There is no doubt Bobst has strong roots in packaging industry and its strategy towards future will have an impact on the printing and packaging industry as well. Bobst boasts new vision for the future and according to CEO Jean- Pascal Bobst Swiss manufacturer’s open architecture cloud platform, Bobst Connect, was at the heart of this vision, and described workflow as the biggest challenge for the sector. Bobst has also outlined a new vision for the future whereby all parts of the packaging supply chain, from brand owners to converters and retailers, will be seamlessly connected. In order to find out more about this new vision and the path Bobst has chosen for these uncertain times we talked with François Martin Bobst Group’s Marketing and Communications Manager and Moez Jebali, Middle East Business Manager for Folding Carton.

François Martin Bobst Group’s Marketing and Communications Manager

Q: Recently Bobst announced that it would no longer be attending Drupa, or most other industry trade shows, instead the company invested heavily in its ‘Competence Centers’, which would be evolved “to the next level”, do you believe the era of major trade show is over?

Martin: We believe that change is inherent to any industry – industry tradeshows had their importance and some are still very relevant. However, and by industry, this is important continuously assess the role of tradeshows. Over the last 10 years, many manufacturers, including BOBST, have invested in “competence centers” and these investments are additional opportunities to meet the customers. So, we see tradeshows to become almost an association and as such they need to rethink how they share information without having to rely only on face to face events with tons of equipment shipped over the planet. The world is changing and tradeshows need to evolve as well. So major tradeshows need to build a plan for their future and this by industry and by regions.

Q: What role Competence Center plays in overall Bobst vision for the future?

Martin: Customers, all see a visit to the competence center as a major element in their investment plan. They all want a private and personal demonstration looking at specific elements from a given solution. The Competence Center have indeed have been built to answer this need. In the future, we believe that such request will grow even more. Customers are all unique and they want to differentiate versus their competitors. They want to engage with BOBST in a close relation and we can offer it in the Competence Center. We are also adding intelligence to machines and the demonstration of the new machines requires more detailed presentation of elements which can’t be shown on a traditional tradeshow.

Q: How your customers in the Middle East can benefit from this center, while travel restrictions are still in place and it seems it will be with us for some time?

Martin: We understand the current travel restriction and we hope they will soon be released. In the meantime, we are offering our clients the ability to run virtual demonstration in our competence center. We in fact do more than what we though and from countries very far away giving them the opportunity to safe time. New technologies are no so new anymore and virtual demonstration works very well. Simply try one and you will change your mind about being remote.

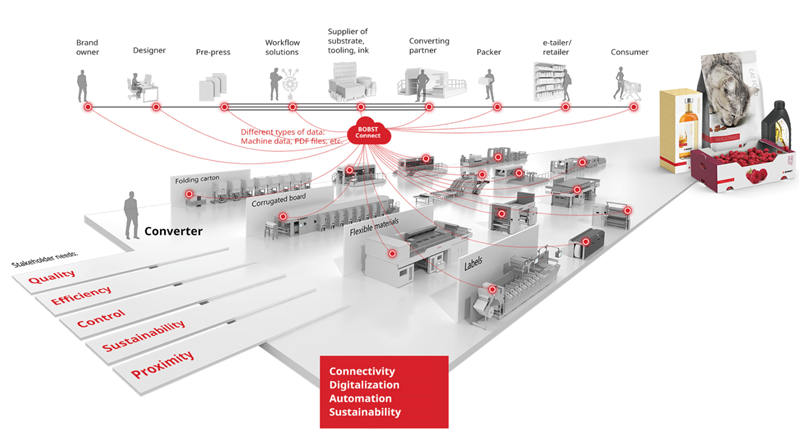

Q: Based on Bobst new vision for the future all parts of the packaging supply chain, from brand owners to converters and retailers, will be seamlessly connected, what does this mean for the customers and the products you are launching?

