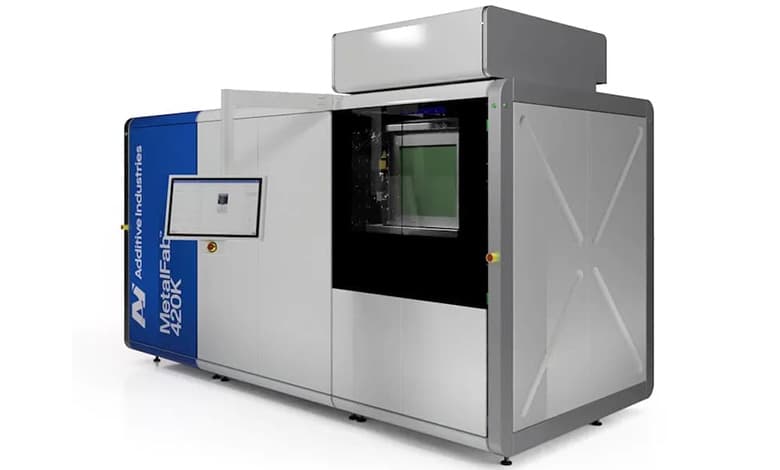

Additive Industries, the Netherlands-based manufacturer of metal 3D printers, has introduced the MetalFab 420K, its latest flagship model. This new system is a highly automated and modular metal 3D printer that integrates a powerful configuration of four 1-kilowatt lasers, specifically engineered to boost productivity and meet the stringent quality demands of high-stakes industries such as space, aerospace, automotive, and high-tech sectors.

The MetalFab 420K distinguishes itself with several advanced technological features, most notably its ability to deploy a combined 4kW of laser power across a substantial 420 x 420 x 400mm build volume. The Eindhoven-headquartered company states that this robust design allows each of the four full-field lasers to access the entire build plate, enabling scan speeds and power levels without compromising essential material quality.

The system incorporates several technical advancements designed to push the very boundaries of metal 3D printing. It features four independent 1kW lasers operating across the entire build platform. A unique process parameter is the variable beam diameter, which allows calibration from 100 to 500 microns, providing valuable flexibility for diverse material and process developments.

Optimised quality control is maintained through advanced gas flow dynamics, sophisticated oxygen and humidity controls, and automated calibration routines that ensure consistency and quality across the entire powder bed. Furthermore, an open architecture provides users with full freedom to develop proprietary process parameters, catering specialised or difficult-to-process materials. Enhanced automation and safety features are standard, including a fully enclosed and automated powder filtration design, and modular capacity for running up to eight jobs sequentially without operator intervention, all of which underscore a focus on productivity, safety, and reduced maintenance.

Additive Industries CEO Mark Massey emphasised the system’s core philosophy of delivering market-leading quality and productivity: “Based on the feedback of our valuable global customer base we have built this new system from the proven DNA of our MetalFab product portfolio with a key focus on the needs of our demanding users in the space, aerospace, automotive, and high-tech sectors who are looking to push productivity further in their manufacturing operations, where no compromise in quality is acceptable. The MetalFab 420K delivers this.”

The system has already proven its mettle during a rigorous six-month beta test programme conducted on the production floor of Stoke Space, a major, demanding US-based customer within the space sector, where productivity levels reportedly exceeded expectations. “Additive manufacturing plays a critical role in our manufacturing and production efforts,” says Kunal Naik, Senior Manager, Additive Manufacturing & Machine Shop at Stoke Space. “The MetalFab 420K gives us the productivity, precision, and reliability we need to move quickly from design iteration to flight hardware. Additive Industries has been a strong partner throughout the beta programme, and this next step reflects our confidence in the system’s readiness for production.”

Following the successful beta programme, Stoke Space invested in five MetalFab 420K production systems, expanding its additive manufacturing capacity and reinforcing its commitment to advanced, high-rate production.

The MetalFab 420K is commercially available, with Additive Industries currently accepting orders for Q2 2026 delivery slots.