intelligent workflows rely on interconnected layers that balance modularity and integration.

– Production Layer:

– Automation Tools: Platforms like Enfocus Switch and rules-based pipelines automate job onboarding, preflight checks (using Pitstop Server or callas pdfToolbox), and imposition.

– Process Steps: Streamline input (via Web2Print portals or XML/EDI feeds), prepress (automated PDF/X-4 standardization), output (digital/offset device routing), and delivery (tracking integration).

– Flexibility: Digital presses enable “late binding,” allowing last-minute job rerouting based on capacity or deadlines.

– Process Management Layer:

– Rules-Based Control: Systems monitor job status, load balance across devices, and trigger alerts for exceptions (e.g., missing files).

– Vertical/Horizontal Integration: Sync data between prepress, press, and finishing (e.g., JDF-driven bindery setups with Ultimate Bindery).

– Business & Information Management Layer:

– MIS/ERP Centralization: Acts as the “single source of truth” for job tickets, inventory, and customer data. Modules include estimating, CRM, and real-time dashboards.

– Cloud Integration: Solutions like PrintLogic or EFI Monarch enable remote access and scalability.

– External Interface Layer:

– APIs & Web Portals: Direct ERP-to-ERP integrations with clients automate order entry and billing. B2B portals (e.g., custom storefronts) let clients track jobs in real time.

2. MIS/ERP: The Heart of Intelligent Workflows

A robust MIS/ERP system is non-negotiable for scalability.

– Core Features:

– Job Ticketing: Captures specs (substrate, color profiles, finishing) via XML/JSON feeds.

– Shop Floor Tracking: Monitors press uptime, material usage, and labor costs.

– Cloud vs. On-Premise: Cloud solutions (e.g., Avanti Slingshot) reduce IT overhead, while on-premise systems offer deeper customization.

– Implementation Challenges:

– Legacy Systems: Older equipment may lack JDF compatibility, requiring middleware like Adeptia for connectivity.

– Data Silos: Overlapping tools (e.g., multiple W2P solutions) create fragmentation. Normalize data upstream using MIS-driven workflows.

3. Cloud & Modular Solutions: Flexibility Meets Efficiency

– Cloud Advantages:

– Cost Savings: Pay-as-you-go models (e.g., Salesforce for CRM) eliminate upfront hardware costs.

– Scalability: Easily add modules (e.g., AI-driven estimating tools) without disrupting existing workflows.

– Modular Best Practices:

– Mix & Match: Pair Enfocus Switch for automation with Ultimate Impostrip for imposition.

– Avoid Silos: Use middleware to bridge disjointed systems (e.g., connect digital presses to legacy bindery equipment).

4. Data Standardization: The Rosetta Stone of Automation

– Key Formats:

– XML/JDF: Industry standards for print job specs, enabling press-to-bindery communication.

– JSON/API: Facilitates cloud integrations (e.g., pulling client data from Shopify into an MIS).

– PDF/X-4: Ensures print-ready files with embedded color profiles and fonts, reducing manual prepress fixes.

– AI-Driven Mapping:

Tools like Informatica use machine learning to auto-map client data fields (e.g., “Due Date” in a client’s CSV to “Delivery Date” in your MIS).

5. Challenges & Tactical Solutions

– Legacy Equipment:

Retrofit older devices with IoT sensors or use hybrid workflows (e.g., manual entry for analog presses paired with automated digital lines).

– Exception Handling:

– Checkpoints: Flag missing files via automated preflight; route exceptions to CSRs or prepress.

– Smart FTP: Use tools like Liquid Files to auto-capture missing metadata from client uploads.

– Labor Shortages:

Automate repetitive tasks (e.g., Ultimate Bindery for setup-free finishing) to free staff for high-value roles.

6. Endgame: Agility Through B2B/B2C Hybrid Models

– B2B Workflows:

– Custom Portals: Offer clients branded hubs for ordering, proofing, and tracking.

– EDI Integration: Automate high-volume orders (e.g., CPG packaging) with XML-based purchase orders.

– B2C Workflows:

– Constrained Design: Use tools like DesignNBuy for templated products (e.g., business cards).

– AI-Driven Customization: Platforms like Cimpress leverage AI to auto-correct customer-uploaded files.

– Hybrid Strategy:

Blend automated B2C storefronts with CSR-managed B2B exceptions (e.g., complex packaging jobs requiring substrate approvals).

7. Roadmap to Implementation

Start Small: Automate onboarding first (e.g., deploy a W2P portal for 20% of orders).

Standardize Processes: Enforce PDF/X-4 and preflight rules to reduce errors.

Invest in Training: Upskill staff on MIS analytics and exception management.

Phase In Cloud Tools: Migrate file storage and MIS to the cloud incrementally.

Monitor & Iterate: Use dashboards to track automation ROI (e.g., reduced touchpoints per job).

Final Takeaway:

The future belongs to businesses that treat workflows as living systems—adaptable, data-driven, and customer-centric. By prioritizing automation, breaking down data silos, and embracing modularity, print and packaging firms can turn today’s disruptions into tomorrow’s opportunities.