Martin: For the new products we are launching we ensure that they all comply to the strategy we defined. We check that they are connected, digitalized, automated and more sustainable. This we do across all the products we are launching. This is by adding intelligence to existing machines that we will enable packaging production to be more effective. We want to build our new machines to be able to answer the fundamental needs of the brand owners who require agility and sustainability. The way packaging production was done is OK but still very slow and complicated – we believe it will change.

Q: You recently announced a raft of new enhancements for your equipmentincluding TooLink Connected Tooling, which allows the die-cutting machine to automatically detect the type of tool being used, are these innovations all part of the Bobst vision for future or it is just a simple tweak?

Martin: TooLink is in fact a very accurate outcome of the new vision. We could have done a Dye-cutter handling more sheets per minute but would converters be more productive?I am not sure. The reduction of job sizes put more pressure on the tooling and the time required at each job change. By working on the digitalization of the tools loading we came with the idea of TooLink which truly enable more sheets on the floor.

Q: Bobst is also making a major push to standardize extended color gamut (ECG) printing in the packaging industry, can you elaborate about this?

Martin: The ECG technology helps printers to avoid the costly and complicated ink mixing. It also reducescosts (not special inks) and the environmental impact (less ink consumption and no washing). Brand owners understand the benefits of the ECG technology as it will enable color consistency across platforms and continents independently of the press operator. BOBST was already engaged in the ECG technology and we now took to next levels across all the platforms (Narrow Web Flexo, CI Flexo, LF Flexo and soon Gravure). We gave it a name across BOBST: oneECG. This technology has been designed with key partners to ensure its deployment deliver the best performance again and again across continents.

Q: For Bobst automation and workflow are the major ingredients for the future of print do you think your customers in the region are ready to embrace it? How do you plan to help them achieve that?

Martin: Workflow are nowadays the most critical element to enhance packaging press. You clearly can say that it takes more than a press or a finishing line to be successful. Like within any industry, the outcome of a given process is as solid as the agility within each individual steps. The current packaging production is built on legacy processes where connectivity and digitalization where not part of the equation. Progress where primary made by increasing the automation and the engine speed.

Q: Your Mouvent digital printing subsidiary, which makes inkjet presses for label and textile printing, is facing tough competition from other vendors, do you think it was a right decision for Bobst to enter this particular market?

Martin: The digital market is indeed crowded but we all know that the digitalization of the entire process is required – printing and converting. We have looked at this segment carefully and in labels we have a very compelling value proposition. Yes, this is new for BOBST but we can’t move away from the demand from our customers. We are convinced this is the right decision to be active in digital as the future of packaging will be driven by 3 main forces: connectivity, digitalization and automation.

Moez Jebali- Middle East Business Manager for Folding Carton

Q: How did Covid 19 affected Bobst activities in the region and do you believe we are on the road to recovery?

Jebali: Bobst activities in the region were affected by the restriction of movement and travel of our engineers. Nevertheless, we could delegate our engineers to service the machines in the country where they are based, and when this was not possible we assisted the customers remotely.

Q: There was a silver lining for companies involved in packaging? There is a sharp increase in demand for packaging, did this trend had also positive effect on your business as well?

Jebali: There was an increase in the demand of packaging for certain fields but also a decrease for other areas; Client are asking for more automated solutions and multifunctional, we have seen an increase on projects for water based printing solutions and a big concern for sustainability.

In result the packaging production remained stable or slightly decreased. This situation and the related uncertainty for markets and businesses has led some customers to a temporary freeze the investments and delay some projects.

About BOBST

Bobst is a leading supplier of substrate processing, printing and converting equipment and services for the label, flexible packaging, folding carton and corrugated industries.

Founded in 1890 by Joseph Bobst in Lausanne, Switzerland, BOBST has a presence in more than 50 countries, runs 15 production facilities in 8 countries and employs more than 5 500 people around the world. The firm recorded a consolidated turnover of CHF 1 636 million for the year ended December 31, 2019.

Please check it out BOBST industry vision by François Martin is explaining our BOBST vision on the industry;